- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

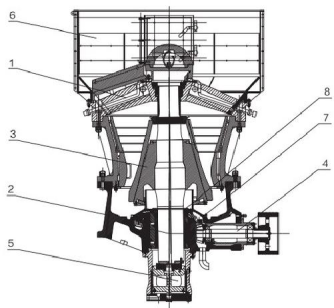

Diagram of DPCS Single Cylinder Hydraulic Cone Crusher (DPCS Crusher)

1. Upper frame 2. Lower frame 3. Broken cone

4. Driving part 5. Hydraulic cylinder 6. Feeding device

7. Eccentric sleeve 8. Sealing part

Introduction of DPCS Single Cylinder Hydraulic Cone Crusher (DPCS Crusher)

DPCS Single Cylinder Hydraulic Cone Crusher (DPCS Cone Crusher) is a high performance crushing equipment, designed to meet the modern mining industry's demand for high efficiency and high reliability. The DPCS single cylinder con crusher (DPCS Cone Crusher) is famous for its single cylinder hydraulic structure of DPCS Crusher, which can provide stable crushing performance and excellent product particle shape. DPCS Single Cylinder Cone Crusher (DPCS Crusher) adopts an advanced hydraulic adjustment system, making the adjustment of the discharge port and overload protection operation easier and safer.

Technical Parameters of DPCS Single Cylinder Hydraulic Cone Crusher (DPCS Crusher)

Model | Maximum Feeding Particle Size (mm) |

Adjustment range of Discharge port | Motor Power (KW) | Production Capacity (t/h) | Equipment Weight (t) |

DPCS 430 | 360 | 19-51 | 132 | 91-344 | 12 |

DPCS 440 | 450 | 25-34 | 250 | 267-601 | 20 |

DPCS Single Cylinder Cone Crusher | Model | Cavity Type | DPCS Crusher Standard Production Capacity (t/h) under the Tight Side Discharge Port css (mm) | |||||||||

41 | 44 | 48 | 51 | 54 | 60 | 64 | 70 | 76 | 83 | |||

DPCS 430 | EC | 174-327 | 183-344 | 196-306 | 205-256 | 214 | ||||||

C | 161-301 | 169-264 | 108 | |||||||||

MC | 147-275 | 154-241 | 165 | |||||||||

DPCS 440 | EC | 298-446 | 313-563 | 334-601 | 349-524 | 365-456 | ||||||

C | 284-511 | 298-448 | 318-398 | 333 | ||||||||

MC | 270-486 | 284-426 | 303-378 | 317 | ||||||||

DPCS 660 | EC | 349 | 368-460 | 392-588 | 410-718 | 428-856 | 465-929 | 489-978 | 525-1050 | 562-983 | 604 | |

C | 336-420 | 353-618 | 376-753 | 394-788 | 411-823 | 446-892 | 489-822 | 504-631 | ||||

Note: The above parameter table is for reference only.

The actual production capacity is determined by the type of materials and production conditions.

Advantages of DPCS Single Cylinder Hydraulic Cone Crusher (DPCS Cone Crusher)

1. High & stable output: Small moving cone top angle accelerates material falling; constant cavity system maintains liner shape for steady feeding/capacity.

2. Simple structure & reliable performance: Optimized mechanical system with low failure rate, stable transmission and operation.

3. Easy cavity cleaning & maintenance: Integrated hydraulic adjustment/protection; maintenance workable on-frame, quick liner replacement saves downtime.

4. Wide application & excellent particle shape: Multiple cavity types, adjustable stroke/frequency, easy discharge port adjustment; lamination crushing ensures good particle shape.

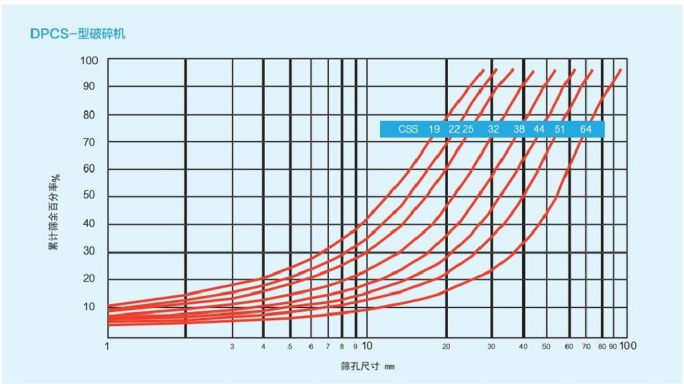

Product granularity curve of DPCS Single Cylinder Hydraulic Cone Crusher (DPCS cone crusher)

Working principle of DPCS Single Cylinder Hydraulic Cone Crusher (DPCS Crusher)

DPCS single cylinder cone crusher (DPCS cone crusher) realizes the rotation of the moving cone through the eccentric sleeve driven by DPCS Crusher's motor, squeezes the material for lamination crushing, and produces uniform cubic particles. The hydraulic system of DPCS Single Cylinder Cone Crusher (DPCS Crusher) automatically adjusts the discharge port when encountering unbreakable objects or overload, protects DPCS Crusher and discharges foreign matter. At the same time, the lubrication system of DPCS Crusher (DPCS Cone Crusher) ensures the long-term operation of key components.

Application scenarior of DPCS Cylinder Hydraulic Cone Crusher (DPCS Cone Crusher)

1. Mining crushing: Medium and fine crushing of metal/non-metallic ores.

2. Infrastructure construction: Road, railway, and water conservancy projects (aggregate production).

3. Construction industry: Production of standard stones, construction aggregates, and recycled construction waste.

4. Industrial processing: Metallurgical, chemical industries (crushing high-hardness, high-abrasion raw materials).

5. Sand and gravel production: Economical crushing of raw materials for sand and gravel aggregates.

FAQ of DPCS Crusher (DPCS Cone Crusher)

1. What are the core professional advantages of this DPCS single-cylinder cone crusher (DPCS Crusher)?

Focused on secondary/tertiary crushing, the DPCS Cone Crusher (DPCS Crusher) features a single-cylinder hydraulic precision control system, delivering excellent crushing ratio and uniform output size. DPCS Crusher's integrated design boosts operational stability, with high-quality wear-resistant parts for long durability. DPCS Crusher's hydraulic cavity cleaning and automatic discharge reduce downtime, suitable for large-scale continuous production with high efficiency and low energy consumption.

2. How to accurately select the model to match specific production needs?

Our technical team provides one-on-one solutions based on your industry, capacity target, raw material strength, feed/output size and site conditions, combined with the DPCS single-cylinder cone crusher's (DPCS Crusher) unique crushing features, ensuring optimal production efficiency matching.

3. What are DPCS Crusher logistics, loading and delivery terms?

FOB is preferred, we handle standardized packaging, port loading and compliant customs clearance for safe efficient delivery. Custom compliant logistics solutions and full shipping documents are available on demand.

Our Service of DPCS Crusher

Customized Sizing & Solution Design of DPCS Crusher

For production processes and crushing needs of different industries, a professional technical team is established for in-depth communication. By accurately analyzing key factors such as Single Cylinder Cone Crusher's (DPCS Cone Crusher) capacity requirements, material characteristics and site constraints, combined with the core advantages of Single Cylinder Cone Crusher (DPCS Cone Crusher) in secondary and tertiary crushing, exclusive crushing solutions are designed and optimal model configurations are matched to avoid capacity waste or insufficient adaptation and help achieve Single Cylinder Cone Crusher's (DPCS Cone Crusher) efficient production.

Efficient Logistics & Delivery Support of DPCS Crusher

With FOB as the standard logistics mode, we cooperate with high-quality global logistics partners to coordinate all links including Single Cylinder Cone Crusher (DPCS Cone Crusher) factory inspection, professional packaging, port loading, customs declaration and clearance. Provide full-process logistics tracking services to ensure that Single Cylinder Cone Crusher (DPCS Cone Crusher) is safely delivered to the designated destination as scheduled and shorten the production preparation cycle. Customized logistics solutions can be negotiated according to project needs to adapt to transportation requirements in different regions.

Certificates