- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

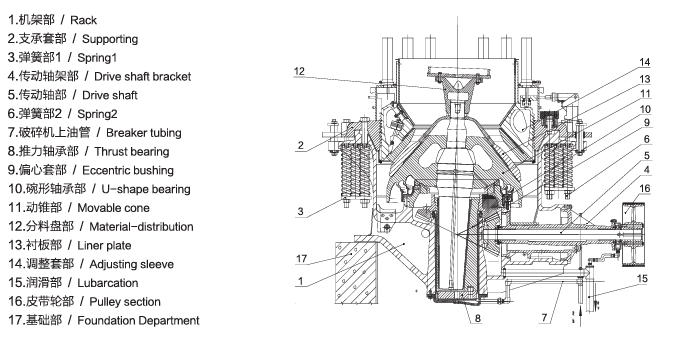

Diagram of PYS Symons Cone Crusher (Symons Spring Cone Crusher)

Introduction of PYS Symons Cone Crusher (Spring Cone Crusher)

PYS Symons Crusher is also a spring-safe circular crusher. PYS Symons Crusher has created a new concept of crushing materials and PYS Symons Crusher is an ideal equipment for more crushing and less grinding. PYS Symons Crusher has the characteristics of high productivity, fine product size, good product shape, light equipment weight, convenient maintenance and easy operation. No matter in terms of output, product particle size uniformity, product fineness, component life, operation rate and production maintenance management costs, the performance of PYS Symons Crusher is better than that of Symons Crusher (spring cone crusher).

Advantages of PYS Symons Cone Crusher (Spring Cone Crusher)

1. PYS Symons Crusher's High-Efficiency Crushing Performance: PYS Symons Crusher delivers exceptional crushing force through optimized kinematics design, achieving 25-30% higher production capacity compared to conventional models while maintaining energy efficiency.

2. PYS symons cone crusher Dual-Chamber Configuration Flexibility: Featuring standard and short-head chamber configurations, Symons Crusher adapts to various feed sizes (max. 300mm) and product requirements (adjustable discharge 6-38mm), with a throughput range of 45-1270 TPH depending on chamber selection.

3. PYS Symons cone crusher multi level crushing capability: This Spring Cone Crusher's system is equipped with two crusher specifications (B/D), each providing three interchangeable lining profiles, achieving progressive reduction ratios in different stages of crushing applications.

4. PYS Symons spring cone crusher has intelligent Overload Protection system integrates:

PLC-controlled auto-recovery sequence

5. PYS Symons Crusher has Advanced Lubrication System: Dual-circuit oil filtration;Temperature-controlled circulation (40-55℃ operating range);Flow monitoring sensors; high pumping capacity.

6. Compared with traditional Crusher, PYS Symons Crusher adopts wave pressure locking, hydraulic adjustment, hydraulic cavity cleaning and other devices, and the automation intensity is greatly improved.

7. PYS Symons Crusher has high design and manufacturing quality, long service life, reduction in routine service time, low cost, and all maintenance work can be easily carried out on the upper part of the machine.

8. PYS Symons Crusher's Strong adaptability: -40℃ to +60℃ ambient operation;PYS Symons Crusher's multi-stage air filtration;Corrosion-resistant coating.

9. PYS Symons Crusher's Good stability and high durability: PYS Symons Crusher's reliable design, excellent component material, and processing accuracy provide guarantees for the stability and durability of the equipment.

10. PYS Symons Crusher's Convenient cavity cleaning: The hydraulic cavity cleaning system can quickly clean the crushing cavity and greatly reduce downtime.

11. Complete product and multiple crushing chamber types: PYS Symons Crusher has four specifications, each specification has standard type and short head type, and each model is equipped with multiple crushing chamber types, which can better adapt to the needs of medium and fine crushing operations in different crushing processes.

Technical Parameters of PYS symons cone crusher (Spring Cone Crusher)

| PYS Symons Cone crusher | ||||||||

| Model | Crushingfeet (mm) | Diagramof Chamber | Min.Discharge (mm) | Motor | Total Weight (t) | |||

Closed Inlet | Opening Outlet | Type | Power (kW) | |||||

| PYS-B0910 | 3 900 | F | 83 | 102 | 10 | Y315S-6 | 75 | 9.98 |

| PYS-B0917 | C | 159 | 175 | 13 | ||||

| PYS-B0918 | EC | 163 | 178 | 25 | ||||

| PYS-D0904 | 3 900 | F | 13 | 41 | 3 | 10.5 | ||

| PYS-D0906 | F | 33 | 61 | 3 | ||||

| PYS-D0907 | C | 51 | 76 | 6 | ||||

| PYS-B1313 | 41/4 1295 | F | 109 | 137 | 13 | JS126-6 | 155 | 24.2 |

| PYS-B1321 | M | 188 | 210 | 16 | ||||

| PYS-B1324 | C | 216 | 241 | 19 | ||||

| PYS-B1325 | EC | 238 | 259 | 25 | ||||

| PYS-D1306 | 41/4 1295 | F | 29 | 64 | 3 | 24.6 | ||

| PYS-D1308 | M | 54 | 89 | 6 | ||||

| PYS-D1310 | C | 70 | 105 | 10 | ||||

| PYS-D1313 | EC | 98 | 133 | 16 | ||||

| PYS-B1620 | 51/2 1676 | F | 188 | 209 | 16 | JS136-6 | 240 | 45 |

| PYS-B1624 | M | 213 | 241 | 22 | ||||

| PYS-B1626 | C | 241 | 268 | 25 | ||||

| PYS-B1636 | EC | 331 | 368 | 38 | ||||

| PYS-D1607 | 51/2 1676 | F | 35 | 68 | 5 | 45.6 | ||

| PYS-D1608 | M | 54 | 89 | 6 | ||||

| PYS-D1613 | C | 98 | 133 | 10 | ||||

| PYS-D1614 | EC | 117 | 158 | 13 | ||||

| PYS-B2127 | 7 2134 | F | 253 | 278 | 19 | Y400/Y450-6 | 400 | 104 |

| PYS-B2133 | M | 303 | 334 | 25 | ||||

| PYS-B2136 | C | 334 | 369 | 31 | ||||

| PYS-B2146 | EC | 425 | 460 | 38 | ||||

| PYS-D2110 | 7 2134 | F | 51 | 105 | 5 | 105 | ||

| PYS-D2113 | M | 95 | 132 | 10 | ||||

| PYS-D2117 | C | 127 | 178 | 13 | ||||

| PYS-D2120 | EC | 152 | 203 | 16 | ||||

| Note: The above parameter table is for reference only, and the actual production capacity depends on the material type and production conditions | ||||||||

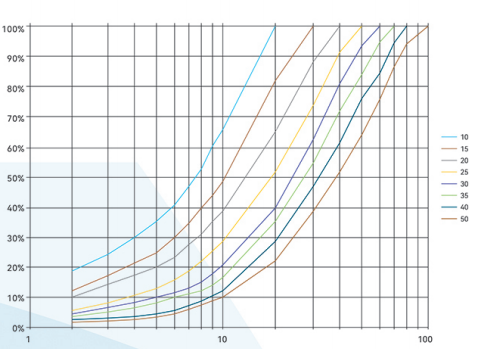

Product granularity curve of PYS Symons cone crusher (Symons Spring Cone Crusher)

Application scenarios of PYS Symons Spring Cone Crusher (Symons Spring Cone Crusher)

Metallic ores: iron, copper, and other non-ferrous metal deposits

Igneous formations: granite and quartz-based rock structures

Sedimentary materials: limestone, sandstone, and conglomerate formations

Metamorphic rocks: quartzite and similar crystalline structures

Alluvial deposits: river pebbles and other rounded aggregates

Our Service of Symons Spring Cone Crusher

1. Customized Consultation of Symons Cone Crusher

Needs Assessment: Our technical team will conduct in-depth communication with you to understand your project requirements, including daily output expectations, material characteristics (hardness, particle size of iron ore, granite, basalt, etc.), and crushing stage (secondary or tertiary crushing), so as to recommend the most suitable Symons Spring Cone Crusher model and configuration.

2. Professional Support of Symons Cone Crusher

Production Progress Tracking: After order confirmation, we will regularly update you on the manufacturing progress of the equipment, including the production status of core components (crushing cone, mortar wall, spring system) and the estimated delivery time, keeping you fully informed.

3. Logistics & Packaging Guarantee of Symons Cone Crusher

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) to ensure it is delivered to your designated site intact and on time.

4. We provide of Symons Cone Crusher's technical documents, including operation manuals, installation diagrams, and troubleshooting guides, which specify the PYS spring cone crusher's working principle, operation steps, PYS spring cone crusher's discharge port adjustment methods, and PYS spring cone crusher's common problem solutions (such as spring overload, uneven crushing) for your reference.

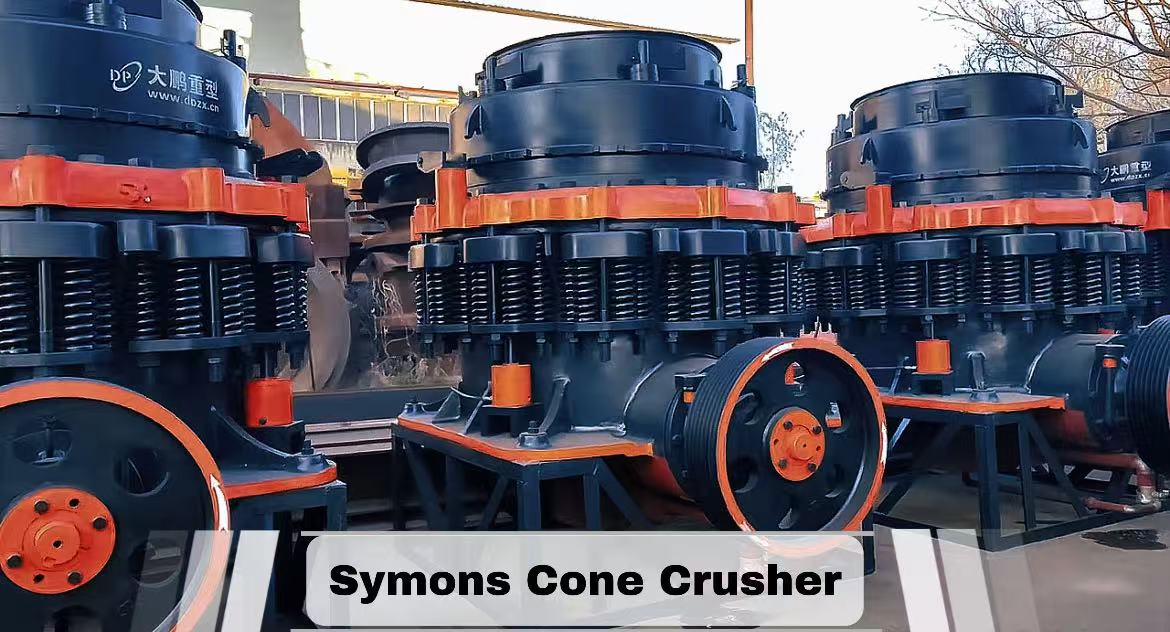

Our Company

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+ m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mills, heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.