- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

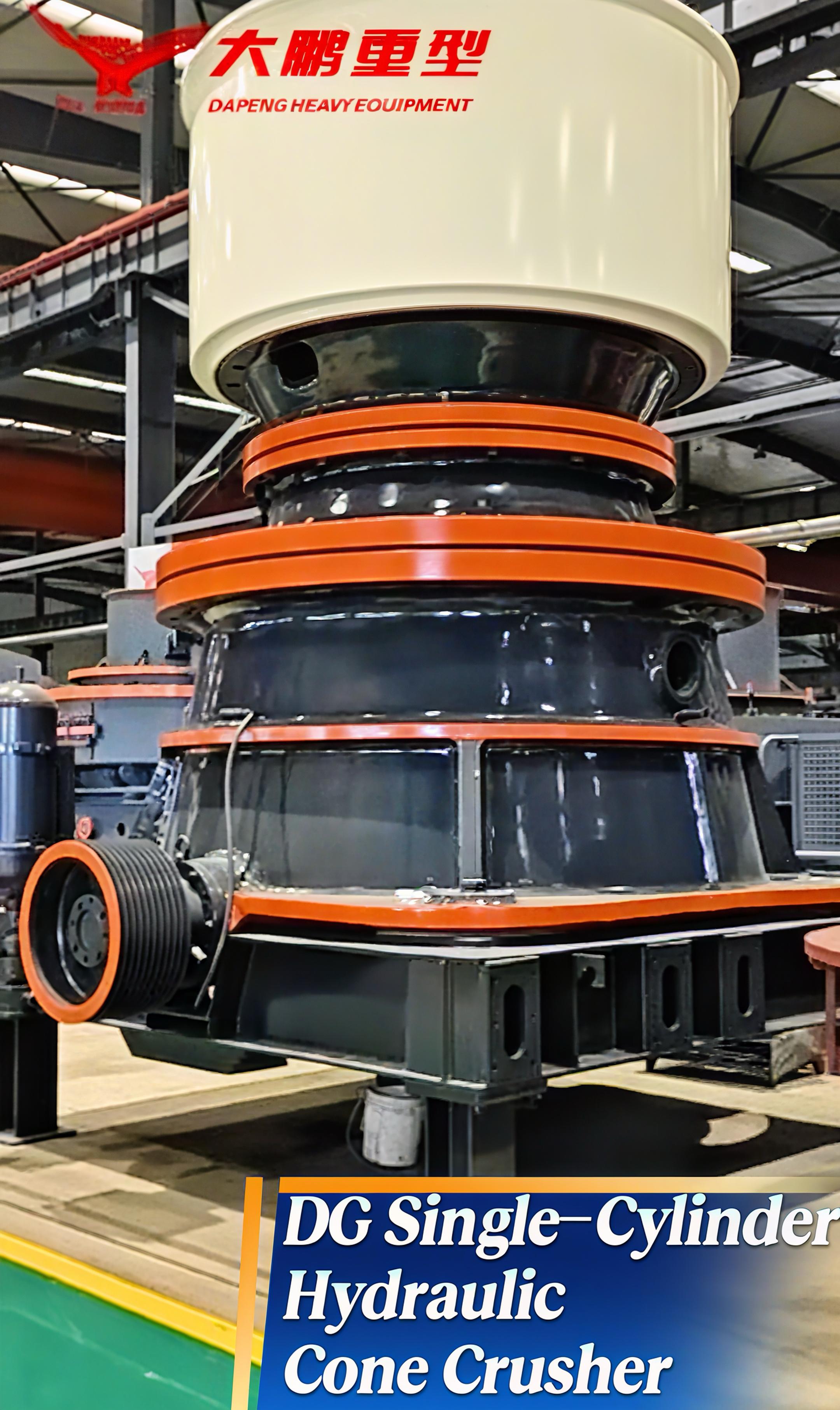

Introduction of DG Single-Cylinder Hydraulic Cone Crusher

Integrating world-leading crushing technologies, the DG Single-Cylinder Hydraulic Cone Crusher is custom-built for large and medium-scale sand, gravel, and ore processing projects. Engineered as a flexible crushing solution for secondary, tertiary, and quaternary stages of ore and rock reduction, DG Cone Crusher achieves high-efficiency material processing through the eccentric swing motion of DG Cone Crusher's mantle and concave. The equipment follows a streamlined operational flow: raw materials are fed via the top hopper, compressed and crushed between the mantle and concave, then discharged through the lower frame and collected by the discharge hopper. DG Cone Crusher is highly acclaimed for DG Cone Crusher's exceptional production capacity, low running costs, compact layout, intuitive operation, easy maintenance, wide application scope, and superior working efficiency.

Diagram

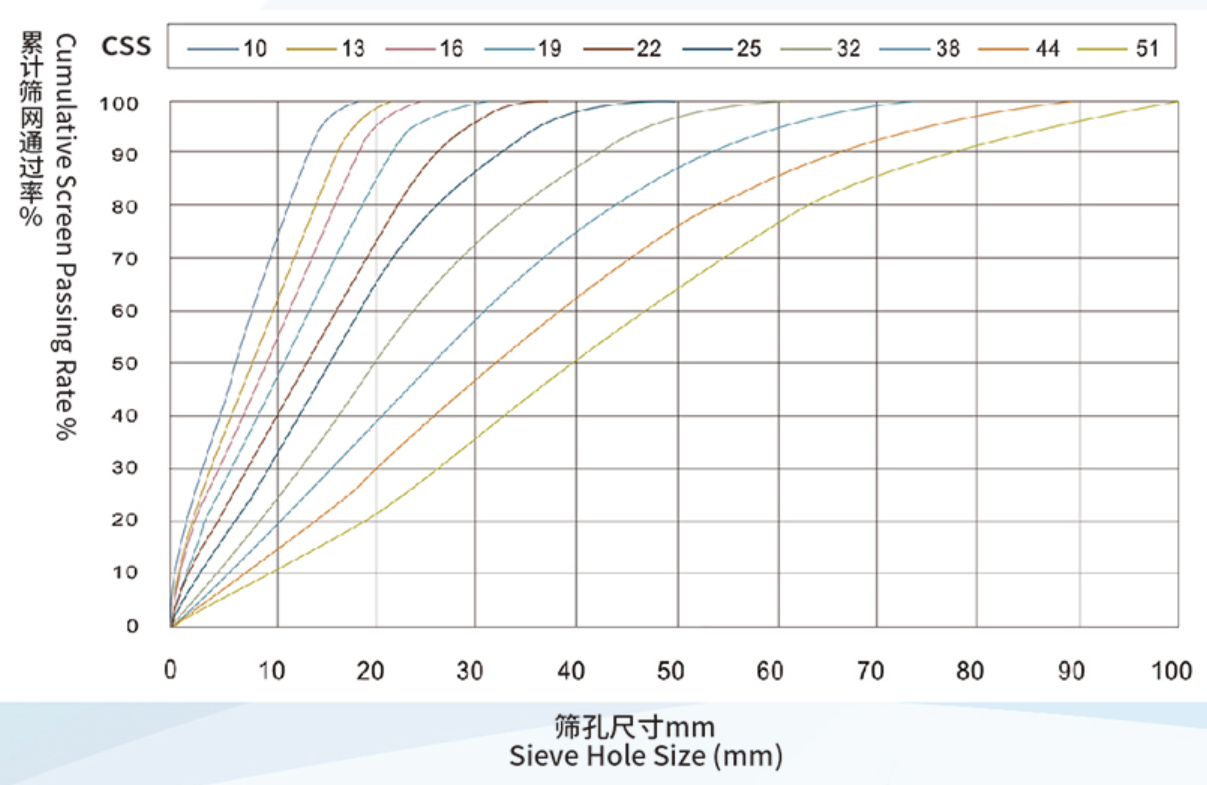

Technical Parameters

Key Features of DG Single-Cylinder Hydraulic Cone Crusher

Key Features of DG Single-Cylinder Hydraulic Cone Crusher

1. Comprehensively Optimized Structure

Fitted with a large-diameter high-strength main shaft and a heavy-duty frame, the crusher delivers enhanced structural robustness and long-term operational reliability, even under heavy-load crushing conditions.

2. Rolling Bearings Replace Traditional Bronze Bushings

By adopting heavy-duty rolling bearings instead of conventional bronze bushings, the equipment effectively reduces friction coefficient and increases main shaft swing frequency, leading to higher production output and more uniform particle shape of finished products.

3. High-Efficiency Spiral Bevel Gear System

The integrated spiral bevel gear configuration ensures high transmission efficiency, strong load-bearing capacity, and stable operation. This design also contributes to a compact structure, excellent wear resistance, extended service life, and low operational noise levels.

4. Advanced Hydraulic Control System

The upgraded hydraulic system streamlines both operation and maintenance procedures, while providing reliable overload protection to shield the equipment from unexpected damage during operation.

5. Simplified Design for Hassle-Free Operation & Maintenance

The optimized structural layout enhances operational convenience, significantly cutting down maintenance time for operators and boosting the overall production efficiency of the processing line.

6. Cutting-Edge Automated Control Technology

Equipped with a state-of-the-art automated control system, the crusher maintains maximum crushing efficiency within a safe operating range, while consistently elevating the quality of processed materials.

7. Laminated Crushing Technology for Superior Particle Shape

Leveraging the "laminated crushing" principle, combined with adjustable working parameters (rotating speed, steep cavity angle, and hyperbolic crushing cavity), DG Cone Crusher produces uniformly graded, high-quality aggregates with ideal particle shape.

8. Split-Type Upper Frame for Cost-Effective Maintenance

The upper frame is divided into two independent vertical components: the boom and mantle carrier. If wear or damage occurs, these parts can be disassembled separately, enabling quick maintenance and reducing overall operational costs.

FAQ of DG Cone Crusher

1. What applications is the DG Single-Cylinder Hydraulic Cone Crusher suitable for?

DG Cone Crusher is widely used in large and medium-sized sand, gravel, and ore processing industries, serving as secondary, tertiary, and quaternary crushing equipment for various ores and rocks.

2. How does the laminated crushing principle improve product quality?

By applying the laminated crushing principle, materials are crushed through mutual extrusion and grinding between particles, rather than just by the impact of the mantle and concave. Combined with adjustable speed, cavity angle, and hyperbolic crushing cavity, DG Cone Crusher ensures a more uniform particle size distribution and perfect particle shape of the final product.

3. What advantages does the replacement of bronze bushings with rolling bearings bring?

This replacement reduces the friction coefficient of the main shaft system, increases the swing frequency of the main shaft, effectively improves the production output of DG Cone Crusher, and optimizes the particle shape of the crushed materials. At the same time, rolling bearings have longer service life and lower maintenance frequency.

4. How does the hydraulic control system protect DG Cone Crusher from overload?

The advanced hydraulic control system monitors the load of the crusher in real time. When DG Cone Crusher encounters non-crushable foreign objects or excessive load, the system will automatically trigger the overload protection mechanism, such as adjusting the cavity clearance or stopping the machine temporarily, to avoid damage to key components.

5. Is the crusher easy to maintain?

Yes. The upper frame is designed as a split structure, and the boom and mantle carrier can be disassembled vertically separately, which greatly simplifies the maintenance process and reduces maintenance time and costs. In addition, the overall structure is compact and the operation interface is user-friendly, which is convenient for daily inspection and maintenance.

Our Service of DG Cone Crusher

1. Customized Industry Solutions & Model Selection of DG Cone Crusher

Our professional technical team conducts in-depth communication with clients to understand their industry attributes (e.g., sand and gravel production, ore processing) and specific production needs, including target crushing stages (secondary/tertiary/quaternary), material types, and finished product quality standards. Based on these insights, we recommend the most suitable DG Single-Cylinder Hydraulic Cone Crusher model and configuration, and provide tailored suggestions for production line integration to optimize overall crushing efficiency.

2. Production Progress Tracking & Strict Quality Control of DG Cone Crusher

After order confirmation, we regularly send clients detailed production progress reports, covering the manufacturing status of core components such as the main shaft, mantle, concave, and hydraulic control system. Every unit undergoes strict multi-stage quality inspections during the production process to ensure all performance indicators meet specified standards before delivery.

3. Logistics & Packaging Service (FOB as Priority Option) of DG Cone Crusher

We prioritize FOB (Free On Board) terms for logistics arrangements, cooperating with reputable international logistics providers to offer flexible and diversified transportation solutions. DG Cone Crusher is professionally packaged with high-quality shock-proof and wear-resistant materials to prevent transit damage. We also provide real-time logistics tracking and advance arrival notifications to ensure clients receive goods at the designated port on schedule.

4. Comprehensive Technical Documentation & 24/7 After-Sales Support of DG Cone Crusher

We provide a complete set of technical documents, including operation manuals, installation drawings, maintenance guides, and troubleshooting handbooks, which detail DG Cone Crusher's working principle, operation steps, and solutions to common problems. Our after-sales team offers round-the-clock technical consultation, and can dispatch professional engineers to clients' sites for on-site installation, commissioning, and operator training, ensuring the DG Single-Cylinder Hydraulic Cone Crusher runs stably and efficiently.