- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

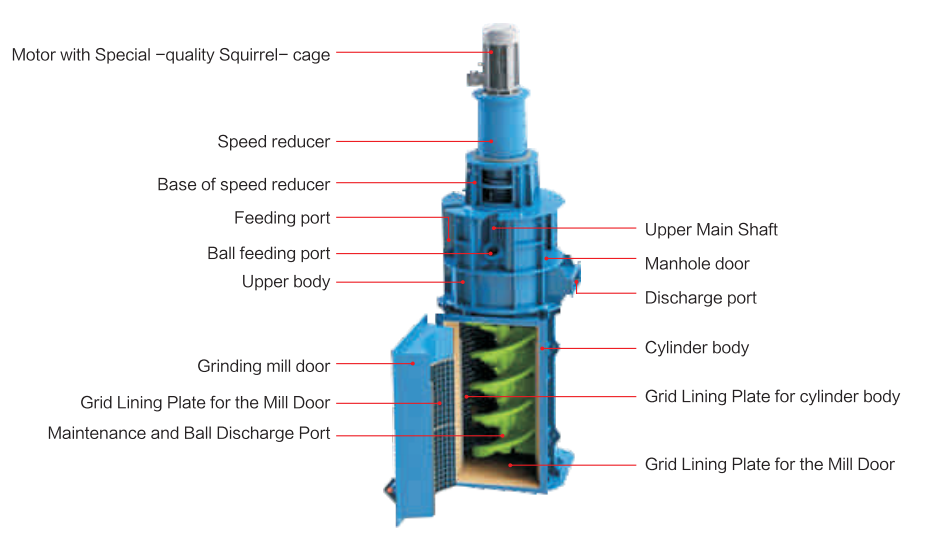

Diagram of PTM Tower Mill (Grinding Equipment)

Introdution of PTM Tower Mill

PTM Tower Mills (grinding equipment) is a specialized equipment for the ultra-fine grinding of ores and other materials, featuring a rather unique structure. Its main components include a cylindrical shell, a stirring screw, accompanied by bearings and a transmission device. During the operation of PTM Tower MillS, the stirring screw rotates continuously at a relatively low speed inside PTM Tower Mills cylindrical shell. Under the combined influence of centrifugal force, gravitational force, and frictional force, the crushing medium and the materials form an orderly motion cycle system. Inside Tower Mills stirring screw, the materials move in a spiral upward manner at a speed lower than the lifting rate. While between the inner lining of the PTM tower mill and Tower Mills outer edge of the stirring screw, the materials move in a spiral downward direction. During this process, the materials are subjected to various forces such as extrusion and grinding, thus achieving the purpose of crushing.

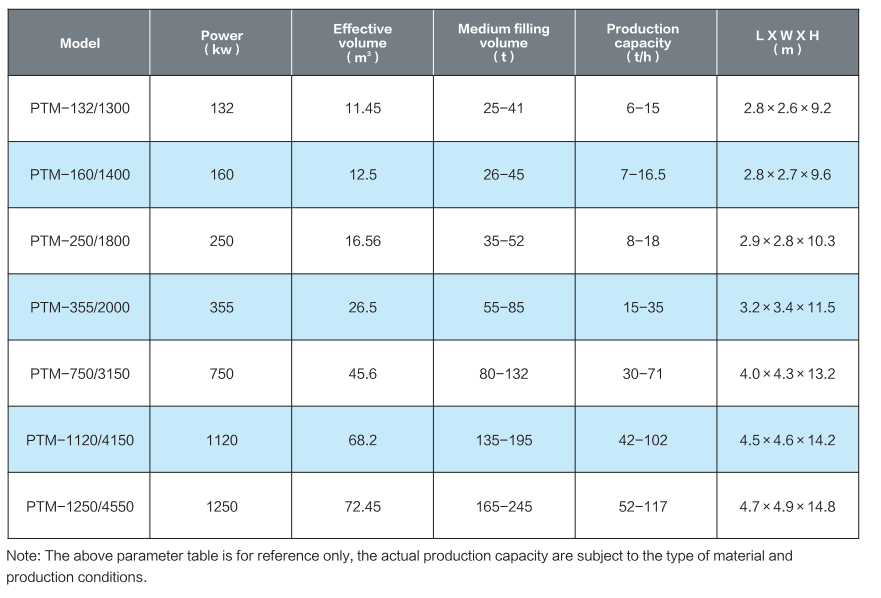

Technical Parameters of PTM Tower Mills

Working principle of PTM Tower Mil

When in operation, the PTM Tower Mill's stirring screw rotates at a relatively low speed. Centrifugal force, gravity, and friction work together to form an orderly circulation system of crushing medium and materials—macroscopically stable and balanced. Materials rise slowly along the spiral track inside the screw (at a speed lower than the lifting rate) and fall back along the spiral path in the gap between the mill liner and the screw's outer edge.

Microscopically, uneven force distribution creates dynamic speed differences between materials and the crushing medium, with constantly changing force conditions. In this environment, materials are subjected to strong extrusion and grinding, along with particle fracture, micro-shearing, and splitting. Once ground to the qualified size, materials are carried by the conveying medium to the built-in classifier, then automatically overflow from the upper cylinder.

The PTM Tower Mill features high compactness between the crushing medium and materials, significantly reducing collisions between balls, balls and liners, and balls and the screw. Macroscopic force balance of rotating components minimizes the support system load and bearing energy consumption, while facilitating qualified materials to reach the discharge port. As a stirring mill, it operates at a lower speed than similar equipment, with no relative motion between internal mechanical parts and the stirring medium in an orderly rolling state—expanding its application scope.

Application scenarios of PTM Tower Mill

PTM tower mill is mainly used for fine grinding of non-ferrous metals, gold and non-metallic minerals, especially in the second stage grinding, third stage grinding and concentrate regrinding operations of metal mines and non-metallic mines.

Technical Advantages of PTM Tower Mill

1. Enhanced Grinding Efficiency

PTM Tower Mills (grinding equipment) significantly improve grinding efficiency. PTM Tower Mills (grinding equipment) occupy a small footprint, produce minimal noise, and reduce energy consumption. Their optimized design enables them to quickly process materials, maximizing output in a shorter time.

2. Maintenance and Inspection Made Easy

PTM Tower Mills (grinding equipment) feature a user-friendly design. The lower part of the cylinder of PTM Tower Mills (grinding equipment) has a door-opening design. This makes daily maintenance and inspection a breeze, allowing technicians to easily access the interior for any necessary upkeep.

3. Superior Product Quality

PTM Tower Mills ensure top-notch product quality. The secondary sedimentation separation of grinding particles in PTM Tower Mills (grinding equipment) can evenly control the particle size distribution. As a result, the qualified fraction of the product increases, meeting the high-standard requirements of various industries.

4. Extended Service Life

The inner wall of PTM Tower Mills (grinding equipment) is equipped with a wear-resistant lining plate. Made of domestically leading magnetic rubber material, this lining plate effectively reduces wear and tear, prolonging the service life of PTM Tower Mills (grinding equipment). In sum, PTM Tower Mills offer a combination of high performance, easy maintenance, excellent product quality, and long-term durability.

Our Service of PTM Tower Mills

1. Customized Consultation PTM Tower Mill (Grinding Equipment)

Needs Assessment: Our technical team will conduct in-depth communication with you to understand your project requirements, including daily output expectations, material characteristics, so as to recommend the most suitable PTM Tower Mills.

2. Professional Support PTM Tower Mill (Grinding Equipment)

Production Progress Tracking: After order confirmation, we will regularly update you on the manufacturing progress of the equipment, including the production status of core components and the estimated delivery time, keeping you fully informed.

3. Logistics & Packaging Guarantee PTM Tower Mill (Grinding Equipment)

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) to ensure it is delivered to your designated site intact and on time.

4. Technical Documentation & Guidance of PTM Tower Mill (Grinding Equipment)

We provide comprehensive technical documents, including operation manuals, installation diagrams, and troubleshooting guides, which detail the equipment's working principle, operation steps, and common problem solutions for your reference.

About Our Company

Dapeng is one of the most famous companies in the field of crusher in China, specializing in the production of crushing and mineral processing machinery, integrating design and development, processing and manufacturing, pre-sales and after-sales service.

Dapeng has more than 200 employees, more than 30 middle and senior technical personnel, more than 35,000 square meters of standardized plant. Crusher developed by Dapeng is widely used in mining, cement, highway, electric power, metallurgy and other industries.

Our core products are rotary crusher, European jaw crusher, DPCS/DPCH hydraulic cone crusher, DPHP hydraulic cone crusher, PYS Symons cone crusher, VSI crusher, ball mill, heavy apron feeder, vibrating feeder and vibrating screen. As well as premium OEM-quality standard parts compatible with popular brands, such as Metso HP series, Sandvik CH/CS cone crushers, and more.

Shenyang Dapeng adheres to the survival principle of leading technology, reliable quality, reasonable price and considerate service, adheres to the enterprise spirit of "professionalism, efficiency and pragmatism", and takes customer satisfaction as the goal. We warmly welcome customers at home and abroad to visit us for guidance, consultation and negotiation.