-

Home

- Products

-

Case

- Factory Show

- News

-

video

- About Us

-

Contact Us

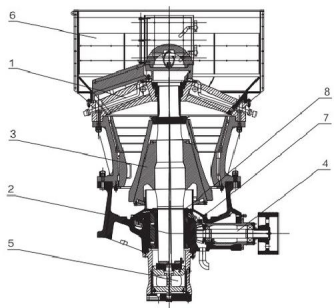

Diagram of DP CH Series Single Cylinder Hydraulic Cone Crusher

1. Upper frame 2. Lower frame 3. Broken cone

4. Driving part 5. Hydraulic cylinder 6. Feeding device

7. Eccentric sleeve 8. Sealing part

Introduction of DP CH Series Single Cylinder Hydraulic Cone Crusher

The DP CH series single cylinder hydraulic cone crusher produced by Shenyang Dapeng Heavy Equipment has reached the internationally leading technical level and realized fully intelligent control. The structure of DP CH single cylinder cone crusher makes the equipment adjustment extremely convenient. Even during the operation of the equipment, the discharge opening can be easily adjusted. The intelligent automatic control system keeps the cone crusher in the best working state at all times and realizes the automatic compensation function for the inner and outer cone liners. We can accurately set and adjust the size of the discharge opening from the operation panel, and also single cylinder cone crusher automatically complete the compensation for inner and outer cone liner of worn parts through several buttons on the operation panel. At the same time, due to the adoption of the single cylinder mechanical structure, the entire structure is very compact, greatly reducing the oil pipes and oil circuit and external adjustment structures. Therefore, the DP CH series single cylinder hydraulic cone crusher of our company has a simple and smooth appearance, small size, light weight, yet the production capacity greatly enhanced. This has opened a new era in the development of cone crushers in China.

DP CH series single cylinder hydraulic cone crusher is a high-efficiency crushing solution engineered for modern mining and construction demands. DP CH series single cylinder hydraulic cone crusher enables dynamic cone positioning while integrating multiple intelligent functions: CSS adjustment, automated chamber cleaning, tramp iron protection, and overload safeguards-ensuring operational simplicity and safety in extreme working conditions.

DP CH Series Single Cylinder Hydraulic Cone Crusher: Engineering Advantages

1. World-Class DP CH Series Single Cylinder Hydraulic Cone Crusher Technology

Featuring internationally patented hydraulic architecture, the DP CH series single cylinder cone crusher delivers unmatched operational reliability and optimized particle morphology through precision-engineered intergranular crushing dynamics.

2. Modular Performance Customization of DP CH series single cylinder cone crusher

Interchangeable chamber profiles for DP CH series single cylinder hydraulic cone crusher (multiple standard configurations)

Adjustable eccentric throw (wide operational range)

Enables flexible capacity adaptation to match specific ore characteristics and production targets.

3. Intelligent Hydraulic Optimization of single cylinder cone crusher

Real-time CSS adjustment under load with high precision

Continuous operation in fully choked feeding conditions

Significantly reduces wear part consumption compared to conventional systems.

4. Maintenance-Forward Design of CH Series

Top-access service architecture (key components of CH series are accessible without disassembly)

Integrated hydraulic diagnostics with fail-safe overload protection

Streamlines maintenance workflows for efficient servicing.

Technical parameters of DP CH Series Single Cylinder Cone Crusher

Model | Maximum Feeding Particle Size (mm) |

Adjustment range of Discharge port | Motor Power (kw) | Production Capacity (t/h) | Equipment Weight (t) |

DPCH430 | 185 | 5-38 | 160 | 126-344 | 9.2 |

DPCH440 | 215 | 6-44 | 250 | 114-395 | 21 |

DPCH660 | 275 | 10-51 | 315 | 177-662 | 31 |

DPCH870 | 300 | 10-70 | 630 | 588-1512 | 58 |

DPCH890 | 366 | 13-70 | 750 | 594-2181 | 85 |

DPCS430 | 360 | 19-51 | 132 | 91-344 | 12 |

DPCS440 | 450 | 25-34 | 250 | 267-601 | 20 |

DPCS660 | 560 | 38-83 | 315 | 318-1050 | 36 |

Model | Motor Installation Power (KW) | Cavity Type | Maximum Feeding particle Size (mm) | CH Series Standard Production Capacity (t/h) under the Tight Side Discharge Port css (mm) | ||||||

4 | 6 | 8 | 10 | 13 | 16 | 19 | ||||

DPCH 430 |

160 | EC | 185 |

|

|

|

| 69-108 | 75-150 | 80-161 |

C | 145 |

|

|

|

| 66-131 | 71-142 | 76-152 | ||

MC | 115 |

|

|

| 57 | 62-140 | 67-151 | 72-162 | ||

M | 90 |

|

|

| 64-84 | 69-131 | 75-142 | 80-152 | ||

MF | 75 |

|

| 61 | 65-106 | 70-115 | 76-124 | 81-126 | ||

| 50 |

| 48-78 | 51-83 | 54-88 | 59-96 | 63-103 | 68-105 | ||

DPCH 440 |

250 | EC | 215 |

|

|

|

|

| 114-200 | 122-276 |

C | 175 |

|

|

|

| 101 | 109-218 | 117-292 | ||

MC | 140 |

|

|

|

| 97-122 | 105-262 | 113-282 | ||

M | 110 |

|

|

|

| 117-187 | 126-278 | 136-298 | ||

MF | 85 |

|

|

| 114 | 124-227 | 134-245 | 144-263 | ||

| 70 |

|

| 90-135 | 96-176 | 104-191 | 112-206 | 120-221 | ||

DPCH 660 |

315 | EC | 275 |

|

|

| 209-505 |

| 177 | 190-338 |

C | 215 |

|

|

|

|

| 171-190 | 184-367 | ||

MC | 175 |

|

|

|

|

| 162-253 | 174-426 | ||

M | 135 |

|

|

|

|

| 197-295 | 211-440 | ||

MF | 115 |

|

|

|

| 192 | 207-369 | 222-396 | ||

F | 85 |

|

|

|

| 195-304 | 210-328 | 225-352 | ||

EF | 65 |

|

|

|

| 211-293 | 227-316 | 244-298 | ||

DPCH 870 |

630 | EC | 300 |

|

|

|

|

|

|

|

C | 240 |

|

|

|

|

|

| 406 | ||

MC | 195 |

|

|

|

|

|

| 443-740 | ||

M | 155 |

|

|

|

|

|

| 432-733 | ||

MF | 100 |

|

|

|

|

| 398-694 | 421-716 | ||

| 90 |

|

|

|

| 357-595 | 385-656 | 414-704 | ||

EF | 80 |

|

|

|

| 304-517 | 328-558 | 352-598 | ||

DPCH 890 |

750 | EC | 366 |

|

|

|

|

|

|

|

C | 327 |

|

|

|

|

|

|

| ||

MC | 259 |

|

|

|

|

|

| 542-817

| ||

| Model | Cavity Type | CH Series Standard Production Capacity (t/h) under the Tight Side Discharge Port css (mm) | ||||||||||||

22 | 25 | 32 | 38 | 44 | 51 | 57 | 64 | 70 | |||||||

DPCH 430 | EC | 86-171 | 91-182 | 104-208 | 115-208 |

| |||||||||

81-162 | 86-173 | 98-197 | 109-150 |

| |||||||||||

MC | 77-173 | 82-184 | 93-145 |

| |||||||||||

M | 86-162 | 91-154 | 104 |

| |||||||||||

MF | 87-114 | 92 |

| ||||||||||||

72-95 | 77 |

| |||||||||||||

DPCH 440 | EC | 131-294 | 139-313 | 159-357 | 175-395 | 192-384 |

| ||||||||

125-312 | 133-332 | 151-378 | 167-335 | 183-229 |

| ||||||||||

MC | 120-301 | 128-320 | 146-328 | 161-242 |

| ||||||||||

M | 145-318 | 154-339 | 176-281 | 194 |

| ||||||||||

MF | 153-281 | 163-299 | 186-248 |

| |||||||||||

129-236 | 137-251 | 156-208 |

| ||||||||||||

DPCH Series Crusher |

DPCH 660 | EC | 203-436 | 216-464 | 246-547 | 272-605 | 298-662 | 328-511 |

| ||||||

196-480 | 209-510 | 238-582 | 263-643 | 288-512 | 317-353 |

| |||||||||

MC | 186-455 | 198-484 | 226-552 | 249-499 | 273-364 |

| |||||||||

M | 226-470 | 240-500 | 274-502 | 302-403 |

| ||||||||||

MF | 237-423 | 252-450 | 278-451 | 318-363 |

| ||||||||||

241-376 | 256-400 | 292-401 | 323 |

| |||||||||||

EF | 261-290 |

| |||||||||||||

DPCH 870 | EC | 448-588 | 477-849 | 544-968 | 601-1070 | 658-1172 | 725-1291 | 782-1393 | 849-1512 | 906-1331 | |||||

C | 483-806 | 511-893 | 525-1018 | 581-1125 | 636-1232 | 700-1357 | 756-1464 | 820-1461 | 876-1286 | ||||||

MC | 476-793 | 502-857 | 522-994 | 544-1055 | 596-1155 | 657-1272 | 708-1373 | 769-1370 | 821-1206 | ||||||

M | 468-786 | 495-836 | 519-953 | 533-1054 | 558-1154 | 592-1271 | 686-1372 | 710-1248 | 765-1098 | ||||||

MF | 454-765 | 482-814 | 507-928 | 522-942 | 538-1021 | 572-1070 |

|

|

| ||||||

| 442-752 | 470-800 | 495-912 | 517-857 | 529-788 |

|

|

|

| ||||||

EF | 376-639 | 405-710 | 455-775 | 503-728 | 551-669 |

|

|

|

| ||||||

DPCH 890 | EC |

| 594-859 | 649-1309 | 696-1446 | 743-1584 | 798-1745 | 846-1883 | 801-2043 | 748-2181 | |||||

C | 697 | 622-974 | 682-1404 | 732-1552 | 783-1700 | 842-1873 | 893-2020 | 952-2193 | 812-2140 | ||||||

MC | 625-952 | 689-1232743-1404 | 790-1552 | 836-1700 | 891-1873 | 937-2020 | 992-2005 | 963-1739 | |||||||

Note: The above parameter table is for reference only.

The actual production capacity is determined by the type of materials and production conditions.

Working principle of DP CH Series Single Cylinder Hydraulic Cone Crusher

DP CH series Single Cylinder Cone Crusher realizes the rotation of the moving cone through the eccentric sleeve driven by the motor, alternately approaches and moves away from the fixed cone, performs lamination crushing, and produces uniform cubic particles. The hydraulic system of CH series Single Cylinder Hydraulic Cone Crusher automatically adjusts the discharge port when encountering unbreakable objects or overload, protects the equipment and discharges foreign matter, while the lubrication system ensures that key components are fully lubricated, reduces wear and extends the life of the equipment.

Application scenarios of DP CH Series Single Cylinder Hydraulic Cone Crusher

The DP CH Series Single Cylinder Cone Crusher demonstrates exceptional versatility in processing medium-to-high compressive strength materials, including iron ore, limestone, and granite. DP CH Series Single cylinder cone crusher robust design serves critical roles across:

Mineral extraction: Metalliferous/non-metalliferous quarries

Aggregates production: Sand/gravel resource utilization

Industrial processing: Construction materials manufacturing, infrastructure development, and heavy machinery applications.