- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

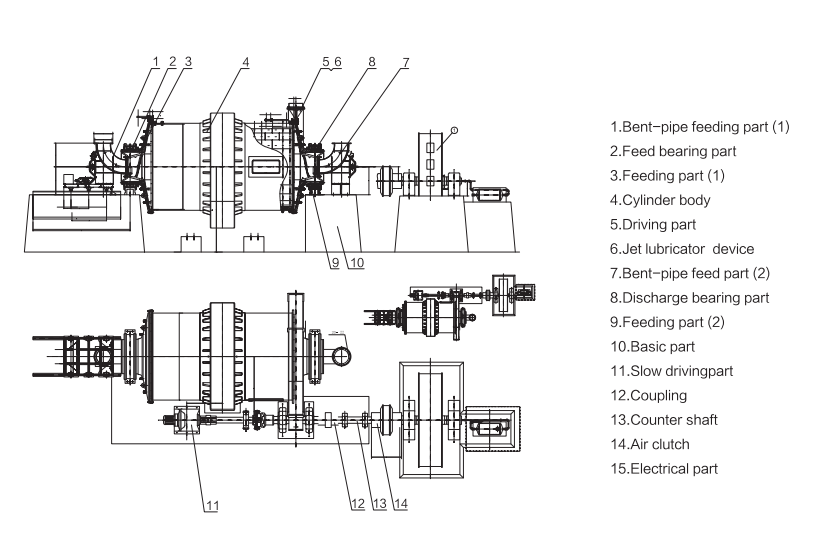

Diagram of DPMB Rod Mill (grinding equipment for mining)

Introduction of DPMB Rod Mill (grinding equipment for mining)

DPMB Rod Mill (grinding equipment for mining) is a highly efficient and energy-saving sand-making equipment, which can save 50% energy compared with traditional sand-making machines. After DPMB Rod Mill (grinding equipment for mining) makes sand, the particle size is relatively uniform, with less over-crushed particles, and the edges and corners are basically flattened to an elliptical shape. The cylinder rotates at a certain speed, and the DPMB Rod Mill's grinding body rises to a certain height under the action of friction and centrifugal force and is thrown down, so that the material is impacted and ground to achieve the purpose of sand making. DPMB Rod Mill (grinding equipment for mining) is mainly suitable for processing and crushing various hard and brittle materials such as steel sand, slag powder, copper ore, iron ore, gold ore, feldspar, quartz, river pebbles, concrete aggregate, asphalt, aggregate, etc.

Technical Parameter of DPMB Rod Mill (grinding equipment for mining)

| DPBM Rod Mill Technical Parameter | |||||

| Model | Cylinder diameter(mm) | Effective Volume(m³) | Weight(t) | Motor(kw) | Capacity(t/h) |

| DPBM 1530 | 1500 | 5 | 19.8 | 95 | 50-60 |

| DPBM 1830 | 1800 | 7.4 | 36.9 | 160 | 70-90 |

| DPBM 2130 | 2100 | 9.4 | 47.8 | 210 | 90-110 |

| DPBM 2136 | 2100 | 10.8 | 50.6 | 210 | 110-130 |

| DPBM 2436 | 2400 | 14.6 | 68.3 | 315 | 130-160 |

| DPBM 2736 | 2700 | 18.4 | 77.21 | 400 | 170-200 |

| DPBM 2745 | 2700 | 22.4 | 78.17 | 500 | 210-250 |

| DPBM 3245 | 3200 | 32.8 | 105.8 | 800 | 320-380 |

| DPBM 3254 | 3200 | 39.5 | 127.5 | 800 | 380-450 |

| DPBM 3358 | 3300 | 45.2 | 145.3 | 1000 | 440-500 |

| DPBM 3645 | 3600 | 42 | 134.2 | 1000 | 420-500 |

| DPBM 3650 | 3600 | 46.7 | 140.5 | 1000 | 450-540 |

| DPBM 3660 | 3600 | 53.7 | 152.6 | 1250 | 550-650 |

| DPBM 3858 | 3800 | 61 | 178.2 | 1250 | 600-700 |

| DPBM 4060 | 4000 | 71 | 189.5 | 1400 | 700-800 |

| DPBM 4360 | 4300 | 81.1 | 218.2 | 1600 | 800-950 |

| DPBM 4560 | 4500 | 92.1 | 233.5 | 1800 | 900-1100 |

| Note: The above parameter table is for reference only, and the actual production capacity depends on the material type and production conditions | |||||

Performance characteristics of DPMB Rod Mill (grinding equipment for mining)

1. Superior Particle Size Control

Operating on the linear contact principle of steel rods, DPMB Rod Mill (grinding equipment for mining) ensures uniform stress distribution on materials inside the cylinder. This delivers consistent finished product particle size and effectively prevents excessive crushing, making it ideal for production processes with strict particle size requirements.

2. Powerful & Versatile Processing Capacity

DPMB Rod Mill (grinding equipment for mining) has excellent material compatibility, efficiently handling both high-hardness ores and soft-textured materials. It shows outstanding capacity when processing medium-hardness materials, fully meeting the demands of large-scale, high-volume production of Rod mill for mining.

3. Low Wear & Maintenance Costs of Rod mill for mining

Compared with ball mill, DPMB Rod Mill's steel rods wear evenly, significantly extending the service cycle. This reduces steel rod replacement frequency and cuts down on both time and capital costs related to Rod mill for mining maintenance, achieving higher cost-efficiency.

4. Strong Adaptability

Flexible adjustments to steel rod specifications, filling ratio, and cylinder rotation speed allow DPMB Rod Mill (grinding equipment for mining) to quickly adapt to different material characteristics and meet diverse particle size requirements. DPMB Rod Mill (grinding equipment for mining) operates stably in complex scenarios, serving multiple industries including mining and industrial material processing.

5. Easy Operation & Maintenance

DPMB Rod Mill's simple structural design enables straightforward operation steps and easy daily maintenance. Even operators with limited technical expertise can master DPMB Rod Mill's use quickly, minimizing Rod mill for mining downtime and ensuring continuous, stable operation for both large and small-scale setups.

FAQ of DPMB Rod Mill (grinding equipment for mining)

1. What advantages does the DPMB Rod Mill have in particle size control?

DPMB Rod Mill adopts the linear contact principle of steel rods, enabling uniform stress on materials inside the cylinder. This ensures excellent consistency of finished product particle size and effectively avoids excessive crushing, making it ideal for production scenarios with strict particle size requirements.

2. What types of materials can the DPMB Rod Mill (grinding equipment for mining) process?

DPMB Rod Mill has strong adaptability and can efficiently handle both high-hardness ores and soft-textured materials, especially showing outstanding production capacity advantages when processing medium-hardness materials, which can meet the needs of large-scale high-volume processing.

3. Why is the DPMB Rod Mill (grinding equipment for mining) more cost-effective in wear?

During operation, the steel rods in the DPMB Rod Mill (grinding equipment for mining) wear evenly, which significantly extends their service life. This reduces the frequency of steel rod replacement and lowers the time and capital costs associated with Rod mill for mining maintenance.

4. How to adjust the DPMB Rod Mill to adapt to different materials and product requirements?

You can flexibly adjust the specifications of the internal steel rods, the filling ratio of the rods, and the rotation speed of the cylinder. These adjustments allow the mill (grinding equipment for mining) to quickly adapt to the characteristics of different materials and meet diverse finished product particle size requirements.

5. Is the DPMB Rod Mill (Rod mill for mining) easy to operate and maintain?

Yes. DPMB Rod Mill (Rod mill for mining) has a simple structural design, resulting in uncomplicated operation steps and straightforward daily maintenance. Even operators with limited technical experience can quickly master its use, which helps minimize downtime and ensure continuous and stable operation.

6. Can the DPMB Rod Mill (grinding equipment for mining) meet the needs of large-scale production?

Absolutely. DPMB Rod Mill (Rod mill for mining) has powerful processing capacity and excellent material compatibility, which can fully match the tight rhythm of large-scale production. DPMB Rod Mill (Rod mill for mining) is a preferred choice for industries that require high-volume material processing.

Our Service of DPMB Rod Mill (Rod mill for mining)

We focus on providing professional support throughout your procurement and Rod mill for mining commissioning process for the DPMB Rod Mill (Rod mill for mining), ensuring the Rod mill for mining perfectly matches your production needs and starts operation smoothly.

1. Pre-Sales Customized Consultation

Demand Matching & Model Selection: Our technical team will conduct in-depth communication to clarify your core requirements, including the type and hardness of materials to be ground (e.g., ore, industrial raw materials), required finished particle size, hourly output target, and site installation conditions (space for cylinder length/diameter, power supply parameters).

If you need to integrate the rod mill (Rod mill for mining) into an existing production line (such as a mineral processing line), our team will analyze the parameters of your existing feeding, conveying and discharging systems to ensure seamless connection and avoid material blockage or mismatched capacity. We will also provide targeted suggestions on steel rod specifications, filling ratio and cylinder rotation speed based on your material characteristics.

2. In-Sales Quality Control & Delivery Guarantee

Production Progress Tracking: After order confirmation, we will regularly send you production progress reports, so that you can clearly know Rod mill for mining's production schedule and estimated delivery time.

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) to ensure DPMB Rod Mill (Rod mill for mining) is delivered to your designated site intact and on time. Rod mill for mining will be professionally packaged to prevent damage during transportation.

3. Technical Guidance & Documentation Support

We provide comprehensive technical documents of Rod mill for mining, including operation manuals, installation diagrams, and troubleshooting guides, which detail the Rod mill for mining's working principle, operation steps, daily maintenance points, and common problem solutions (such as steel rod replacement, wear handling) for your reference.

Our Company

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+ m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mill (Rod mill for mining), heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.