- Home

- Products

- Case

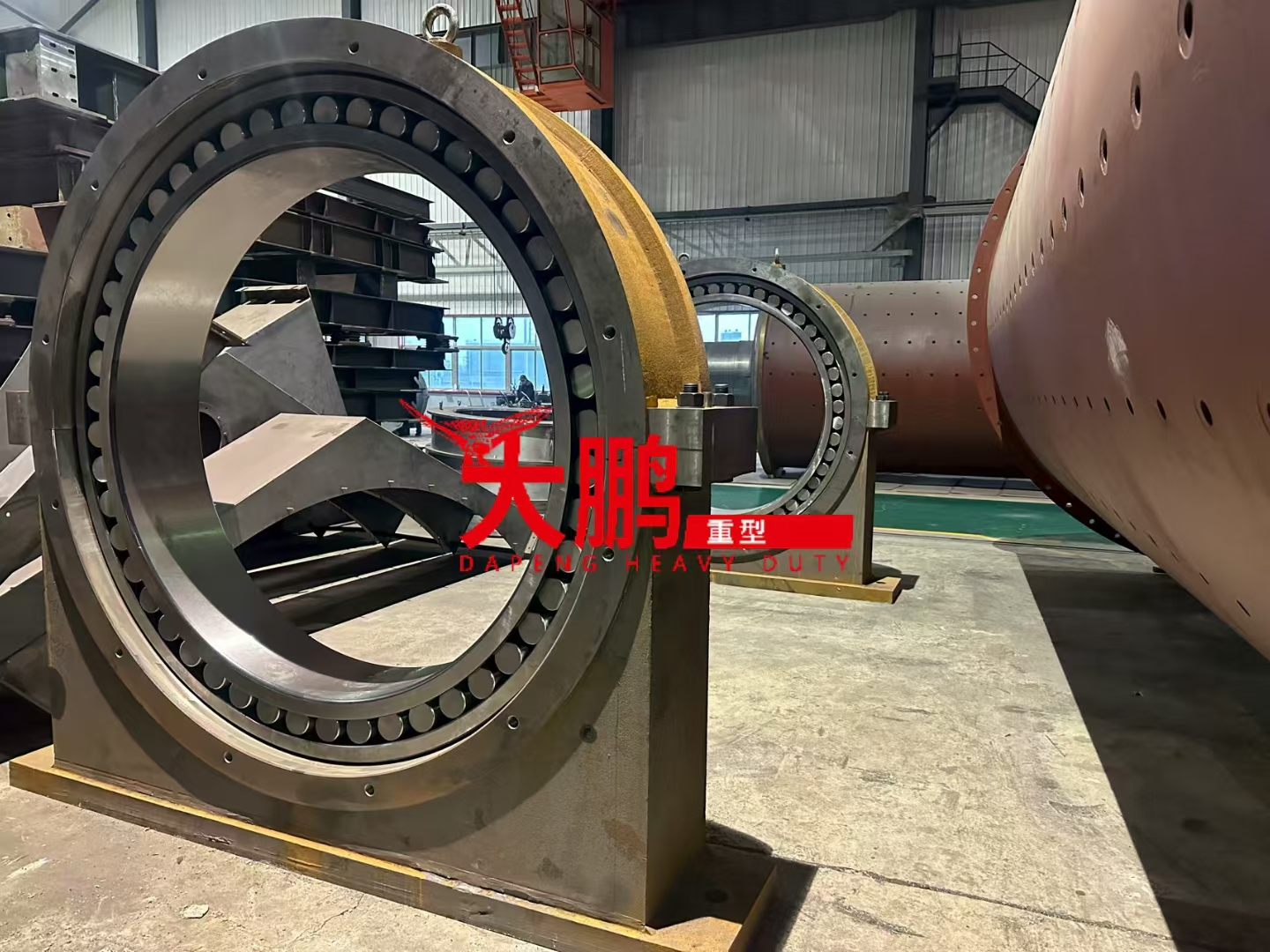

- Factory Show

- News

- video

- About Us

- Contact Us

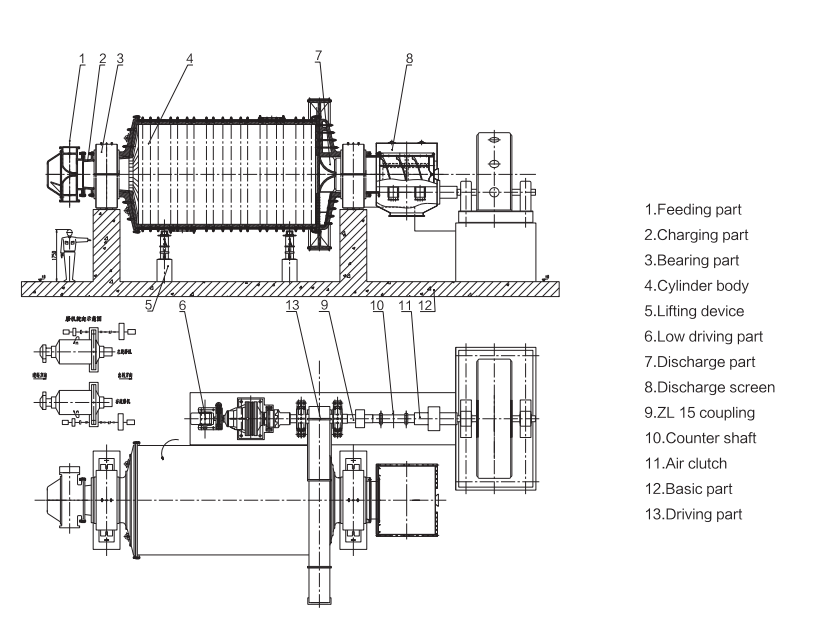

Diagram of MQY Mill (MQY Ball Mill)

Introduction of MQY Mill (MQY Ball Mill)

MQY ball mill is an industrial grinding equipment, mainly used for crushing and grinding materials. MQY Mill is widely used in many industries such as mineral processing, building materials, chemicals, metallurgy, etc., for grinding various ores and other materials.

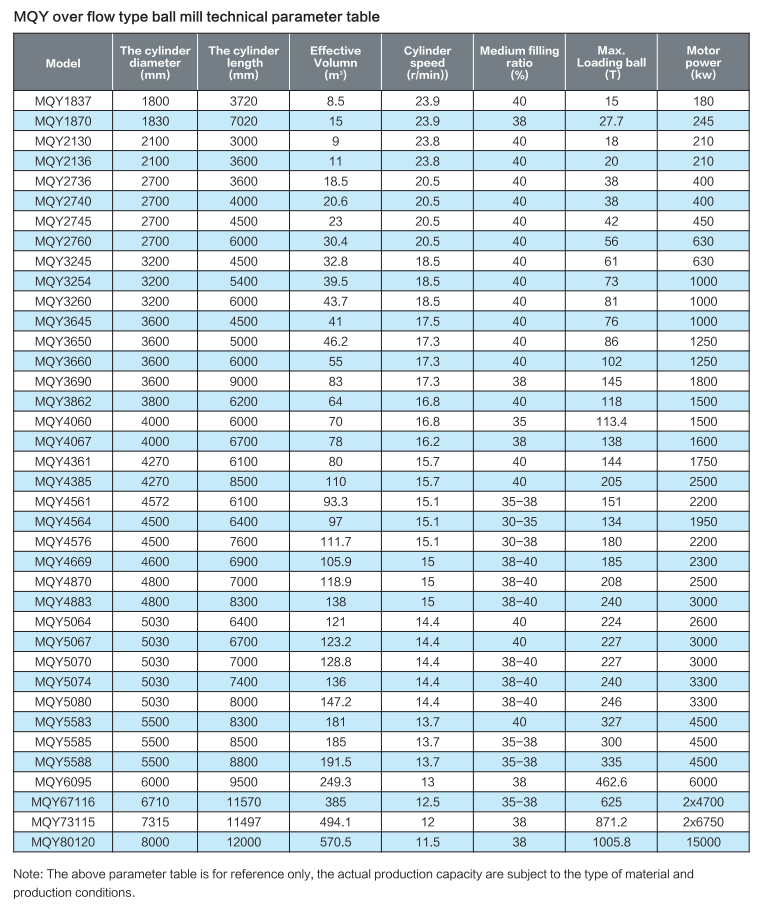

Technical Parameters of MQY Mill (MQY Ball Mill)

Working principle of MQY Mill (MQY Ball Mill)

The working principle of MQY Mill is that the motor drives the cylinder to rotate through the transmission device, so that the internal grinding medium (steel ball) is lifted to a certain height under the action of centrifugal force and then falls down, impacting and grinding the material, so that the material is crushed by MQY Mill to the required particle size and discharged naturally from the discharge end of the MQY Mill through overflow.

Application scenarios of MQY Mill (MQY Ball Mill)

MQY Mill is mainly used in the grinding operation of mining, building materials, metallurgy and other industries, especially for fine grinding operation. MQY Mill is generally used for the second stage grinding in the two-stage grinding operation. MQY Mill can grind the ore particle size even finer. MQY Mill grinds various ores in the mineral processing industry to fully separate the useful minerals from the gangue minerals in the ore, and improve the MQY Mill's processing efficiency. In addition, MQY Mill is also widely used in the production of building materials such as cement and ceramics, as well as the preparation of chemical raw materials.

Performance Advantages of MQY Ball Mill

1. Excellent fine-grinding effect: The MQY Mill allows the ore pulp to stay in the cylinder for a relatively long time, ensuring thorough grinding. As a result, the discharged material has a relatively fine particle size, typically less than 0.2mm. This makes the MQY Mill highly suitable for fine-grinding operations, such as secondary grinding or fine-particle classification grinding in combination with a hydrocyclone.

2. Simple structure: Compared with some other types of ball mills, the MQY Mill has a relatively simple structure. It does not have complex discharge devices like lattice plates, which makes its operation and maintenance convenient.

3. High-quality products: The MQY Mill can grind materials more uniformly, producing products with a uniform particle size and an increased specific surface area. It can provide high-quality raw materials for the production of high-grade cement and other products.

4. Energy-saving: Some improved MQY Mills use rolling bearings instead of sliding bearings. This significantly reduces friction, making it easier to start the MQY Mill. Compared with old-style ball mills, the MQY Mill can save 10%v15% of power consumption.

Structural Features of MQY Ball Mill

1. Cylinder: In the MQY Ball Mill, the cylinder is a crucial component. The cylinder of the MQY Ball Mill is generally fabricated by welding steel plates. When it comes to the MQY Ball Mill, both ends of its cylinder are closed with end covers. And on the outer sides of the end covers of the MQY Ball Mill, there are usually reinforcing ribs installed. For the MQY Ball Mill, there exists an opening right in the middle of the cylinder. This opening in the cylinder of the MQY Ball Mill is designed for the easy addition and screening of steel balls. Moreover, the inner wall of the cylinder in the MQY Ball Mill is generally lined with liners. These liners in the MQY Ball Mill serve the purpose of protecting the cylinder and enhancing the grinding efficiency of the MQY Ball Mill.

2. Liners: The liners are also an important part of the MQY Mill (MQY Ball Mill). The liners of the MQY Ball Mill come in a wide variety of forms. In the case of the MQY Ball Mill, generally, wave-shaped and long-strip-shaped liners are frequently employed. In the MQY Ball Mill, these liners are in direct contact with the grinding media. And in the MQY Ball Mill, they are vulnerable parts. Regarding the MQY Mill, they are mainly made of wear-resistant high-manganese steel, which is essential for the long-term operation of the MQY Ball Mill.

3. Hollow shaft: The hollow shaft of the MQY Mill is made of cast steel. MQY Ball Mill serves as the passage for materials to enter and exit the cylinder of Ball Mill. Meanwhile, Ball Mill supports the cylinder and enables Ball Mill to rotate.

4. Transmission part: The transmission part of the MQY Mill includes a reducer, a small transmission gear, a motor, etc. The low-speed synchronous motor of Ball Mill drives the small gear to rotate through a coupling. The small gear of Ball Mill meshes with the large gear fixed on the cylinder shell to make the cylinder rotate, providing power for the operation of the MQY Mill.

5. Discharge end: The discharge end of the MQY Mill adopts a cone-shaped design. This design of Ball Mill not only increases the volume but also forces the materials and steel balls at the cone end to be automatically classified. The closer to the outlet, the smaller the diameter of the steel balls, which enhances the repeated grinding effect.

Our Service of MQY Ball Mill

1. Pre-Sales Customized Consultation of MQY Mill

Demand Matching & Model Selection: Our technical team will conduct in-depth communication to clarify your core requirements, including the type of material to be ground (e.g., ore, cement clinker, chemical raw materials), required grinding fineness, hourly output target, and site installation conditions (space for cylinder length/diameter, power supply parameters).

If you need to integrate the mill into an existing production line (such as a mineral processing line), our team will analyze the parameters of your existing feeding and discharging systems to ensure seamless connection and avoid material blockage or mismatched capacity.

2. In-Sales Quality Control & Delivery Guarantee

Production Progress Tracking: After order confirmation, we will regularly send you production progress reports, so that you can clearly know the equipment’s production schedule and estimated delivery time.

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) to ensure it is delivered to your designated site intact and on time.

3. Technical Guidance & Documentation Support

We provide comprehensive technical documents, including operation manuals, installation diagrams, and troubleshooting guides, which detail MQY Mill working principle, operation steps, and common problem solutions for your reference.

Our Company

Dapeng is one of the most famous companies in the field of crusher in China, specializing in the production of crushing and mineral processing machinery, integrating design and development, processing and manufacturing, pre-sales and after-sales service.

Dapeng has more than 200 employees, more than 30 middle and senior technical personnel, more than 35,000 square meters of standardized plant. Crusher developed by Dapeng is widely used in mining, cement, highway, electric power, metallurgy and other industries.

Our core products are PXZ rotary crusher, European jaw crusher, DPCS/DPCH hydraulic cone crusher, DPHP hydraulic cone crusher, PYS Symons cone crusher, VSI crusher, MQY mill, heavy apron feeder, vibrating feeder and vibrating screen. As well as premium OEM-quality standard parts compatible with popular brands, such as Metso HP series, Sandvik CH/CS cone crushers, and more.

Shenyang Dapeng adheres to the survival principle of leading technology, reliable quality, reasonable price and considerate service, adheres to the enterprise spirit of "professionalism, efficiency and pragmatism", and takes customer satisfaction as the goal. We warmly welcome customers at home and abroad to visit us for guidance, consultation and negotiation.