- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

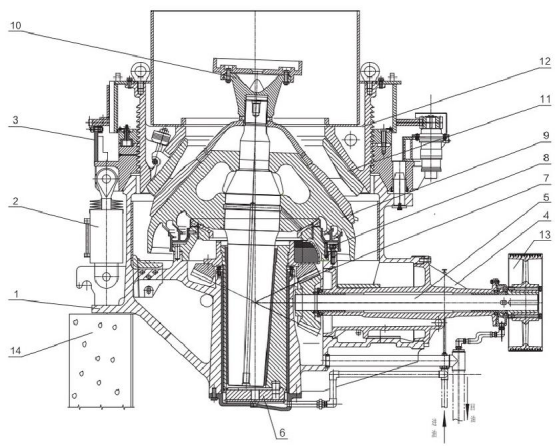

Diagram of PYH Multi Cylinder Hydraulic Cone Crusher

1. Frame body 2. Hydraulic part 3. Supporting sleeve

4. Drive shaft support part 5. Driving shaft 6. Thrust bearing

7. Eccentric sleeve 8. Bowl-shaped bearing part 9. Crushing cone

10. Material distributing tray part 11. Liner plate 12. Adjusting sleeve

13. Driving device 14. Basic part

Introduction of PYH Multi Cylinder Hydraulic Cone Crusher

PYH multi cylinder hydraulic cone crusher is an efficient and stable crushing equipment. PYH multi cylinder cone crusher has a wide range of applications, high production capacity and crushing efficiency, and is easy to operate and maintain. PYH multi cylinder cone crusher is an ideal choice for large-scale stone plants and mining crushing.

Advantages of PYH Multi-Cylinder Hydraulic Cone Crusher

1. High production efficiency: The PYH multi-cylinder hydraulic cone crusher uses layer compression crushing theory, has a scientific crushing cavity and large eccentricity design, and uses hydraulic cylinder pre-compression technology to achieve constant discharge port during the crushing process, ensuring high production efficiency, excellent product particle shape and low energy consumption.

2. High degree of automation: The automatic control system of PYH multi cylinder cone crusher can realize functions such as overload protection, iron protection, and discharge port adjustment, and monitor oil temperature, oil pressure, flow and other parameters in real time to ensure reliable operation of the equipment.

3. Wide adaptability: The PYH multi cylinder cone crusher has two different types: standard type and short head type. Each model corresponds to a variety of cavity types. The product grading can be adjusted by replacing parts such as liner and pulley to meet different needs.

Technical Parameters of PYH Multi Cylinder Hydraulic Cone Crusher

Model & specification |

Classifications |

Cavity type | Size of feed port(mm) |

Min. Discharge port size (mm) | Main motor (kw) | Disecharge size (mm)

|

capacity(t/h) | ||

Opening side | Closing side | ||||||||

PYH Cone Crusher D1607 |

H400 | short | fine | 70 | 35 | 6 |

240 | 6-13 | 110-220 |

PYH D1608 | medium | 89 | 54 | 6 | 6-19 | 145-325 | |||

PYH D1613 | rough | 133 | 98 | 10 | 10-25 | 200-353 | |||

PYH Cone Crusher D1614 | coarse | 158 | 117 | 13 | 13-25 | 265-353 | |||

PYH Cone Crusher B1620 |

H450 | standard | Fine | 209 | 188 | 16 | 16-38 | 190-345 | |

PYH B1624 | medium | 241 | 212 | 22 | 22-51 | 270-438 | |||

PYH B1626 | rough | 269 | 241 | 25 | 25-64 | 315-600 | |||

PYH COne Crusher B1636 | coarse | 368 | 331 | 38 | 38-64 | 450-600 | |||

PYH Cone Crusher D2110 |

H700 | short | Fine | 105 | 51 | 6 |

450 | 6-16 | 315-475 |

PYH D2113 | medium | 133 | 95 | 10 | 10-19 | 410-590 | |||

PYH D2117 | rough | 178 | 127 | 13 | 13-25 | 525-695 | |||

PYH Cone Crusher D2120 | coarse | 203 | 152 | 16 | 16-25 | 588-756 | |||

PYH Cone Crusher B2127 |

H750 | standard | Fine | 278 | 253 | 19 | 19-38 | 565-840 | |

PYH B2133 | medium | 334 | 303 | 25 | 25-51 | 705-1160 | |||

PYH B2136 | rough | 369 | 334 | 31 | 31-64 | 910-1450 | |||

PYH Cone Crusher B2146 | coarse | 460 | 425 | 38 | 38-64 | 1000-1550 | |||

PYH Cone Crusher D2512 |

H900 | short | Fine | 120 | 60 | 10 |

710 | 10-16 | 560-670 |

PYH D2515 | medium | 150 | 100 | 13 | 13-19 | 670-810 | |||

PYH D2519 | rough | 190 | 130 | 16 | 16-22 | 770-1000 | |||

PYH Cone Crusher D2522 | coarse | 220 | 160 | 19 | 19-25 | 920-1190 | |||

PYH Cone Crusher B2530 |

H950 | standard | Fine | 300 | 275 | 19 | 19-38 | 700-1200 | |

PYH B2535 | medium | 350 | 320 | 25 | 25-51 | 1050-1900 | |||

PYH B2541 | rough | 410 | 375 | 31 | 31-64 | 1300-2500 | |||

PYH Cone Crusher B2548 | coarse | 480 | 445 | 38 | 38-64 | 1500-2600 | |||

PYH Cone Crusher D2612 |

H1100 | short | Fine | 140 | 70 | 11 |

800/850 | 11-18 | 580-740 |

PYH D2616 | medium | 144 | 105 | 13 | 13-25 | 680-920 | |||

PYH D2618 | rough | 154 | 131 | 19 | 19-38 | 740-960 | |||

PYH Cone Crusher D2623 | coarse | 194 | 165 | 23 | 23-47 | 770-1030 | |||

PYH Cone Crusher B2624 |

H1150 | standard | Fine | 305 | 260 | 25 | 25-51 | 800-1650 | |

PYH B2632 | medium | 406 | 345 | 27 | 27-59 | 815-1750 | |||

PYH B2636 | rough | 447 | 380 | 31 | 31-84 | 830-2800 | |||

PYH Cone Crusher B2638 | coarse | 530 | 450 | 44 | 44-84 | 970-2800 | |||

Note: The above parameter table is for reference only.

The actual production capacity are subject to the type of material and production conditions.

Working Principle of PYH Multi-cylinder Hydraulic Cone Crusher

1. Hydraulic system provides power: The hydraulic system drives the transmission device through the hydraulic motor to drive the cone to swing.

2. Material feeding: The material to be crushed enters the crushing chamber through the feeding device.

3. Cone swing: The hydraulic system controls the cone swing by adjusting the speed and direction of the hydraulic motor.

4. Material crushing: Due to the swing of the cone, the material is constantly squeezed and impacted, and gradually crushed into smaller particles.

5. Discharge and classification: The crushed material is discharged from the outside of the machine through the discharge port and classified as needed.

Application scenarios of PYH Multi-cylinder Hydraulic Cone Crusher

PYH multi-cylinder hydraulic cone crusher is widely used in stone production, mining crushing, construction, road construction, chemical industry, metallurgy and silicate industries. With its excellent crushing efficiency and product quality, it has become an ideal equipment for producing high-quality stone, machine-made sand and processing medium-hardness ores and rocks. Multi Cylinder Cone Crusher is also suitable for mobile crushing stations, providing flexible on-site crushing solutions.

Our Service of PYH Cone Crusher (PYH Multi Cylinder Hydraulic Cone Crusher)

1. Customized Sizing Service of PYH Cone Crusher (PYH Multi Cylinder Hydraulic Cone Crusher)

Targeting the production characteristics and actual needs of different industries, we assemble a professional technical team to conduct one-on-one consultations. By in-depth analyzing key factors such as capacity goals, material properties, and site conditions, we precisely match the optimal equipment configuration to avoid capacity waste or inadequate adaptation, maximizing return on investment (ROI).

2. Efficient Logistics & Delivery of PYH Cone Crusher (PYH Multi Cylinder Hydraulic Cone Crusher)

FOB (Free On Board) is our preferred logistics term. We collaborate with high-quality logistics partners to coordinate the entire process, including equipment packaging, port loading, and compliant customs clearance. This ensures the equipment is delivered to the de. ignated destination on time and safely, shortening the production launch cycle.

3. Personalized Upgrade Solutions of PYH Cone Crusher (PYH Multi Cylinder Hydraulic Cone Crusher)

Addressing the needs of capacity expansion and energy-saving transformation for existing production lines, we provide equipment upgrade and technical optimization plans. These solutions help enhance production capacity, reduce energy consumption, and PYH Cone Crusher (Multi Cylinder Cone Crusher) flexibly adapt to industry development and Multi Cylinder Cone Crusher changes in market demand.

Our Company

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+ m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mills, heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.