- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

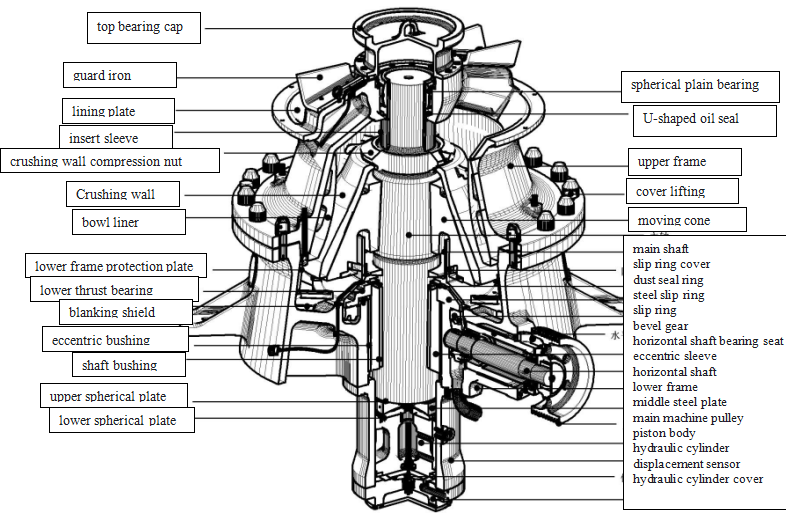

Diagram of DP Single Cylinder Hydraulic Cone Crusher (DP Cone Crusher)

Working principle of DP Single Cylinder Hydraulic Cone Crusher (DP Cone Crusher)

1. Power transmission and swing: The motor transmits power to the eccentric sleeve through the coupling or V-belt, transmission shaft and bevel gear, so that the crushing cone swings around a fixed point.

2. Crushing process: The crushing wall of the crushing cone sometimes approaches and sometimes leaves the surface of the mortar wall fixed on the adjustment sleeve, and the material is crushed by continuous squeezing, impact and bending in the crushing chamber.

3. Ore discharge and automatic adjustment:The crushed ore is discharged from the crushing chamber from the discharge port by its own weight. By adjusting the hydraulic cylinder at the bottom of the moving cone, the moving cone can be moved up and down, thereby controlling the size of the discharge port and adjusting the product particle size.

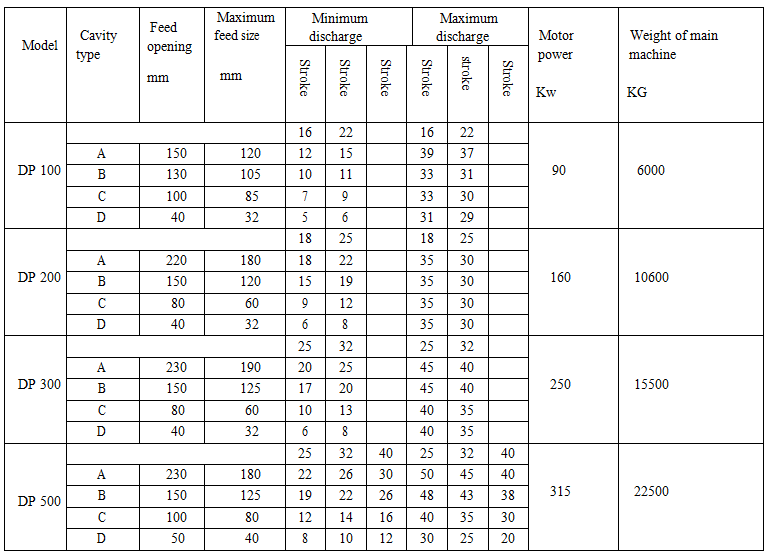

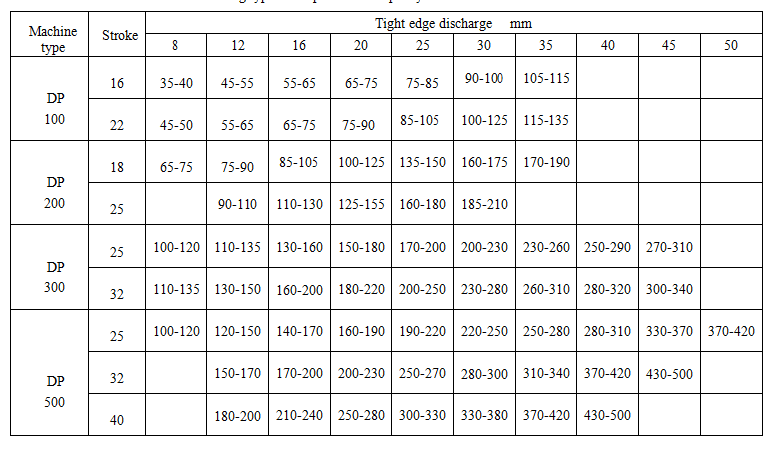

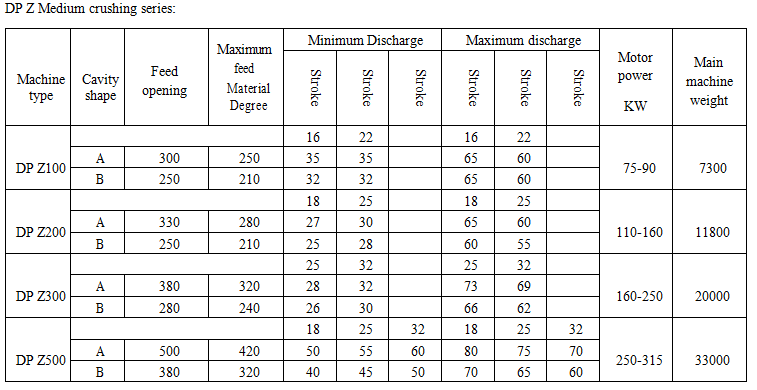

Main Technical Parameters of DP Single Cylinder Hydraulic Cone Crusher (DP Cone Crusher)

Introduction of DP Single Cylinder Hydraulic Cone Crusher (DP Cone Crusher)

DP single-cylinder hydraulic cone crusher is a high-efficiency, multi-field applicable crushing equipment. It is widely used in mining, building materials, metallurgy and other industries for its excellent crushing capacity, particle shape control, automatic overload protection, hydraulic adjustment function and easy maintenance. It can handle medium-hard materials including iron ore and granite, and realize medium and fine crushing operations. It occupies an important position in the crushing field with its excellent performance and reliability.

Performance Features of DP Single Cylinder Hydraulic Cone Crusher (DP Cone Crusher)

1. High crushing efficiency: With a double-end supported main shaft (capable of withstanding large crushing forces and strokes) and a specialized crushing cavity design, it delivers superior efficiency. Compared to old-style spring cone crushers with the same moving cone large-end diameter, output is 35%-60% higher.

2. Excellent product particle shape: Unique cavity design and lamination crushing principle significantly increase cubic particle proportion, reduce flaky/needle-shaped particles, and ensure uniform particle size distribution—meeting diverse user requirements.

3. High automation level: A single hydraulic cylinder lifts/lowers the moving cone, enabling automatic discharge opening adjustment and real-time size display during operation. Optional electronic intelligent control system supports advanced process control and optimization (e.g., automatic adjustment for single crushers, centralized control of multiple units via control room, dynamic load-based adjustment of discharge opening/power/pressure, and real-time display of operating parameters including liner wear).

4. Easy maintenance: The upper frame can be lifted by removing just a few bolts; maintenance is accessible from the top with minimal parts required. Spare parts inventory is low, reducing costs—e.g., fixed-cone liner removal and tooth gap adjustment only need a few bolts loosened, saving time and labor.

5. Reliable overload protection: Adjustable accumulator pressure provides sensitive overload and tramp iron protection. When uncrushable foreign objects (e.g., iron blocks) are encountered, the hydraulic cylinder automatically lifts the moving cone to allow passage, preventing equipment damage and ensuring safe operation.

Our Service of DP Single Cylinder Hydraulic Cone Crusher (DP Cone Crusher)

1. Customized Consultation of DP Cone Crusher

Needs Assessment: Our technical team will conduct in-depth communication with you to understand your project requirements, including daily output expectations, material characteristics (hardness, particle size of iron ore, granite, limestone, etc.), and crushing stage (secondary or tertiary crushing), so as to recommend the most suitable DP series model and configuration.

Solution Design of DP Cone Crusher: For large-scale mining or aggregate production lines, we can provide matching suggestions for the integration of the DP crusher with your existing equipment (feeders, conveyors, screening equipment), ensuring seamless connection and optimized overall production efficiency.

2. Professional Support of DP Cone Crusher

Production Progress Tracking: After order confirmation, we will regularly update you on the manufacturing progress of the equipment, including the production status of core components and the estimated delivery time, keeping you fully informed.

3. Logistics & Packaging Guarantee of DP Cone Crusher

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) to ensure it is delivered to your designated site intact and on time.

4. Technical Documentation & Guidance

We provide comprehensive technical documents, including operation manuals, installation diagrams, and troubleshooting guides, which detail the equipment's working principle, operation steps, and common problem solutions for your reference.

FAQ of DP Single Cylinder Hydraulic Cone Crusher (DP Cone Crusher)

Q1: Can the DP single cylinder hydraulic cone crusher (DP Cone Crusher) be adapted to our existing production line?

A1: Yes. The DP series crushers feature strong compatibility. Our technical team will collect parameters of your existing equipment (e.g., feeder output, conveyor belt width, vibrating screen specifications) and adjust the DP cone crusher's relevant configurations (feed port size, installation dimensions) to ensure perfect matching. We will provide professional integration suggestions to avoid material blockage or efficiency loss caused by mismatched equipment.

Q2: What types of materials can the DP single cylinder hydraulic cone crusher (DP Cone Crusher) handle? What is the applicable crushing stage?

A2: The DP cone crusher is designed for medium-hard and above materials, including iron ore, granite, basalt, limestone, and other non-metallic minerals. It is mainly used for secondary and tertiary crushing operations, and can produce high-quality cubic finished products that meet the requirements of construction, mining, and metallurgy industries.

Q3: How to adjust the discharge port size of the DP single cylinder hydraulic cone crusher (DP Cone Crusher)? Is it convenient to operate?

A3: The discharge port is adjusted through the bottom hydraulic cylinder, which is highly automated and easy to operate. You can directly adjust the lifting of the moving cone via the intelligent control system to change the discharge port size, and the DP Cone Crusher system will automatically display the current size in real time. For on-site operation, only simple parameter setting is required, no complex disassembly is needed, saving time and labor.

Q4: What should I do if the crusher encounters unbreakable foreign objects (such as iron blocks) during operation?

A4: The DP cone crusher is equipped with a sensitive hydraulic overload protection system. When foreign objects enter the crushing cavity, the hydraulic cylinder will automatically lift the moving cone to allow the foreign objects to pass through smoothly, avoiding damage to core components (spindle, crushing wall). After the foreign objects are discharged, the equipment can quickly resume normal operation without manual intervention, ensuring safe and continuous production.