Introduction to Equipment Configuration and Capacity of Granite Crushing Production Line

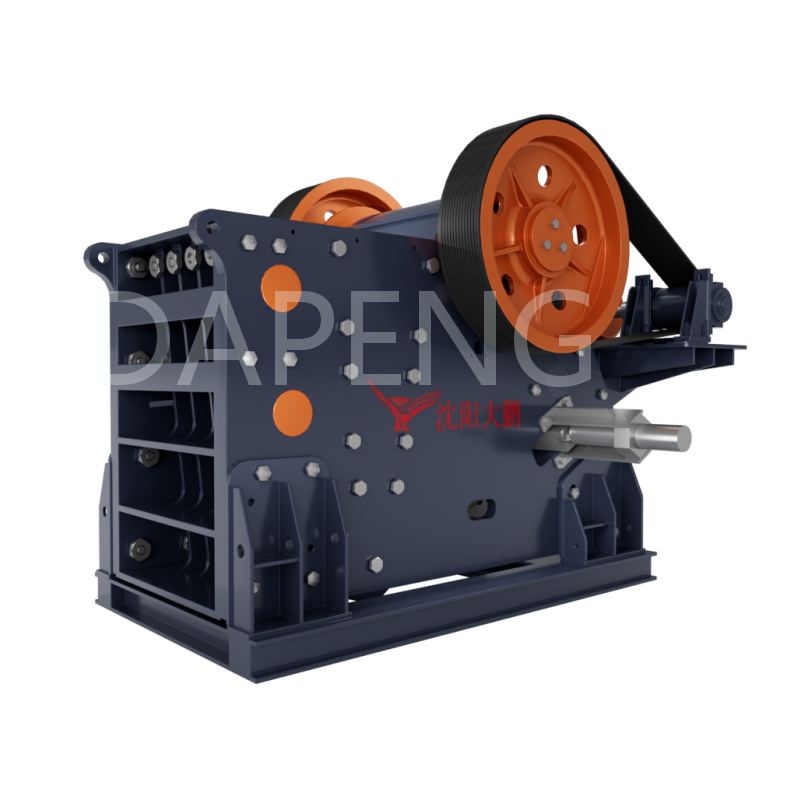

In the field of modern ore processing, there is an efficient crushing production line specifically designed for processing granite. Central to this production line are multiple jaw crushers, and these jaw crushers are the absolute workhorses driving its entire operation. This production line, being equipped with a series of well - configured jaw crushers that are strategically placed, is highly respected in the industry for jaw crusher's strong production capacity and precise control of finished product particle size.

The jaw crushers in this line play an irreplaceable and crucial role right from the very beginning. Each jaw crusher, with its robust construction, is engineered to break down large chunks of granite with remarkable efficiency. For instance, during the initial stage of processing, this stage heavily, and I mean heavily, relies on the powerful bite of the jaw crushers. These jaw crushers are the ones that initiate the all - important reduction of granite boulders into smaller, more manageable pieces. Once the jaw crushers have done their initial job, these smaller pieces are then passed on to be further processed by other crushers in the line. But it all starts with the reliable and powerful performance of these jaw crushers, which set the tone for the entire production process.

The front end of the production line prominently features two PEV1216 jaw crushers. These PEV1216 jaw crushers, as the primary crushing equipment, play an absolutely crucial and irreplaceable role on the production line. The PEV1216 jaw crusher, with its imposing structure, has a huge crushing chamber that is specifically engineered to easily accommodate large granite raw materials.

The power and efficiency of the PEV1216 jaw crusher are truly remarkable. The powerful crushing capacity of the PEV1216 jaw crusher stems from its unique jaw plate design and a supremely powerful power system. This unique combination allows the PEV1216 jaw crusher to perform preliminary coarse crushing treatment on granite raw materials with outstanding effectiveness.

During the working process of the PEV1216 jaw crusher, once the granite raw material is sent into the crushing chamber, the movable jaw plate of the PEV1216 jaw crusher periodically approaches and moves away from the fixed jaw plate under the strong driving force provided by its advanced power system. This action of the PEV1216 jaw crusher's jaw plates exerts an enormous compression and crushing force on the granite.

The PEV1216 jaw crusher's efficient crushing method is a key factor in the production line. Through this well - designed and efficient crushing process of the PEV1216 jaw crusher, the originally larger granite blocks are gradually broken into relatively smaller blocks. These smaller blocks, produced by the PEV1216 jaw crusher, provide a perfectly suitable material foundation for the subsequent fine crushing process on the production line. Every movement and operation of the PEV1216 jaw crusher is precisely coordinated to ensure the smooth progress of the entire production process.

After preliminary processing by the PEV1216 jaw crusher, the material is evenly transported to two DPCS660 single cylinder hydraulic cone crushers for further intermediate crushing operations. The DPCS660 single cylinder hydraulic cone crusher adopts an advanced single cylinder hydraulic structure and has multiple advantages. Its unique hydraulic adjustment device can conveniently and quickly adjust the size of the discharge port, thereby accurately controlling the discharge particle size. During the crushing process, the material is strongly impacted, compressed, and bent by the high-speed rotating single- cylinder's crushing cone inside the crushing chamber, resulting in further crushing and refinement of the material. This efficient crushing method not only ensures the crushing effect, but also effectively improves production efficiency. At the same time, the design of single cylinder hydraulic makes the equipment structure simple, easy to maintain, reduces the hidden dangers caused by complex structures, and ensures the stable operation of the equipment.

In order to further improve production capacity and meet the needs of different specifications of finished products, the production line is also equipped with 6 DPCH660 single cylinder hydraulic cone crushers. These single cylinder cone crushers, specifically the DPCH660 single cylinder hydraulic cone crushers, are crucial components of the production line. When combined with the DPCS660 single cylinder hydraulic cone crusher model, they form an extremely powerful medium - to - fine crushing capacity.

The single cylinder cone crushers, such as the DPCH660 and DPCS660 models, operate at a higher production speed compared to some other crushers. They are responsible for performing more detailed crushing treatment on the material discharged from the DPCS660 single cylinder hydraulic cone crusher. Each cone crusher in this setup plays a significant role in the overall process.

During the crushing process, the material passes through multiple crushing areas where it is repeatedly subjected to the action of crushing cones within these single cylinder cone crushers. The DPCH660 and DPCS660 single cylinder cone crushers work in harmony, constantly crushing and grinding the material until it meets the required particle size requirements.

Due to the large - scale configuration of these single cylinder cone crushers, with 6 DPCH660 single cylinder hydraulic cone crushers and the complementary DPCS660 single cylinder hydraulic cone crusher model, on the production line, the entire production process can be efficiently carried out. These single cylinder cone crushers, each a powerhouse in its own right, from the 6 robust DPCH660s to the well - matched DPCS660, are fundamental to the seamless operation. Their extensive use on the production line significantly improves the overall production capacity. The cone crushers, including the DPCH660 and DPCS660 models, ensure that large volumes of materials can be processed with precision to meet the diverse needs of different finished product specifications. Starting with the initial medium - crushing stage where the DPCS660 cone crusher first breaks down the materials, and then moving on to the final fine - crushing by the DPCH660 cone crushers, each cone crusher plays a crucial role in this sequential process. Each cone crusher, whether it's one of the 6 DPCH660s or the DPCS660, contributes to the seamless flow of the production, from the initial medium - crushing stage to the final fine - crushing. Their reliable performance makes these cone crushers, the DPCH660s and DPCS660, indispensable for the production line's high - performance operation. Without the continuous and effective work of these single cylinder cone crushers, efficiently processing materials to meet the strict standards of various finished product specifications would be an uphill battle. The single cylinder cone crushers' capacity to endure heavy - duty usage and execute precise crushing operations repeatedly is what makes the production line so efficient.

In terms of finished products, this production line can produce four different sizes of sand and gravel aggregates, namely 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm. These four different specifications of finished products have wide applications in various fields such as construction, roads, and water conservancy. 0-5mm fine sand can be used as fine aggregate for concrete, filling small gaps in the concrete and improving its density and strength; 5-10mm medium sand plays an important role in mortar production and can provide good bonding performance; 10-20 millimeters of coarse sand is usually used in building structures that require high strength as a skeleton support; Small stones of 20-31.5 millimeters are important foundation materials in road paving and hydraulic engineering, providing a solid foundation for engineering structures.

By reasonably combining and optimizing the configuration of different types of crushers, the granite crushing production line has achieved a high yield of 2000 tons per hour, which can stably produce high-quality sand and gravel aggregates that meet different engineering needs, providing strong support for the development of related industries.