- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

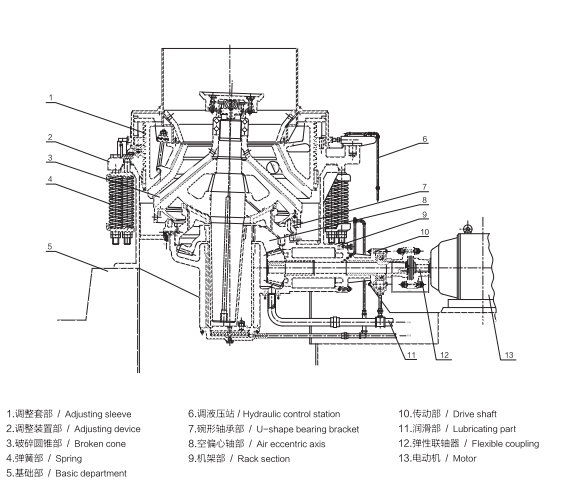

Diagram of PYT Spring Cone Crusher

Introduction of PYT Spring Cone Crusher

PYT Spring Cone Crusher is suitable for crushing various ores and rocks with medium hardness or above. It features a reliable structure, high production efficiency, convenient adjustment, and cost-effectiveness in operation. Its spring safety system serves as an overload protection device, which allows metal foreign objects to pass through the crushing chamber without damaging the machine; meanwhile, it adopts two sealing methods. Dry oil sealing and water dealing, to isolate stone powder from lubricating oil and ensure reliable operation. The type of crushing chamber is determined by the application of the ore: the Standard Type is suitable for secondary crushing, the Medium Type for fine crushing, and the Short-Head Type for extra-fine crushing.

Main Technical Parameters of PYT Spring Cone Crusher

| PYT Spring Cone Crusher | ||||||||||||

| Model | 900 | 1200 | 1750 | 2200 | ||||||||

| standard | medium | Short head | standard | medium | Short head | standard | medium | Short head | standard | medium | Short head | |

| Maximum size of feeding port (mm) | 135 | 70 | 50 | 170 | 115 | 60 | 250 | 215 | 100 | 350 | 275 | 130 |

| Recommended maximum size for feeding(mm) | 115 | 60 | 40 | 145 | 100 | 50 | 215 | 185 | 85 | 300 | 230 | 100 |

| Size of ore discharge (mm) | 15-50 | 5-20 | 3-13 | 20-50 | 8-25 | 3-15 | 25-60 | 10-30 | 5-15 | 30-60 | 10-30 | 5-15 |

| Capacity(t/h) | 50-90 | 20-65 | 15-50 | 110-168 | 42-135 | 18-105 | 280-430 | 115-320 | 75-230 | 590-1000 | 200-580 | 120-340 |

| Motor (kw) | 55 | 110 | 155/180 | 280 | ||||||||

| Motor speed(r/min) | 730 | 730 | 735 | 490 | ||||||||

| Motor voltage (v) | 380 | 380 | 380 | 6000/380 | ||||||||

| Number of spindle swings(r/min) | 333 | 300 | 245 | 220 | ||||||||

| Single group pressure of spring(t) | 70 | 150 | 250 | 400 | ||||||||

| Total weight of equipment (including motor)(t) | 10.8 | 10.8 | 10.9 | 24.7 | 25 | 25.3 | 50.3 | 50.3 | 50.2 | 80 | 81.4 | 81.6 |

Note: The above parameter table is for reference only, and the actual production capacity depends on the material type and production conditions | ||||||||||||

Advantages of PYT Spring Cone Crusher

1. PYT Spring Crusher's Sturdy and Durable: The body of Spring Crusher is made of cast steel structure, and reinforcing ribs are provided in the heavy-load parts. The structure of Spring Crusher is stable, and the service life of Spring Crusher is long.

2. PYT Spring Crusher's Convenient Adjustment: Spring Crusher is equipped with an adjuster, Spring Crusher enables quick adjustment of the particle size of the crushed materials.

3. PYT Spring Crusher's Good Sealing Performance: The internal structure of Spring Crusher has a good sealing performance. PYT Spring Crusher can effectively protect Spring Crusher from the intrusion of dust and small particles.

4. PYT Spring Crusher's Complete Lubrication System: Spring Crusher has a complete lubrication system. When the oil temperature is too high or the flow rate is too slow, the system of Spring Crusher will automatically shut down to ensure the normal operation of Spring Crusher.

Application scenarios of PYT Spring Cone Crusher

Metallurgical Industry: PYT Spring Crusher plays a critical role in crushing metal ores (e.g., iron ore, copper ore). PYT Spring Crusher efficiently reduces large mined ores to suitable particle sizes for subsequent mineral processing and smelting, boosting metal extraction rates and production efficiency, while helping metallurgical enterprises optimize processes and increase profits.

Mining Industry: PYT Spring Crusher adapts to crushing ores of varying hardness (hard granite, basalt, medium-hard limestone, quartzite, etc.). Suitable for both large-scale open-pit and underground mining operations, PYT Spring Crudher serves as a powerful tool for mining enterprises to enhance capacity and cut production costs.

Construction Industry: PYT Spring Crusher produces construction aggregates (stones, sand) meeting industry standards by crushing various rocks. With uniform particle size and regular shape, the aggregates are widely used in concrete mixing, road paving, and other construction projects, providing reliable raw material support for project quality and safety.

Chemical Industry: PYT Spring Crusher precisely controls product particle size for raw material crushing in chemical processes (e.g., calcium carbonate, gypsum ore processing). Meets strict particle size requirements of chemical production, ensuring smooth chemical reactions and stable product quality, thus improving enterprises' product competitiveness.

Water Conservancy Project Construction: PYT Spring Crusher turns mined stones into appropriate specifications for infrastructure projects such as river regulation and dam construction. Supplies sufficient construction materials for the smooth implementation of water conservancy projects, supporting the development of the water conservancy industry.

Structural Features of PYT Spring Cone Crusher

1. PYT Spring Cone Crusher's Spring Safety Device: Equipped with a dedicated spring safety mechanism. When uncrushable foreign objects enter the crushing chamber, the spring compresses to allow the movable cone to move downward, discharging the objects and protecting the equipment from damage. After discharge, the spring resets the movable cone to ensure continuous operation.

2. PYT Spring Cone Crusher's Hydraulic Adjustment System: Adopts a hydraulic system for discharge port adjustment, enabling convenient and precise control of crushing particle size to meet diverse production requirements. The system also ensures smooth movement of the movable cone, enhancing crushing stability and reliability.

3. PYT Spring Cone Crusher's Optimized Crushing Chamber: Features a uniquely designed crushing chamber with concave liners and mantles made of high-wear-resistant materials, ensuring efficient crushing and long service life. The optimized structure guarantees a reasonable material flow path, improving crushing efficiency and reducing energy consumption.

4. PYT Spring Cone Crusher's Spherical Bearing Support: The movable cone is supported by a spherical bearing, which effectively withstands large crushing forces and ensures stable operation. With excellent self-aligning performance, it adapts to small-angle swings of the movable cone during crushing, minimizing bearing wear and extending service life.

5. PYT Spring Cone Crusher's Reliable Drive Mechanism: Driven by an electric motor via V-belt and pulley, boasting a simple structure, reliable operation, and easy maintenance. The V-belt drive provides a buffering effect, reducing impact loads on the motor during startup and operation.

6. PYT Spring Cone Crusher's Compact & Robust Overall Structure: The frame is crafted from high-strength cast steel, offering high rigidity and strength to resist large impact forces during crushing. Scientific component layout ensures convenient installation, maintenance, and inspection.

FAQ of PYT Spring Cone Crusher

1. What crushing stages is the PYT Spring Cone Crusher designed for?

PYT Spring Cone Crusher is a professional medium and fine crushing equipment, engineered for secondary and tertiary crushing. It excels in processing medium to high-hardness materials (e.g., iron ore, granite, limestone, quartz), converting raw materials into qualified intermediate or finished products.

2. How do you ensure the selected model matches my production requirements?

Our technical team conducts one-on-one consultations, analyzing core factors: industry type, material characteristics (hardness, particle size), output capacity, product particle size, and site constraints. We provide tailored model recommendations to optimize efficiency and maximize ROI.

Our Service of PYT Spring Cone Crusher

1. Customized Consultation of PYT Spring Cone Crusher

Needs Assessment: Our technical team will conduct in-depth communication with you to understand your project requirements, including daily output expectations, material characteristics (hardness, particle size of iron ore, granite, basalt, copper ore, etc.), and crushing stage, so as to recommend the most suitable crusher model and configuration.

Solution Design of PYT Spring Cone Crusher: For large-scale mining, metallurgical beneficiation or bulk aggregate production lines, we can provide matching suggestions for the integration of the crusher with your existing equipment (feeders, conveyors, screening equipment, washing equipment), ensuring seamless connection and optimized overall production efficiency.

2. Professional Support of PYT Spring Cone Crusher

Production Progress Tracking: After order confirmation, we will regularly update you on the manufacturing progress of the equipment, including the production status of core components (gyratory crushing cone, concave, main shaft, hydraulic control system) and the estimated delivery time, keeping you fully informed.

3. Logistics & Packaging Guarantee of PYT Spring Cone Crusher

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) to ensure it is delivered to your designated site intact and on time.

4. We provide technical documents of PYT Spring Crusher, including operation manuals, installation diagrams, and troubleshooting guides, which specify PYT Spring Crusher's working principle, operation steps, discharge port adjustment methods, and common problem solutions (such as uneven product particle size, hydraulic system pressure abnormality) for your reference.