- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

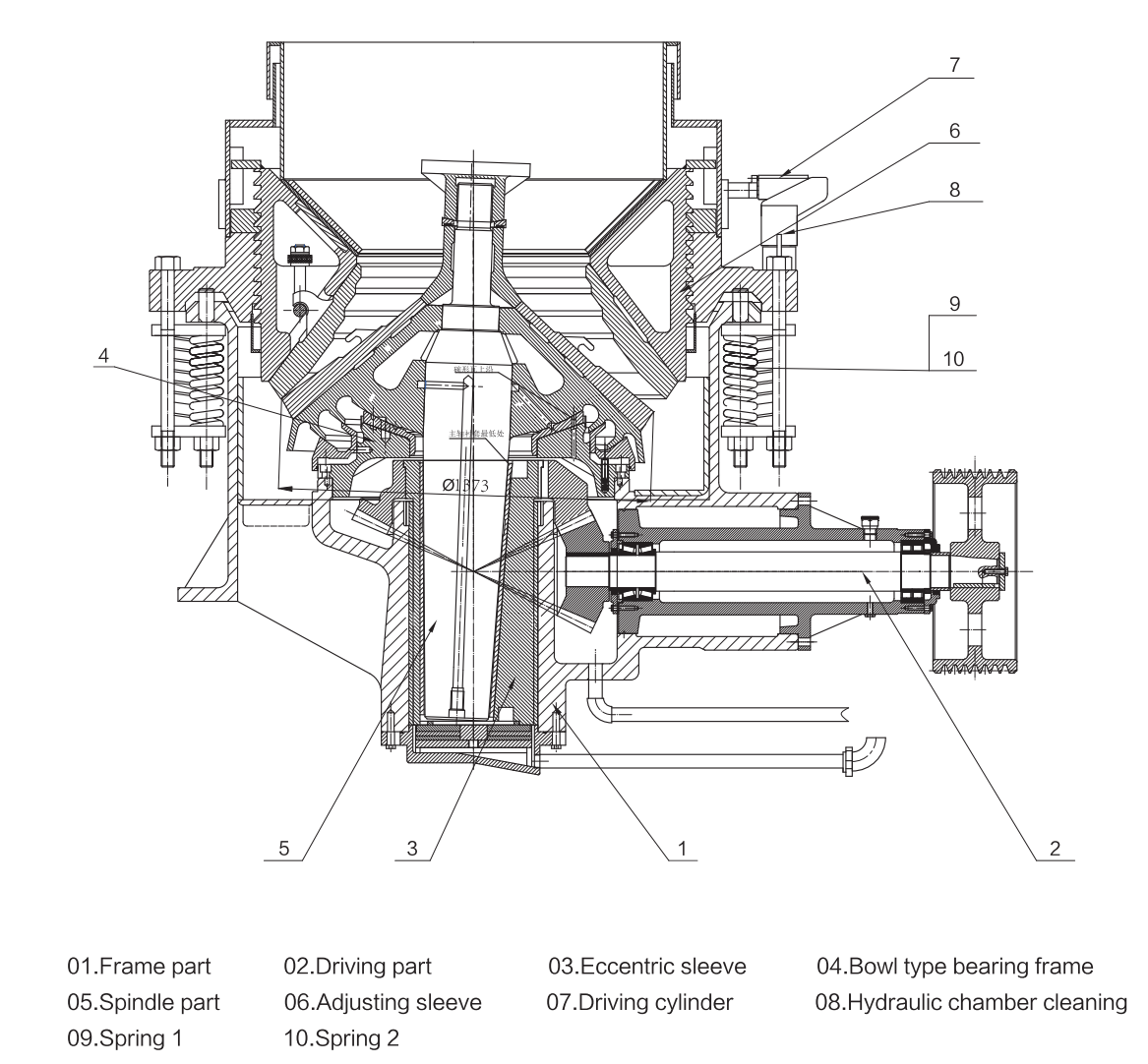

Diagram of PYF Compound Cone Crusher

Introduction of PYF Compound Cone Crusher

PYF Cone Crusher is a modern high-performance crusher that integrates high swing frequency, optimized cavity type and reasonable stroke, which is designed and developed by our company based on the introduction and absorption of foreign Simons cone technology and the principle of laminated crushing and the concept of more crushing and less grinding according to customer needs. The perfect combination of high-performance crushing cavity type and high crushing frequency greatly improves the processing capacity of the PYF cone crusher. Because of the adoption of the laminated crushing principle, the crushed products are mostly cubic structures, which greatly reduces the needle-like materials.

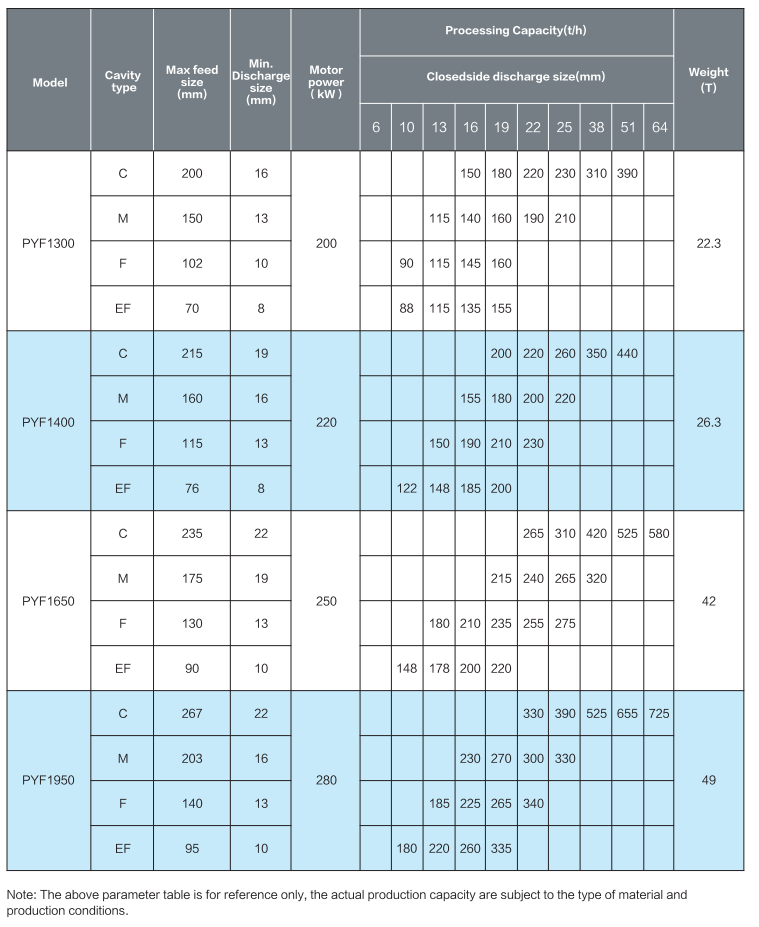

Technical Parameters of PYF Compound Cone Crusher

Advantages of PYF Compound Cone Crusher

The PYF compound cone crusher has a simple structure, is easy to operate and maintain, and the discharge port is easy and quick to adjust, saving time and effort during maintenance. In particular, the liner is easy to replace quickly, reducing downtime. PYF Cone Crusher is widely used in mining ore crushing, high-hardness rock material crushing, building material crushing, cement plants, sand and gravel yards, concrete mixing stations, dry mortar, power plant desulfurization, quartz sand, etc. PYF compound cone crusher is developed on the basis of digesting and absorbing various types of cone crushers with international advanced level in 1980s. PYF Cone Crusher's structure is obviously different from that of traditional cone crusher in design, and PYF Cone Crusher concentrates the main advantages of various types of cone crushers known so far.

Working principle of PYF Compound Cone Crusher

The working principle of PYF compound cone crusher is that the transmission shaft is driven by an electric motor, so that the crushing cone rotates and swings around the fixed point under the compulsion of the eccentric sleeve, causing the crushing wall to sometimes approach and sometimes leave the mortar wall fixed on the adjustment sleeve, thereby squeezing, grinding and bending the ore to achieve ore crushing. At the same time, when encountering unbreakable objects, overload protection is achieved through the spring safety system or hydraulic safety system, so that foreign matter can be discharged smoothly through the crushing chamber to ensure the safe operation of the equipment.

FAQ of PYF Cone Crusher

1. What capacity advantage does the PYF Cone Crusher have over conventional cone crushers?

Through optimized matching of crushing frequency and eccentric distance, PYF Cone Crusher enables faster, more rhythmic material compression, delivering significantly higher production capacity than traditional models.

2. Why is the particle shape of crushed materials superior?

Its strengthened laminated crushing design enhances inter-particle collision and friction in the chamber, producing predominantly cubic finished products—ideal for construction aggregates as they improve concrete performance.

3. What types of materials can the PYF Cone Crusher process?

It is specialized in handling various medium-to-high hardness materials, including granite, iron ore, copper ore, basalt, and other similar ores, ensuring efficient crushing of large raw lumps.

4. How to select the appropriate crushing chamber type of PYF Cone Crusher?

Each model offers four chamber options (coarse/medium/fine/ultra-fine). Choose based on your material characteristics, production scale, and the required finished particle size for optimal results.

5. Can PYF Cone Crusher be integrated into existing production lines?

Yes. It seamlessly adapts to both single-stage crushing processes and complex multi-stage crushing-screening systems, coordinating smoothly with jaw crushers, impact crushers, and other equipment.

6. How does the PYF Cone Crusher reduce vibration and noise during operation?

Structural optimization via CAD and finite element analysis, combined with high-strength heat-treated components, ensures rational force distribution and tight component fit, minimizing vibration and noise.

7. What overload protection measures does PYF Cone Crusher have?

Equipped with an intelligent overload protection system: sensors detect abnormal torque increases, and the system cuts power timely to safeguard the transmission unit and ensure operational safety.

8. Is the PYF Cone Crusher prone to chamber blockage?

No. Its optimized crushing chamber expands material passing area and improves flow trajectory, significantly reducing blockage risks while ensuring full crushing of each particle.

Our Service of PYF Compound Cone Crusher

We focus on providing professional support throughout your procurement and equipment commissioning process for the PYF Compound Cone Crusher, ensuring the equipment perfectly matches your production needs and starts operation smoothly.

1. Pre-Sales Customized Consultation of PYF Cone Crusher

Demand Matching & Model Selection: Our technical team will conduct in-depth communication to clarify your core requirements, including the type of material to be crushed (e.g., granite, iron ore, basalt), material hardness, required finished particle size, hourly output target, and site installation conditions (available space, power supply parameters).

If you need to integrate the crusher into an existing production line (such as a mining or aggregate production line), our team will analyze the parameters of your existing feeding, conveying, and screening systems to ensure seamless connection, avoiding material blockage or mismatched capacity.

Chamber Type Recommendation: Based on your production demands, we will provide professional suggestions on selecting the appropriate crushing chamber type (coarse/medium/fine/ultra-fine) to optimize crushing efficiency and product quality.

2. In-Sales Quality Control & Delivery Guarantee of PYF Cone Crusher

Production Progress Tracking: After order confirmation, we will regularly send you production progress reports, so that you can clearly know PYF Cone Crusher's production schedule and estimated delivery time.

Strict Quality Inspection: Each PYF Compound Cone Crusher undergoes multi-stage quality inspections during production, covering structural integrity, component fit, and performance testing, to ensure the product meets the specified quality standards.

Flexible Logistics Solutions: We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.). The equipment will be professionally packaged to prevent damage during transportation, ensuring it is delivered to your designated site intact and on time.

3. Technical Guidance & Documentation Support of PYF Cone Crusher

We provide comprehensive technical documents, including operation manuals, installation diagrams, and troubleshooting guides, which detail PYF Cone Crusher's working principle, operation steps, structural maintenance points, and common problem solutions for your reference.

If you need on-site technical guidance, our professional engineers can be dispatched to provide on-site installation and commissioning guidance, helping your team master the correct installation methods and key operation points.

Our Company

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mills, heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.