- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

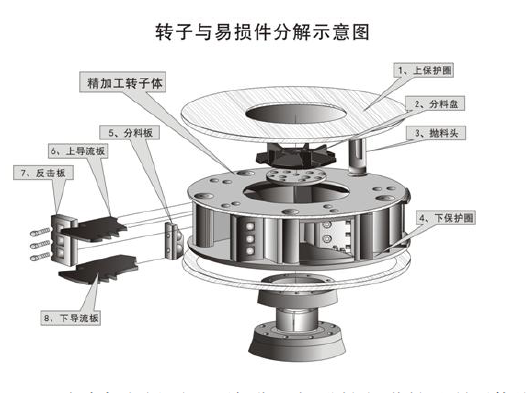

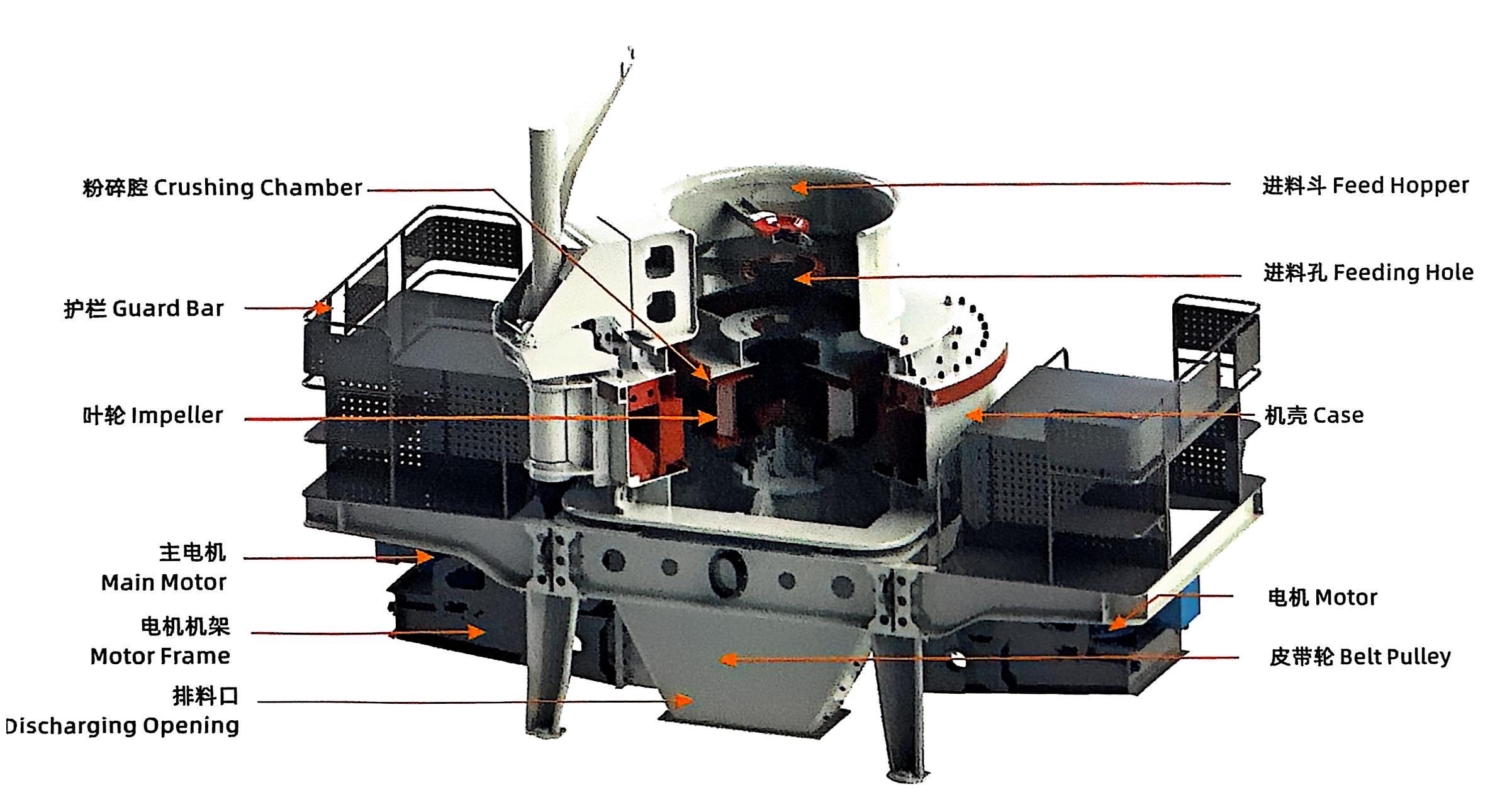

Diagram of Vertical Shaft Impact Sand Crusher

Introduction of VSI Vertical Shaft Impact Crusher

1. VSI Impact Crusher can realize the rapid conversion of two VSI Impact Crusher's crushing modes, "stone hitting stone" and "stone hitting iron", to meet VSI Impact Crusher's crushing needs of different materials.

2. VSI Impact Crusher adopts thin oil lubrication and is equipped with air cooling system, controlled by PLC and intelligent instrument, to achieve full automatic lubrication control, to ensure that VSI Impact Crusher's bearing works under ideal conditions.

3. VSI Impact Crusher has the characteristics of high-quality final products, with excellent finished product particle shape, cubic, low needle-like content and high bulk density.

Technical Parameters of VSI Vertical Shaft Impact Crusher

Structural Features of VSI Vertical Shaft Impact Crusher

1. Unique Rotor Design:The rotor is a crucial component of the VSI Impact Crusher. During the operation of the equipment, materials are rapidly accelerated to a very high speed within the rotor of the VSI Sand Making Machine and then thrown out at high speed to achieve the crushing operation. To meet the characteristics of different materials and production requirements, the VSI Sand Making Machine has designed various types of rotors, such as open rotors and closed rotors. Different rotor types are suitable for materials with different hardness and particle sizes, enabling the VSI Sand Making Machine to exert its best crushing effect.

2. Adjustable Feeding System:VSI Sand Making Machine is equipped with an externally adjustable feeding pipe. With the help of this carefully designed feeding system, operators can easily and precisely control the feeding amount and feeding speed, flexibly adapting to various complex and changeable production conditions to ensure the stable operation of the VSI Sand Making Machine.

3. Multiple Crushing Chamber Types:VSI Sand Making Machine provides multiple different crushing chamber types, such as "stone-on-stone" and "stone-on-iron". The "stone-on-stone" crushing chamber type, due to its unique design, has an excellent crushing effect on high-hardness and highly abrasive materials, such as quartz. On the other hand, the "stone-on-iron" crushing chamber type can enable the VSI Sand Making Machine to achieve higher production efficiency when dealing with medium-low hardness and moderately abrasive materials, such as granite and limestone.

4. Hydraulic Cover Opening Device:The VSI Sand Making Machine is equipped with a hydraulically controlled cover opening device. When it is necessary to inspect, maintain, or replace the internal components of the equipment, operators can easily open the upper cover of the VSI Sand Making Machine by simply operating the hydraulic system. This greatly improves the maintainability of the equipment, effectively reducing the downtime and maintenance costs of the equipment.

Advantages of VSI Sand Making Machine

1.VSI crusher's Large-scale and High-efficiency:With the continuous increase in the requirements for VSI crusher's production scale and VSI crusher's efficiency in industries such as mining and construction, VSI crusher are evolving towards VSI crusher's large-scale and VSI crusher's high-efficiency. Large-sized VSI crusher can handle a greater flow of materials, improving the VSI crusher's production capacity of a single VSI crusher machine. At the same time, through VSI crusher's optimized design and VSI crusher's advanced manufacturing processes, VSI crusher's crushing efficiency and VSI crusher's energy utilization rate of VSI crusher are further enhanced.

2.VSI crusher's Environmental Protection and Energy Conservation:Against the backdrop of increasingly stringent environmental protection policies, VSI crusher will place greater emphasis on environmental protection and energy conservation. On the one hand, by improving VSI crusher's crushing technology and VSI crusher's structure, the dust emissions and noise pollution during the operation of VSI crusher are reduced. On the other hand, by adopting VSI crusher's high-efficiency motors and VSI crusher's transmission systems, VSI crusher's energy utilization rate is improved, achieving the goal of VSI crusher's energy conservation and VSI crusher's emission reduction.

3.VSI crusher's Automation and Intelligence:In the future, VSI Sand Making Machine will become more intelligent and automated. VSI Sand Making Machine will be equipped with more VSI Sand Making Machine's advanced sensors and VSI Sand Making Machine's control systems to achieve Vertical Shaft Impact Crusher's functions such as remote monitoring, fault diagnosis, and automatic maintenance of Vertical Shaft Impact Crusher. Operators can monitor Vertical Shaft Impact Crusher's running status of the Vertical Shaft Impact Sand Crusher anytime and anywhere through mobile phones or computers, promptly detect and solve problems of Vertical Shaft Impact Sand Crusher, and improve Vertical Shaft Impact Sand Crusher's running reliability and Vertical Shaft Impact Sand Crusher's management efficiency.

Application scenarios of VSI Vertical Shaft Impact Crusher

Vertical Shaft Impact Sand Crusher is widely used in construction, mining, road construction, concrete production and other fields. Vertical Shaft Impact Sand Crusher is particularly suitable for the production of high-quality aggregates and artificial sand. Vertical Shaft Impact Sand Crusher is also suitable for the fine crushing of metal and non-metallic ores, the treatment of metallurgical slag and the recycling of industrial waste. VSI Vertical Shaft Impact Crusher plays an important role in many industrial fields with Vertical Shaft Impact Sand Crusher's excellent finished particle shape and VSI Impact Crusher's efficient crushing capacity.

Our Service of VSI Vertical Shaft Impact Crusher

1. Customized Consultation of VSI Impact Crusher

Needs Assessment of VSI Impact Crusher: Our technical team will conduct in-depth communication with you to understand your project requirements, including daily output expectations, material characteristics, and application scenarios, so as to recommend the most suitable VSI Impact Crusher and configuration. Solution Design: For large-scale sand making plants, aggregate production lines or building materials processing projects, we can provide matching suggestions for the integration of the VSI Vertical Shaft Impact Crusher with your existing equipment, ensuring seamless connection and optimized overall production efficiency.

2. Professional Support of VSI Impact Crusher

Production Progress Tracking of VSI Impact Crusher: After order confirmation, we will regularly update you on the manufacturing progress of the equipment, including the production status and the estimated delivery time, keeping you fully informed.

3. Logistics & Packaging Guarantee of VSI Impact Crusher

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) to ensure it is delivered to your designated site intact and on time.

4. We provide technical documents of VSI Impact Crusher, including operation manuals, installation diagrams, and troubleshooting guides, which specify the equipment's working principle, operation steps, and common problem solutions for your reference.

Our Company

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+ m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mills, heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.