- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

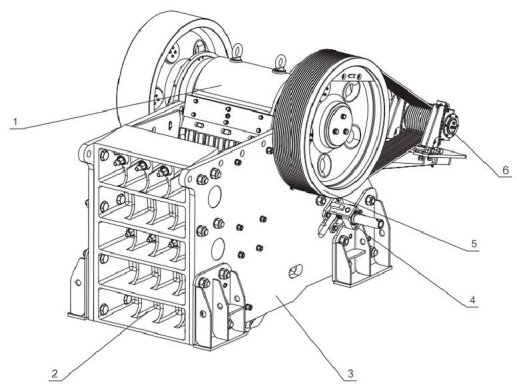

Diagram of PEV Jaw Crusher

1.Movable jaw 2.Front baffle 3. Wall panel

4.Regulating device 5. Pulley 6. Motor part

Introduction of PEV Jaw Crusher (primary crusher)

PEV jaw crusher is a new type of high-performance hydraulically adjusted jaw crusher (primary crusher) developed on the basis of ordinary jaw crusher (primary crusher) and combined with internationally advanced jaw crusher collar technology. Due to the use of internationally advanced V-type crushing chamber technology, combined with a new frame and movable jaw structure, hydraulic adjustment and centralized automatic lubrication, the equipment performance is greatly improved and the operation and maintenance are more convenient.

Advantages of PEV Jaw Crusher (primary crusher)

1. The V-shaped crushing chamber has a large crushing capacity.

2. The cast-welded frame is strong and light.

3. The high-strength movable jaw has a greater bearing capacity.

4. The hydraulic wedge adjustment is easy to operate and maintain.

5. Simple and quick installation: shock-absorbing pads and limit blocks are used, and no anchor bolts are required, which has better stability and longer service life.

6. Integrated installation: The motor frame is installed on the jaw crusher (primary crusher) when it leaves the factory, which is integrated with the crusher, reducing the installation space and the length of the V-belt of the crusher. The crusher moves synchronously with the motor, increasing its service life.

7. Structural optimization: After optimizing the structure, the new jaw crusher (primary crusher) has a larger stroke than the ordinary crusher, so its output is higher.

8. Convenient adjustment: Mechanical and hydraulic wedge adjustments are used. Jaw crusher (primary crusher) gap can be quickly adjusted whether it is working or stopped, without adding pads, and the efficiency is higher.

9. Larger bearings: The new jaw crusher (primary crusher) uses 4 bearings of the same size, which are larger and have a longer life than other ordinary crusher models of the same specifications.

Technical Parameters of PEV Jaw Crusher (primary crusher)

| PEV Jaw Crusher | |||||||

| Model | PEV 500x750 | PEV 600x900 | PEV 750x1060 | PEV 950x1250 | PEV 1200x1600 | PEV 1500x2000 | |

| Width of Feeding Port (mm) | 750 | 900 | 1060 | 1250 | 1600 | 2000 | |

| Pepth of feeding port (mm) | 500 | 600 | 750 | 950 | 1200 | 1500 | |

| Motor (kw) | 55-75 | 75-90 | 132 | 160 | 250 | 400 | |

| Weight (kg) | 9080 | 14145 | 23800 | 46324 | 79500 | 131000 | |

| Production Particle size(mm) | Tight Side Discharge Port (mm) | ||||||

| 0-60 | 40 | 55-80 | |||||

| 0-75 | 50 | 70-90 | |||||

| 0-90 | 60 | 80-110 | 120-155 | ||||

| 0-105 | 70 | 105-130 | 140-180 | 155-200 | |||

| 0-120 | 80 | 120-150 | 160-210 | 175-230 | |||

| 0-135 | 90 | 130-170 | 180-235 | 200-260 | |||

| 0-150 | 100 | 150-190 | 200-260 | 220-290 | 290-380 | ||

| 0-185 | 125 | 190-260 | 250-325 | 280-365 | 350-455 | ||

| 0-225 | 150 | 250-340 | 300-390 | 335-435 | 410-535 | 520-675 | |

| 0-260 | 175 | 350-455 | 390-510 | 470-610 | 595-775 | 760-990 | |

| 0-300 | 200 | 445-580 | 530-690 | 675-880 | 855-1110 | ||

| 0-340 | 225 | 590-770 | 750-975 | 945-1230 | |||

| 0-375 | 250 | 650-845 | 825-1070 | 1040-1350 | |||

| 0-410 | 275 | 900-1170 | 1130-1470 | ||||

| 0-450 | 300 | 980-1275 | 1225-1590 | ||||

| 315r/min | 294r/min | 249r/min | 215r/min | ||||

Note: The above parameter table is for reference only. The actual production capacity is determined by the type of materials and production conditions. | |||||||

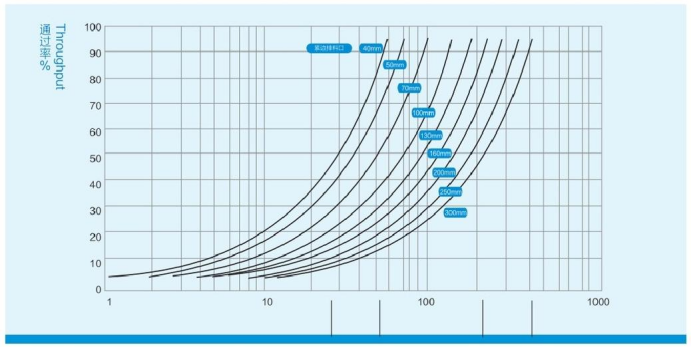

Product granularity curve of PEV jaw crusher (primary crusher)

Application scenarios of PEV Jaw Crusher (primary crusher)

1. Mining industry: PEV jaw crusher (primary crusher) is suitable for coarse, medium and fine crushing of various ores or rocks with compressive strength not more than 300Mpa, and is an ideal crushing equipment for mining resources.

2. Sand and gravel field: In the sand and gravel field, PEV jaw crusher (primary crusher) is used to crush stones of various hardness, such as river pebbles, granite, basalt, etc., to produce sand and gravel aggregates required for construction and engineering.

3. Cement plant: In cement production, PEV jaw crusher (primary crusher) is used to crush raw materials such as limestone to meet the requirements of raw material particle size in the cement production process.

4. Road construction industry: A large amount of crushed stone and sand are required in road construction. PEV jaw crusher (primary crusher) can provide primary crushing of these materials to meet the needs of road construction.

5. Metallurgical industry: In the metallurgical industry, PEV jaw crusher (primary crusher) is used to crush various ores to provide suitable raw material particle size for the smelting process.

FAQ

1. What crushing stages is the PEV Jaw Crusher designed for?

It is a high-performance hydraulically adjusted jaw crusher (primary crusher) , primarily engineered for **primary crushing** of various ores and rocks with compressive strength up to 300Mpa. Its optimized V-shaped crushing chamber and large stroke design also enable efficient processing for medium-crushing scenarios in mining, aggregate, and construction projects.

2. What are the key advantages of the PEV Jaw Crusher over conventional jaw crushers (primary crusher) ?

The core advantages include:

Larger crushing capacity with advanced V-type chamber technology;

Lightweight yet robust cast-welded frame and high-strength movable jaw for superior load-bearing;

Easy operation via hydraulic wedge adjustment (supports gap tuning both in operation and shutdown);

Hassle-free installation with shock-absorbing pads and limit blocks (no anchor bolts needed);

Longer service life with 4 oversized bearings and integrated motor-crusher design.

3. How to adjust the discharge gap of the PEV Jaw Crusher?

It adopts dual adjustment modes: mechanical and hydraulic wedge adjustment. Unlike traditional pad-based adjustment methods, the PEV model allows quick, tool-free gap tuning whether the equipment is running or stopped, significantly improving operational efficiency and reducing downtime.

4. Is the PEV Jaw Crusher (primary crusher) suitable for mobile crushing applications?

Yes. Its integrated design (motor frame pre-installed at the factory) reduces installation space and V-belt length, ensuring synchronous movement of the motor and crusher. The anchor-bolt-free installation also enhances stability, making it ideal for fixed production lines and mobile crushing stations alike.

5. What factors affect the actual production capacity of the PEV Jaw Crusher (primary crusher) ?

Actual capacity depends on material properties (hardness, humidity, particle size), tight-side discharge port setting, and feeding uniformity. The equipment’s optimized structure and larger stroke deliver higher output than conventional crushers of the same specification under identical working condition.

Our service

1. Customized Sizing Service

Targeting the production characteristics and actual needs of different industries, we assemble a professional technical team to conduct one-on-one consultations. By in-depth analyzing key factors such as capacity goals, material properties, and site conditions, we precisely match the optimal equipment configuration to avoid capacity waste or inadequate adaptation, maximizing return on investment (ROI).

2. Efficient Logistics & Delivery

FOB (Free On Board) is our preferred logistics term. We collaborate with high-quality logistics partners to coordinate the entire process, including equipment packaging, port loading, and compliant customs clearance. This ensures the equipment is delivered to the designated destination on time and safely, shortening the production launch cycle.

3. Personalized Upgrade Solutions

Addressing the needs of capacity expansion and energy-saving transformation for existing production lines, we provide equipment upgrade and technical optimization plans. These solutions help enhance production capacity, reduce energy consumption, and flexibly adapt to industry development and changes in market demand.

Our Company

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+ m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mills, heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.