- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

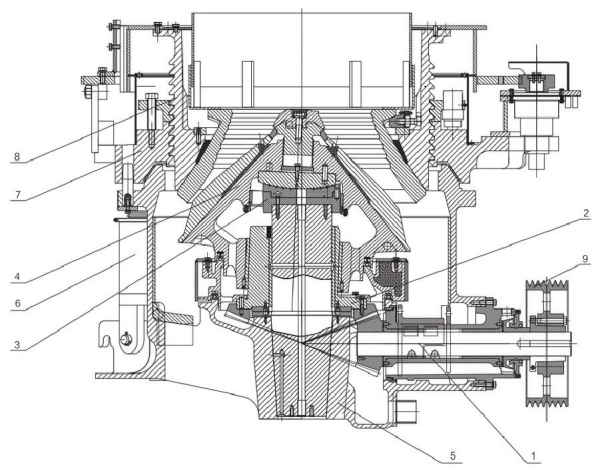

Diagram of DPHP Multi Cylinder Cone Crusher

1. Driving part 2. Eccentric sleeve 3. Ball bearing

4. Crushing cone 5. Frame part 6. Safety device

7. Supporting sleeve 8. Adjusting ring 9. Belt pulley

Introduction of DPHP Multi Cylinder Hydraulic Cone Crusher (DPHP Cone Crusher)

DPHP multi-cylinder hydraulic cone crusher (DPHP Cone Crusher) is an advanced crushing equipment that integrates high efficiency, excellent particle size, and automated operation. DPHP Cone Crusher adopts multi cylinder hydraulic design and laminated crushing principle to achieve efficient secondary crushing and crushing of medium-hard and above materials. Fine crushing, with DPHP Cone Crusher's precise hydraulic discharge opening adjustment, quick liner replacement and high load capacity, DPHP multi cylinder hydraulic cone crusher (DPHP Crusher) suitable for mining, building materials and other industries. With DPHP Cone Crusher's excellent performance and reliability, DPHP Cone Crusher has shown significant competitive advantages in the crushing field.

Advantages of DPHP Multi Cylinder Hydraulic Cone Crusher (DPHP Cone Crusher)

1. DPHP multi-cylinder hydraulic cone crusher (DPHP Cone Crusher) adopts an optimized laminated crushing chamber and matching high swing frequency and large stroke to achieve DPHP Cone Crusher's multi-particle laminated crushing, significantly increasing the fine material ratio and cube content of the product. The needle and flake materials are reduced to a great extent and the finished grain shape is improved.

2. Use DPHP Cone Crusher's hydraulic system to adjust DPHP Cone Crusher's fixed cone liner to achieve precise adjustment of the discharge port. At the same time, DPHP Cone Crusher's hydraulic system is convenient and reliable, DPHP Cone Crusher can provide safe and effective overload protection, DPHP Cone Crusher can reduce or even avoid downtime, and DPHP Cone Crusher can greatly reduce production costs.

3. DPHP multi cylinder cone crusher (DPHP Crusher) adopts a separate design of DPHP Cone Crusher's main shaft and the moving cone. DPHP Cone Crusher's main shaft and DPHP Crusher's lower frame are integrated into a whole through taper interference fit, so that the diameter of DPHP Crusher's main shaft can be designed to be large enough to withstand a large load. DPHP multi cylinder cone crusher (DPHP Crusher) is able to break very hard materials.

Technical Parameters of DPHP multi cylinder cone crusher (DPHP Crusher)

Model | Cavity Type | Open side feed port (mm) | Standard |

Opening side feed port (mm) | Short head Closed side feeding port (mm) | Tight discharge port (mm) | Motor power (kw) | Main machine weight (t) | Operating weight (t) | ||

Closed side feed port (mm) | Tight discharge port (mm) | ||||||||||

DPHP 300 | Extra Coarse | EC | 267 | 233 | 23 | / | / | / |

220 |

17.5 |

21.8 |

coarse | C | 240 | 211 | 20 | 123 | 77 | 10 | ||||

medium | M | 190 | 150 | 16 | 100 | 53 | 8 | ||||

fine | F | 148 | 107 | 13 | 72 | 25 | 6 | ||||

DPHP 400 | Extra Coarse | EC | 333 | 299 | 30 | / | / |

315 |

27.5 |

32.5 | |

coarse | C | 292 | 252 | 25 | 143 | 92 | 10 | ||||

medium | M | 245 | 198 | 20 | 107 | 52 | 8 | ||||

fine | F | 164 | 111 | 14 | 104 | 40 | 6 | ||||

DPHP 500 | Extra Coarse | EC | 372 | 335 | 30 | / | / |

400 |

37.5 |

43.5 | |

coarse | C | 322 | 286 | 25 | 152 | 95 | 13 | ||||

medium |

M |

246 |

204 |

20 |

116 |

57 |

10 | ||||

fine | F | 182 | 133 | 16 | 105 | 40 | 8 | ||||

DPHP 800 | Extra Coarse | EC | 375 | 353 | 32 | / | / |

630 |

88.6 |

97.6 | |

coarse |

C |

340 |

297 |

32 |

210 |

155 |

13 | ||||

medium | M | 308 | 267 | 25 | 150 | 92 | 10 | ||||

fine | F | 264 | 219 | 16 | 98 | 33 | 5 | ||||

Working principle of DPHP Multi Cylinder Cone Crusher (DPHP Crusher)

The working principle of DPHP Crusher is to use the motor to drive DPHP Crusher's transmission shaft and DPHP Crusher's eccentric sleeve to make DPHP Crusher's movable cone rotate and swing around DPHP Crusher's main shaft to squeeze and bend the materials. At the same time, DPHP Crusher's hydraulic system is used to realize automatic adjustment of DPHP Crusher's discharge port and overload protection, ensuring the efficiency and safety of DPHP Crusher when processing hard materials.

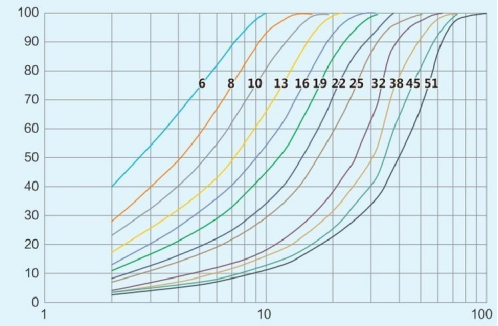

DPHP multi cylinder cone crusher granularity curve

FAQ of DPHP multi cylinder cone crusher (DPHP Crusher)

Q1: Is DPHP Multi-Cylinder Hydraulic Cone Crusher (DPHP Crusher) suitable for primary crushing?

A1: No, it is specifically designed for secondary and tertiary crushing. Primary crushing (processing large raw materials into coarse-grained products) requires equipment with larger feeding capacities (e.g., jaw crushers, gyratory crushers). DPHP Multi Cylinder Cone Crusher (DPHP Crusher) is optimized to take coarse materials from primary crushing and refine them into medium or fine-grained products, which aligns with DPHP multi cylinder hydraulic cone crusher's hydraulic control and cavity design strengths.

Q2: How do you ensure DPHP Cone Crusher matches our material's hardness?

A2: First, we collect detailed information about your material's hardness (e.g. compressive strength) and other properties (e.g. abrasiveness). If needed, we can conduct small-scale crushing tests in our laboratory using samples of your material to verify DPHP Multi Cylinder Cone Crusher (DPHP Crusher)'s performance. We then recommend the appropriate wear part materials (e.g. high-chromium alloy for ultra-hard ores) and cavity type to ensure PDHP Multi Cylinder Cone Crusher (DPHP Crusher) operates efficiently and durably.

Q3: Can DPHP Multi Cylinder Cone Crusher (DPHP Crusher) be integrated into an existing production line?

A5: Yes. During the selection phase, our team will analyze your existing production line's layout, capacity, and upstream/downstream equipment (e.g., feeders, conveyors) to ensure DPHP Cone Crusher (DPHP Crusher)'s feeding size, output, and installation dimensions match seamlessly. We can also provide modified designs (e.g., adjusting the crusher's height or interface) if needed to fit your current setup.

Our Service of DPHP Crusher

We provide end-to-end, customized support to maximize the value of your DPHP Multi-Cylinder Hydraulic Cone Crusher (DPHP Crusher) investment, covering every stage from pre-purchase to long-term operation:

1. Customized Selection Consulting of DPHP Crusher

Our technical team conducts in-depth analysis of your industry (mining, construction, aggregate, etc.), material properties (hardness, moisture content, particle size distribution), and production objectives (product application, output requirements). Based on this, we recommend the most suitable DPHP Hydraulic Cone Crusher (DPHP Crusher) model, matching DPHP Crusher with appropriate crushing cavity types and auxiliary equipment to ensure optimal compatibility with your production line.

2. After-Sales Support & Spare Parts Supply of DPHP Crusher

Our global service network provides timely responses to maintenance needs—including on-site repairs for complex issues and remote technical guidance (via video calls, online diagnostics) for urgent problems. We also supply genuine spare parts (e.g., wear plates, hydraulic cylinders) with stable inventory, ensuring fast delivery to reduce equipment downtime.

3. Efficient Logistics & Delivery

Partnering with top logistics providers, we manage full-cycle services including packaging, port loading under FOB terms. Ensure on-time, safe delivery to shorten commissioning cycles.

Our company

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+ m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mills, heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.