- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

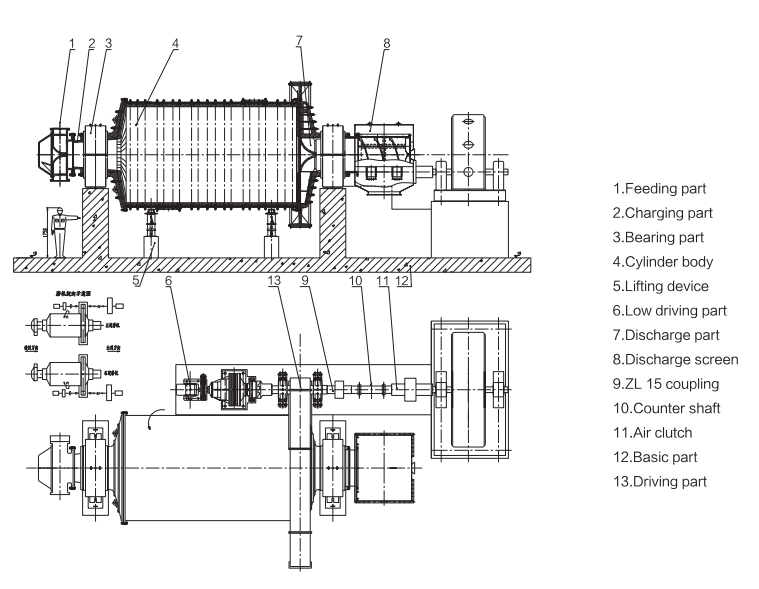

Diagram of MQS Ball Mill

Introduction of MQS Ball Mill

The MQS Ball Mill (grinding equipment) is a key equipment for crushing materials after they are crushed. MQS Ball Mill consists of main parts such as MQS Ball Mill's feeding part, discharging part, rotating part, and transmission part. These MQS Ball Mills play a crucial role in the processing line. MQS Ball Mills (grinding equipment) are widely used in various production industries including cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal beneficiation, glass, and ceramics. MQS Ball Mills are capable of grinding various ores and other grindable materials either by the dry method or the wet method. The MQS Ball Mills (grinding equipment) have proven MQS Ball Mill's (grinding equipment) significance in these industries for MQS Mill's efficient grinding performance. Different types of MQS Ball Mills (grinding equipment) can be selected according to specific production requirements, and MQS Ball Mills (grinding equipment) are essential for ensuring the quality and MQS Mill's efficiency of the production process in these industries.

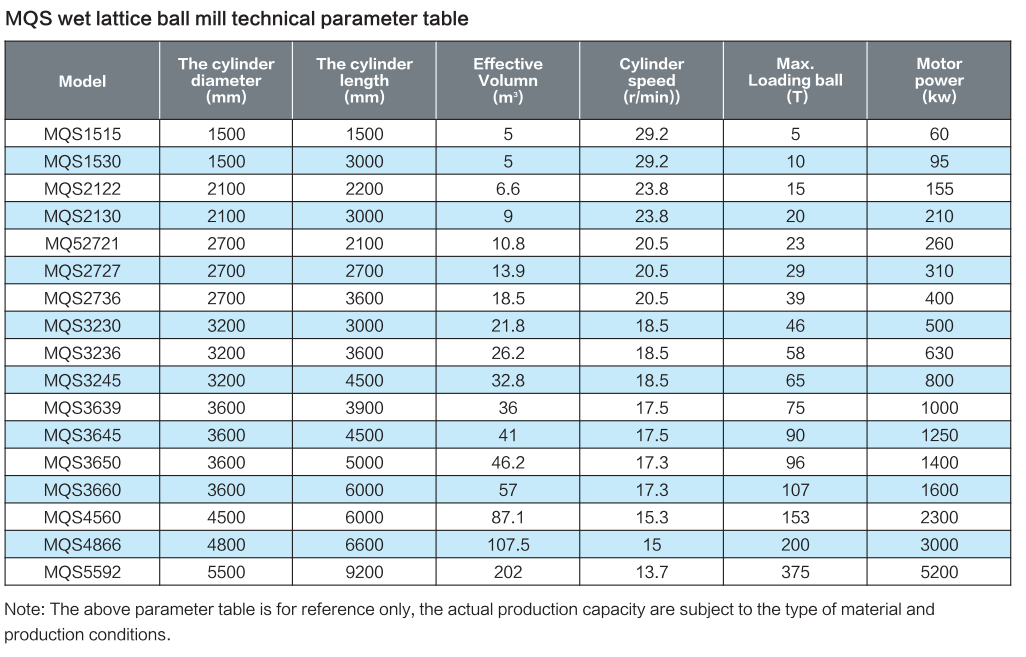

Technical Parameters of MQS Ball Mills

Advantages of MQS Ball Mills

1. High grinding efficiency: Lattice plate discharge structure enables forced pulp discharge, shortening pulp residence time in the cylinder to avoid over-grinding. Output is 10%-20% higher than overflow-type ball mills under the same conditions, meeting large-scale production demands.

2. Uniform product particle size: Optimized internal structure and grinding media configuration ensure uniform material grinding. Consistent particle size improves subsequent separation/processing efficiency (e.g., higher mineral recovery rate and concentrate grade in mineral processing).

3. Wide adaptability: Suitable for materials of different hardnesses (iron ore, quartzite, non-ferrous metal ores) and particle sizes. Adjustable liner types and steel ball grading meet primary/secondary grinding requirements.

4. Solid and durable structure: Cylinder welded from high-quality steel plates with end cover reinforcing ribs for enhanced strength/rigidity. Wear-resistant liners (e.g., high-manganese steel) extend service life and reduce maintenance costs.

5. Easy operation & maintenance: Simple structure with easily installable/disassemblable key components (cylinder, hollow shaft, transmission parts). Convenient inspection/replacement of discharge components (e.g., lattice plate) for stable operation.

6. Energy-saving performance: New models feature optimized efficient transmission systems and energy-saving motors. Reasonable grinding processes improve energy utilization, reducing operational energy costs.

7. Strong closed-circuit circulation adaptability: Works seamlessly with classifiers (e.g., spiral classifiers) in closed-circuit systems. Unqualified particles are returned for re-grinding, ensuring product quality and system efficiency/stability.

Application scenarios of MQS Ball Mill

1. Applicable materials: For the MQS Mills (grinding equipment), the applicable materials include steel slag, lime, gold ore, aluminum powder, quartz sand, aluminum paste, hematite, high-alumina porcelain, iron ore concentrate, fluorite, barite, coal slime, potassium feldspar, and so on. These materials can be effectively processed by the MQS Mills, taking advantage of its unique grinding structure and performance. In the process of dealing with these materials in the MQS Mills, the characteristics of the MQS Mills ensure the efficiency and quality of grinding.

2. Application range of mills: The MQS Mills (grinding equipment) are widely applied in various production industries. It is extensively used in industries such as cement production, new building materials manufacturing, refractory materials processing, fertilizer production, and metal beneficiation. Also, the MQS Mills (grinding equipment) play an important role in the glass and ceramics industries. In the cement industry, MQS Mills help in grinding raw materials to meet the requirements of cement production. In the new building materials and refractory materials industries, the MQS Mills contribute to the processing of relevant materials to obtain products with the desired properties. For metal beneficiation, the MQS Mills are crucial for the grinding and preparation of ores. And in the glass and ceramics industries, the MQS Mills are used to process materials to ensure the quality of the final products.

Performance Features of MQS Ball Mills

1. Fine grinding particle size: MQS Ball Mills (grinding equipment) are usually used to grind materials to 1/4 inch and finer. These MQS Ball Mills (grinding equipment) are capable of grinding materials to a particle size ranging from 20 to 75 micrometers, which can meet the MQS Ball Mill's process requirements that demand a high level of product fineness. MQS Ball Mills (grinding equipment) are especially suitable for applications where fine grinding is crucial, ensuring that the final products meet strict quality standards in terms of particle size.

2. High working efficiency: MQS Ball Mills operate in a closed-circuit system. In this system, oversized materials can be continuously recycled back to the MQS Ball Mills for re-grinding. Thanks to MQS Ball Mill reasonable structural design and operation parameters of MQS Ball Mill (grinding equipment), a relatively high grinding efficiency can be achieved. The closed-circuit operation mode of MQS Ball Mill maximizes the utilization of materials and reduces the waste of unqualified products, thus improving MQS Ball Mill's overall production efficiency.

3. Wide application range: MQS Ball Mills are widely applied in industries such as building materials, chemical engineering, and mineral processing. MQS Ball Mills can be used to grind a variety of ores and other materials. MQS Ball Mills can also be used for the pre-treatment of ores before MQS Ball Mill's separation process. Whether MQS Ball Mills are in the production of building materials where precise grinding of raw materials is required or in the chemical industry for processing specific materials, MQS Ball Mills demonstrate their versatility and adaptability in different industrial scenarios.

Our Service for MQS Ball Mill

We are dedicated to providing professional, efficient support throughout your MQS Ball Mill procurement and commissioning, ensuring optimal production matching and smooth startup.

1. Pre-Sales Consultation & Matching

Demand Analysis & Model Selection: Our technical team communicates in-depth to clarify core requirements (material type, grinding fineness, hourly output, dry/wet grinding method) and recommends the most suitable MQS model.

Site Adaptation & Integration Guidance: Provide detailed technical drawings (dimensions, foundation load, power supply). For existing production line integration, analyze existing equipment/feeding system parameters to ensure seamless connection and avoid mismatches or blockages.

2. In-Sales Quality & Delivery Guarantee

Production Progress Tracking: Regularly share production reports post-order to keep you updated on schedule and estimated delivery.

Logistics & Packaging: Cooperate with heavy machinery-experienced international logistics partners, offering flexible terms (FOB/CIF) and full-process tracking for on-time, intact delivery.

3. Technical Documentation & Guidance

Provide comprehensive technical documents related to MQS Ball Mills (operation manual, installation diagram, troubleshooting guide) covering working principle, operation steps, and common problem solutions.

Our Company

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+ m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mills, heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.