- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

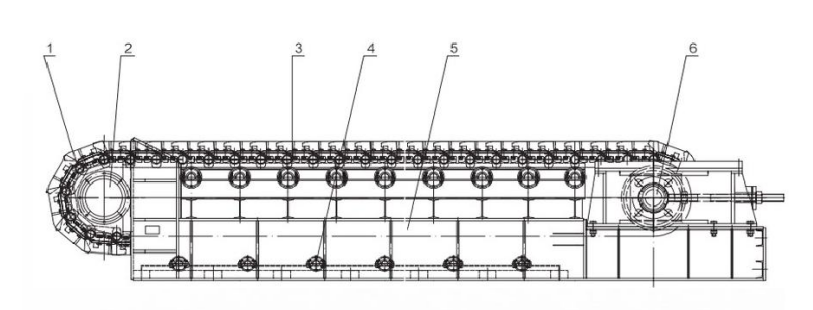

Diagram of GBZ Plate Feeder

1. Chian plate device 2. Main shaft device 3. Load bearing wheel

4. Low towing wheel 5. Frame 6. Tension device

Introduction of GBZ Heavy Plate Feeder (Heavy Apron Feeder)

GBZ Heavy Plate Feederundertakes the feeding task in industrial scenarios such as mines and metallurgy. The main body of Heavy Plate Feeder (Heavy Apron Feeder) includes a feeding plate, a chain, a driving device, a tensioning device, and a frame. Among them, the feeding plate is mostly made of high-strength wear-resistant steel and is responsible for carrying materials; the chain is made of alloy steel and is sturdy and durable.

During operation, the driving device drives the chain to rotate, and the chain pulls the feeding plate to move circularly, enabling the materials to be orderly conveyed from the feeding port to the discharging port. Heavy Plate Feeder (Heavy Apron Feeder) provides stable and uniform feeding and has a strong conveying capacity. The single feeding amount can reach thousands of tons, and the feeding particle size can exceed 1000mm.

Due to the wear-resistant design of the key components of Heavy Plate Feeder (Heavy Apron Feeder), Heavy Plate Feeder (Heavy Apron Feeder) wear resistance has been greatly improved, the failure rate has been reduced, and the service life of Heavy Apron Feeder has been extended. Moreover, Heavy Plate Feeder (Heavy Apron Feeder) can flexibly adjust the operating parameters according to the characteristics of the materials and process requirements, making Heavy Plate Feeder (Heavy Apron Feeder) adaptable to complex working conditions. In addition, with the help of the PLC control system, remote operation and automated supervision can be realized, which greatly improves the degree of production automation and reduces the labor input of GBZ apron feeder.

Technical Parameters of Heavy-type plate feeder (Heavy Apron Feeder)

| GBZ heavy plate feeder (Heavy Apron Feeder) | |||||||

| Model | Width of chain Plate (mm) | Axis distance of chain plate (mm) | Motor (kw) | Maximum Feed (mm) | Capacity (m³/h) | Feeding speed (m/s) | Weight (t) |

| GBZ 80-2 | 800 | 2000 | 3 | 300 | 80-100 | 0.04-0.1 | 3.8 |

| GBZ80-10 | 800 | 10000 | 7.5 | 300 | 80-100 | 0.04-0.1 | 15 |

| GBZ80-14 | 800 | 14000 | 11 | 300 | 80-100 | 0.04-0.1 | 17 |

| GBZ100-6 | 1000 | 6000 | 11 | 500 | 100-200 | 0.04-0.1 | 14.5 |

| GBZ100-7 | 1000 | 7000 | 11 | 500 | 100-200 | 0.04-0.1 | 17 |

| GBZ100-9 | 1000 | 9000 | 15 | 500 | 100-200 | 0.04-0.1 | 19 |

| GBZ120-5 | 1200 | 5000 | 15 | 500 | 100-200 | 0.04-0.1 | 33.4 |

| GBZ120-8 | 1200 | 8000 | 22 | 500 | 100-200 | 0.04-0.1 | 41.3 |

| GBZ120-10 | 1200 | 10000 | 22 | 500 | 100-200 | 0.04-0.1 | 46.9 |

| GBZ120-12 | 1200 | 12000 | 30 | 500 | 100-200 | 0.04-0.1 | 51.8 |

| GBZ125-6 | 1250 | 6000 | 15 | 500 | 150-250 | 0.04-0.1 | 11.5 |

| GBZ125-8 | 1250 | 8000 | 15 | 500 | 150-250 | 0.04-0.1 | 13 |

| GBZ125-9 | 1250 | 9000 | 15 | 500 | 150-250 | 0.04-0.1 | 14 |

| GBZ125-12 | 1250 | 12000 | 15 | 500 | 150-250 | 0.04-0.1 | 20 |

| GBZ125-18 | 1250 | 18000 | 15 | 600 | 150-250 | 0.04-0.1 | 32 |

| GBZ140-12 | 1400 | 12000 | 22 | 800 | 200-300 | 0.04-0.1 | 32 |

| GBZ150-5 | 1500 | 5000 | 22 | 800 | 200-300 | 0.04-0.1 | 27.5 |

| GBZ150-6 | 1500 | 6000 | 22 | 800 | 200-300 | 0.04-0.1 | 31.4 |

| GBZ150-8 | 1500 | 8000 | 22 | 800 | 200-300 | 0.04-0.1 | 35.5 |

| GBZ150-10 | 1500 | 10000 | 30 | 800 | 200-300 | 0.04-0.1 | 43.65 |

| GBZ150-18 | 1500 | 18000 | 30 | 800 | 200-300 | 0.04-0.1 | 55 |

| GBZ155-18 | 1550 | 18000 | 30 | 800 | 200-300 | 0.04-0.1 | 60 |

| GBZ160-7 | 1600 | 7000 | 15 | 800 | 200-350 | 0.04-0.1 | 27 |

| GBZ160-9 | 1600 | 9000 | 18.5 | 800 | 200-350 | 0.04-0.1 | 30 |

| GBZ180-8 | 1800 | 8000 | 30 | 1000 | 300-500 | 0.04-0.08 | 50 |

| GBZ180-9 | 1800 | 9000 | 30 | 1000 | 300-500 | 0.04-0.08 | 52 |

| GBZ180-9.8 | 1800 | 9800 | 37 | 1000 | 350-500 | 0.04-0.08 | 55 |

| GBZ180-10 | 1800 | 10000 | 37 | 1000 | 350-500 | 0.04-0.08 | 55 |

| GBZ200-10 | 2000 | 10000 | 45 | 1050 | 350-800 | 0.04-0.08 | 67 |

| GBZ220-10 | 2200 | 10000 | 90 | 1100 | 350-1200 | 0.04-0.08 | 81 |

| GBZ220-12 | 2200 | 12000 | 45 | 1100 | 350-1200 | 0.04-0.08 | 89 |

| GBZ230-10 | 2300 | 10000 | 37*2 | 1150 | 360-1350 | 0.04-0.08 | 91 |

| GBZ240-4 | 2400 | 4000 | 22 | 1200 | 440-1550 | 0.04-0.08 | 44.8 |

| GBZ240-5 | 2400 | 5000 | 30 | 1200 | 440-1550 | 0.04-0.08 | 50.73 |

| GBZ240-5.6 | 2400 | 5600 | 30 | 1200 | 440-1550 | 0.04-0.08 | 52.477 |

| GBZ240-8 | 2400 | 8000 | 40 | 1200 | 440-1550 | 0.04-0.08 | 76.373 |

| GBZ240-10 | 2400 | 10000 | 45 | 1200 | 440-1550 | 0.04-0.08 | 85.331 |

| GBZ240-12 | 2400 | 12000 | 45 | 1200 | 440-1550 | 0.04-0.08 | 89.5 |

| Note: The above parameter table is for reference only, and the actual production capacity depends on the material type and production conditions | |||||||

Advantages of GBZ Heavy Plate Feeder (Apron Feeder)

1. GBZ Heavy-type Plate Feeder (Apron Feeder), an advanced Heavy Plate Feeder, requires its feeding speed to be selected within the following series of values. The deviation between the actual feeding speed and the set value for this GBZ Plate Feeder must be strictly controlled within ±10%.

2. When the GBZ Plate Feeder, specifically GBZ Heavy-type Plate Feeder (Apron Feeder), is installed in an inclined position, a braking component is equipped. This component effectively prevents the conveying chain of this Heavy Feeder from reversing, ensuring stable feeding.

3. The driving device of the GBZ Plate Feeder uses a perpendicular planetary series combined reducer for power transmission. This reducer endows the Heavy Plate Feeder with multiple advantages such as light weight, high mechanical efficiency, long service life, compact structure, and reduced space occupation.

4. The main shaft device of the GBZ Series Heavy-type Plate Feeder abandons traditional key connections and adopts a keyless smooth shaft. When connecting the main shaft to the sprocket and star wheel, the expansion sleeve connection technology simplifies installation, disassembly, and maintenance for this Heavy Feeder.

5. The chain plate device of the Plate Feeder, like the GBZ Series Heavy-type Plate Feeder (Heavy Apron Feeder), offers two structural forms: double-arc lap joint and single-arc lap joint. Both forms prevent material leakage during the operation of the GBZ Plate Feeder (Heavy Apron Feeder).

6. The tank chain is used as the transmission chain for Heavy Apron Feeder. This GBZ Heavy-type Plate Feeder (Apron Feeder) benefits from the tank chain’s high pitch accuracy, eliminating the need for lubrication. Installation and maintenance are easy, with strong interchangeability and excellent durability for this Heavy Feeder.

7. By embedding guiding idler wheels and redirecting smooth wheels on the tail shaft between the inner chain links, the GBZ Plate Feeder's unique design eliminates the risk of running off-course. This innovation makes the Heavy Feeder operate more stably.

8. The composite spring-type buffer tensioning mechanism of the GBZ Series Heavy-type Plate Feeder (Apron Feeder) buffers impact forces, reducing damage and prolonging the overall service life of this Heavy Plate Feeder.

FAQ of GBZ Heavy Apron Feeder (Apron Feeder)

Q1: How to confirm the most suitable GBZ Heavy Apron Feeder (GBZ Heavy-type plate feeder) model for my project?

A1: You only need to provide three core information: ① Maximum particle size of the material (e.g., 800mm for iron ore, 1000mm for granite); ② Expected hourly capacity (e.g., 300m³/h for limestone conveying); ③ Installation conditions (inclination angle, installation length limit). Our technical team will match the corresponding model from the parameter table.

Q2: Can the GBZ heavy apron feeder (GBZ Heavy-type plate feeder) be installed at an large inclination angle?

A2: No. Exceeding our range will lead to two major problems: ① Material sliding down during conveying, affecting the stability of uniform feeding; ② The chain plate device is prone to deviation, increasing the risk of GBZ Heavy-type plate feeder (GBZ Heavy Apron Feeder) failure.

Our Service of GBZ Heavy Apron Feeder

1. Pre-Sales Customized Consultation of GBZ Heavy-type plate feeder

Demand Deep Dive: Our technical team will conduct in-depth communication to clarify your core requirements, including material characteristics (hardness, bulk density, maximum particle size), daily output target, installation space (length, width, height limitations), and inclination angle requirements. Based on this, we recommend the most suitable GBZ model and supporting configurations.

2. Professional Support of GBZ Heavy Plate Feeder

Production Progress Tracking: After order confirmation, we will regularly update you on the manufacturing progress of the equipment, including the production status of core components and the estimated delivery time, keeping you fully informed.

3. Logistics & Packaging Guarantee of GBZ Heavy Plate Feeder (Heavy-type plate feeder)

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions of GBZ Heavy-type plate feeder (FOB, CIF, etc.) to ensure GBZ Heavy-type plate feeder (Heavy Plate Feeder) is delivered to your designated site intact and on time.

Certificates