- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

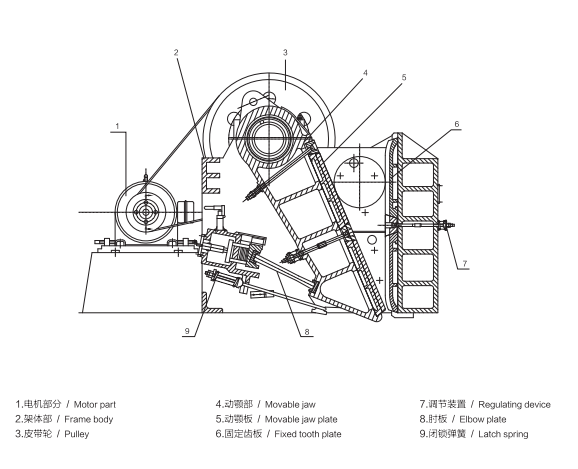

Diagram of PEF Jaw crusher

Introduction of PEF Jaw Crusher

PEF jaw crusher is also a spring-safe cone crusher, which has created a new concept of crushing materials and is an ideal equipment for more crushing and less grinding. It has the characteristics of high productivity, fine product size, good product shape, light equipment weight, convenient maintenance and easy operation. No matter in terms of output, product particle size uniformity, product fineness, component life, operation rate and production maintenance management costs, its performance is better than that of spring cone crusher.

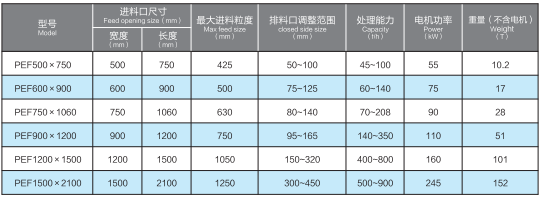

Technical Parameters of PEF Jaw crusher

Advantages of PEF Jaw Crusher

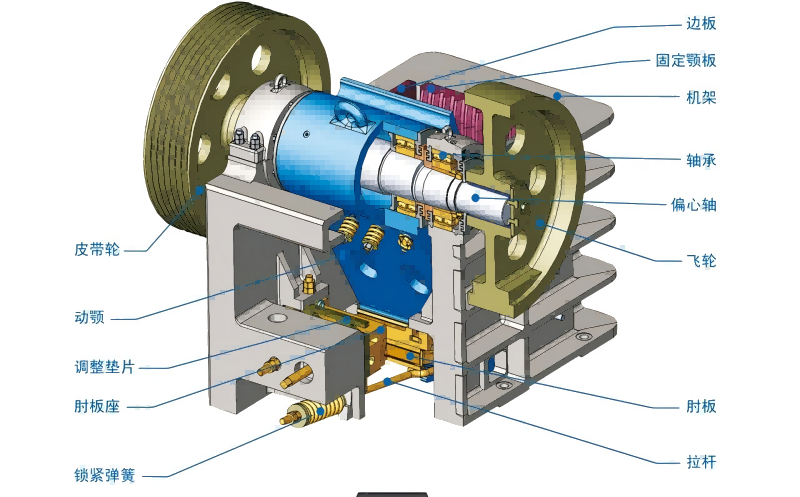

1. Good stability and high reliability:

The dynamic collar assembly is made of high-quality cast steel parts, and the heavy eccentric shaft is processed by forging billet. All of this makes the jaw crusher stable. Compared with other crushers of the same specifications, we use larger and more durable eccentric shaft bearings to give it a higher load-bearing capacity and ensure its reliability.

2. Advanced technology and long service life:

Adopting the best manufacturing technology and using advanced digital component processing equipment to ensure the density of machine components; selecting good manufacturing materials greatly increases its compression resistance and wear resistance, and greatly extends the service life of the machine.

3. Simple structure and convenient maintenance:

After continuous improvement and optimization, while ensuring the performance of the machine, the machine structure has also been simplified. The entire machine is easier to operate, maintenance is more convenient, and downtime and maintenance time are greatly shortened.

4. Large production capacity and good particle shape:

Adopting advanced crushing principles, the proportion of cubes in the product is significantly increased, the needle-like stones are reduced, and the particle size is more uniform.

Working principle of PEF Jaw Crusher

1. Swinging of movable jaw: PEF jaw crusher is mainly composed of two jaw plates, one of which is fixed and is called the fixed jaw plate, and the other jaw plate can swing within a certain range, which is called the movable jaw plate. The movement of the movable jaw plate is a periodic reciprocating motion around the suspension shaft, sometimes approaching the fixed jaw plate and sometimes leaving it.

2. Material crushing process: When the movable jaw plate approaches the fixed jaw plate, the material between the two jaw plates is crushed by the combined action of extrusion, splitting and bending and breaking. In this process, the material is effectively crushed and crushed, and finally forms the material of the required particle size.

3. Material discharge: When the movable jaw plate leaves the fixed jaw plate, the crushed material is discharged from the discharge port of the crusher under the action of gravity. This process is carried out periodically. With the continuous rotation of the motor, the movable jaw plate performs periodic crushing and discharge to achieve batch production.

Application scenarios of PEF Jaw Crusher

PEF jaw crusher is widely used in metallurgy, mining, building materials, silicate and chemical industries. In the mineral processing industry, it is generally used for coarse and medium crushing of hard or medium hard ores.

FAQ

1. What is the core advantage of the PEF Jaw Crusher compared to other traditional crushers?

Its overall performance is superior in multiple aspects: higher productivity, finer and more uniform product particle size, better product shape, lighter equipment weight, more convenient maintenance and operation. It also has advantages in component service life, operation rate and production maintenance management costs.

2. What materials and crushing stages is the PEF Jaw Crusher suitable for?

It is mainly used for coarse and medium crushing of hard or medium-hard ores. It is widely applicable in metallurgy, mining, building materials, silicate and chemical industries, especially in the mineral processing industry.

3. Why does the PEF Jaw Crusher have high stability and reliability?

Its dynamic collar assembly uses high-quality cast steel parts, and the heavy eccentric shaft is processed from forged billets. Compared with crushers of the same specification, it adopts larger and more durable eccentric shaft bearings, which enhances load-bearing capacity and ensures reliable operation.

4. What makes the PEF Jaw Crusher have a long service life?

It adopts advanced manufacturing technology and digital component processing equipment to ensure the density of machine components. At the same time, high-quality manufacturing materials are selected, which greatly improves the compression resistance and wear resistance of the equipment, thus extending its service life.

5. Is the PEF Jaw Crusher easy to maintain?

Yes. After continuous improvement and optimization, its structure is simplified while ensuring performance. The whole machine is easy to operate, maintenance work is more convenient, and downtime and maintenance time are significantly shortened.

6. What are the characteristics of the product crushed by the PEF Jaw Crusher?

It adopts advanced crushing principles, which significantly increases the proportion of cubic products, reduces needle-like stones, and makes the product particle size more uniform, with good overall particle shape.

Our Service of PEF Jaw Crusher

1. Customized Consultation of PEF Jaw Crusher

Needs Assessment: Our technical team will conduct in-depth communication with you to understand your project requirements, including daily output expectations, material characteristics (hardness, particle size of ores like iron ore, granite, basalt, etc.), and crushing stage (coarse or medium crushing), so as to recommend the most suitable PEF Jaw Crusher model and configuration.

Solution Design: For large-scale mining, metallurgical beneficiation or building materials production lines, we can provide matching suggestions for the integration of the PEF Jaw Crusher with your existing equipment (feeders, conveyors, screening equipment), ensuring seamless connection and optimized overall production efficiency.

2. Professional Support of PEF Jaw Crusher

Production Progress Tracking: After order confirmation, we will regularly update you on the manufacturing progress of the equipment, including the production status of core components (dynamic collar assembly, eccentric shaft, fixed jaw plate, movable jaw plate) and the estimated delivery time, keeping you fully informed.

3. Logistics & Packaging Guarantee of PEF Jaw Crusher

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) to ensure it is delivered to your designated site intact and on time.

4. Technical Documentation Support of PEF Jaw Crusher

We provide technical documents, including operation manuals, installation diagrams, and troubleshooting guides, which specify the equipment's working principle, operation steps, and common problem solutions (such as unstable operation, uneven product particle size) for your reference.

Our Company

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+ m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mills, heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.