-

Home

- Products

-

Case

- Factory Show

- News

-

video

- About Us

-

Contact Us

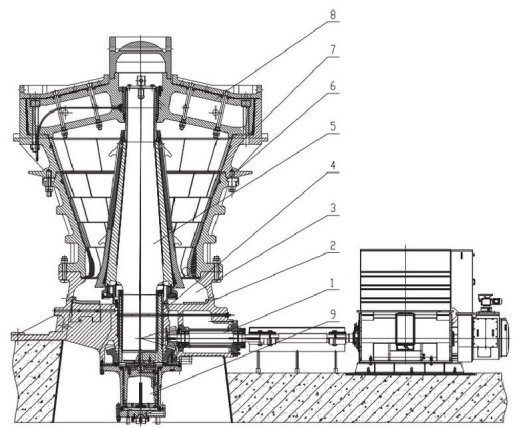

Diagram of PXZ Rotary Crusher, PXZ Gyratory Crusher

1. Driving part 2. Engine base 3. Engine base guard plate

4. Eccentric sleeve 5. Moving cone 6. Middle frame body

7. Upper frame body 8. Beam part 9. Cylinder part

Introduction of PXZ Hydraulic Rotary Crusher, PXZ Gyratory Crusher

Dapeng Heavy's PXZ rotary crusher (PXZ Crusher) is mainly applied in large and ultra-large primary crushing. PXZ crusher has unique crushing chamber design of the DP series can ensure the best production capacity. Compared with traditional hydraulic crusher, the PXZ hydraulic rotary crusher (PXZ Crusher) has higher crushing efficiency, lower cost, easy maintenance and adjustment. PXZ hydraulic rotary crusher (PXZ crusher) can provide customs with an intelligent ultra-large production capacity coarse crushing solution. PXZ hydraulic rotary crusher (PXZ Crusher) is widely used in the fields of black and non-ferrous mines and sand and gravel aggregates. The PXZ hydraulic rotary crusher (PXZ Crusher) has equipped with an intelligent control system, PXZ hydraulic rotary crusher is not only improves the automation level but also maximizes the stability of equipment operation and improves the convenience of operation and maintenance.

PXZ hydraulic gyratory crusher is one of the main equipment used for crushing ore or rock. PXZ hydraulic crusher has the characteristics of high production capacity and uniform product particle size. The PXZ hydraulic rotary crusher is now widely used in metallurgy, building materials, chemical industry, hydropower and other industries.

Features of PXZ Hydraulic Rotary Crusher, PXZ Hydraulic Gyratory Crusher

1. PXZ rotary crusher has a unique deep-chamber crushing chamber and a long feed port design, which allows for smooth feeding and continuous crushing. This PXZ rotary crusher has the advantages of large processing capacity, high crushing efficiency, large crushing ratio, uniform finished product particle size, convenient maintenance, less liner wear, and also the PXZ crusher will be more economical .

2. PXZ gyratory crusher (PXZ Crusher) has a spindle positioning control system. PXZ hydraulic gyratory crusher can easily adjust the spindle to compensate for the wear of the liner and control the product particle size.

3. PXZ rotary crusher has a balancing cylinder system that prevents spindle vibration. When the hydraulic crusher is overloaded, PXZ crusher can automatically lower the spindle to avoid the impact of spindle vibration on the equipment when the equipment enters oversized materials, ensuring safe and stable operation.

4. PXZ gyratory crusher has a matching positive pressure dust prevention system. PXZ gyratory crusher can effectively prevent dust from entering the eccentric device and transmission device of the equipment, which can extend the service life of the whole machine.

5. PXZ rotary crusher has high-strength super-heavy frame, integral body shaft and high-performance bearings, which ensures longer service life and safer and more reliable operation under various harsh working conditions.

Technical Parameters of PXZ Rotary crusher (PXZ Crusher)

Model |

Minimum Discharge Port (mm) |

Maximum Feed Particle Size (mm) | Ajusting Range of Discharge Port (mm) | Production Capacity (t/h) | Motor Power (kw) |

PXZ-0913 | 130 | 750 | 130-160 | 625-770 | 210 |

PXZ-1216 | 160 | 1000 | 160-190 | 1250-1480 | 400 |

PXZ-1417 | 170 | 1200 | 170-200 | 1750-2260 | 560 |

PXZ-1618 | 190 | 1350 | 190-215 | 2400-3350 | 800 |

DP-4265 | 152 | 1066 | 152-177 | 2354-2893 | 450 |

DP-5065 | 152 | 1270 | 152-177 | 2414-2958 | 450 |

DP-5475 | 152 | 1370 | 152-177 | 2908-3170 | 600 |

DP-6275 | 152 | 1575 | 152-177 | 2913-3846 | 600 |

DP-6089 | 177 | 1525 | 177-203 | 4576-5851 | 750 |

DP-7089 | 177 | 1780 | 177-203 | 5051-7033 | 900 |

Note: The above parameter table is for reference only.

The actual production capacity is determined by the type of materials and production conditions.

Working principle of PXZ Hydraulic Rotary Crusher, PXZ Gyratory Crusher

PXZ rotary crusher (PXZ Crusher) adopts a large-angle long crushing surface design, and cooperates with the optimized stroke and speed to meet different coarse crushing needs; the PXZ rotary crusher (PXZ crusher) crushing chamber design is improved, the production capacity is strong, the feed particle size is large, and the liner life is long; the processing capacity of the PXZ crusher can be adjusted to meet different crushing process requirements. PXZ rotary crusher (PXZ gyratory crusher) equipped with a large-diameter integral main shaft and improved bearing casting technology, the equipment can carry out continuous production operations; the main shaft and the moving cone are integrally cast to prevent the moving cone from loosening during use and reduce downtime; the moving cone locking thread is located on the replaceable main shaft sleeve, the main shaft has no thread and no stress concentration, and the body strength is improved. The PXZ rotary crusher (PXZ gyratory crusher, PXZ Crusher) use an automated control system can detect each link of the equipment operation in real time, facilitate the control and maintenance of the equipment, and reduce maintenance costs; it can automatically diagnose operating faults and record equipment production information; the PXZ crusher can also optimize the equipment's operating parameters according to the equipment's operating conditions to help the equipment stabilize production.

Parts of PXZ Hydraulic Rotary Crusher, PXZ Gyratory Crusher(PXZ Crusher)

Application scenarios of PXZ Rotary Crusher (PXZ Crusher)

1. Large and medium-sized ore dressing plants and large quarries: PXZ crusher is widely used in large and medium-sized ore dressing plants and large quarries for crushing hard and medium-hard ores due to its large production capacity and continuous crushing of ore.

2. Coarse crushing operation: PXZ crusher is a coarse crusher. Compared with jaw crusher, its advantage is that the crushing process is carried out continuously along the annular crushing chamber, so it has high productivity, low power consumption and stable operation.

3. Ore dressing plants in large metallurgical mines: Most of the ore dressing plants in large metallurgical mines use hydraulic rotary crusher instead of jaw crusher for coarse crushing, because the production capacity of PXZ gyratory crusher is 3~4 times higher than a jaw crusher.

4. Industrial coarse crushing of various hard materials: hydraulic crusher is a typical equipment for coarse crushing of various hard materials in large mines and other industrial sectors.

5. Continuous crushing and ore discharging: Since PXZ gyratory crusher (PXZ crusher) is continuous crushing and ore discharging, it has greater production capacity than jaw crusher.

In summary, PXZ Rotary Crusher (PXZ crusher) is mainly used in large-scale mines, mineral processing plants, quarries and other industrial fields due to its high production capacity and suitability for crushing hard materials, especially in situations where large amounts of hard materials need to be processed.