- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

Introduction of YA Series Circular Vibrating Screen

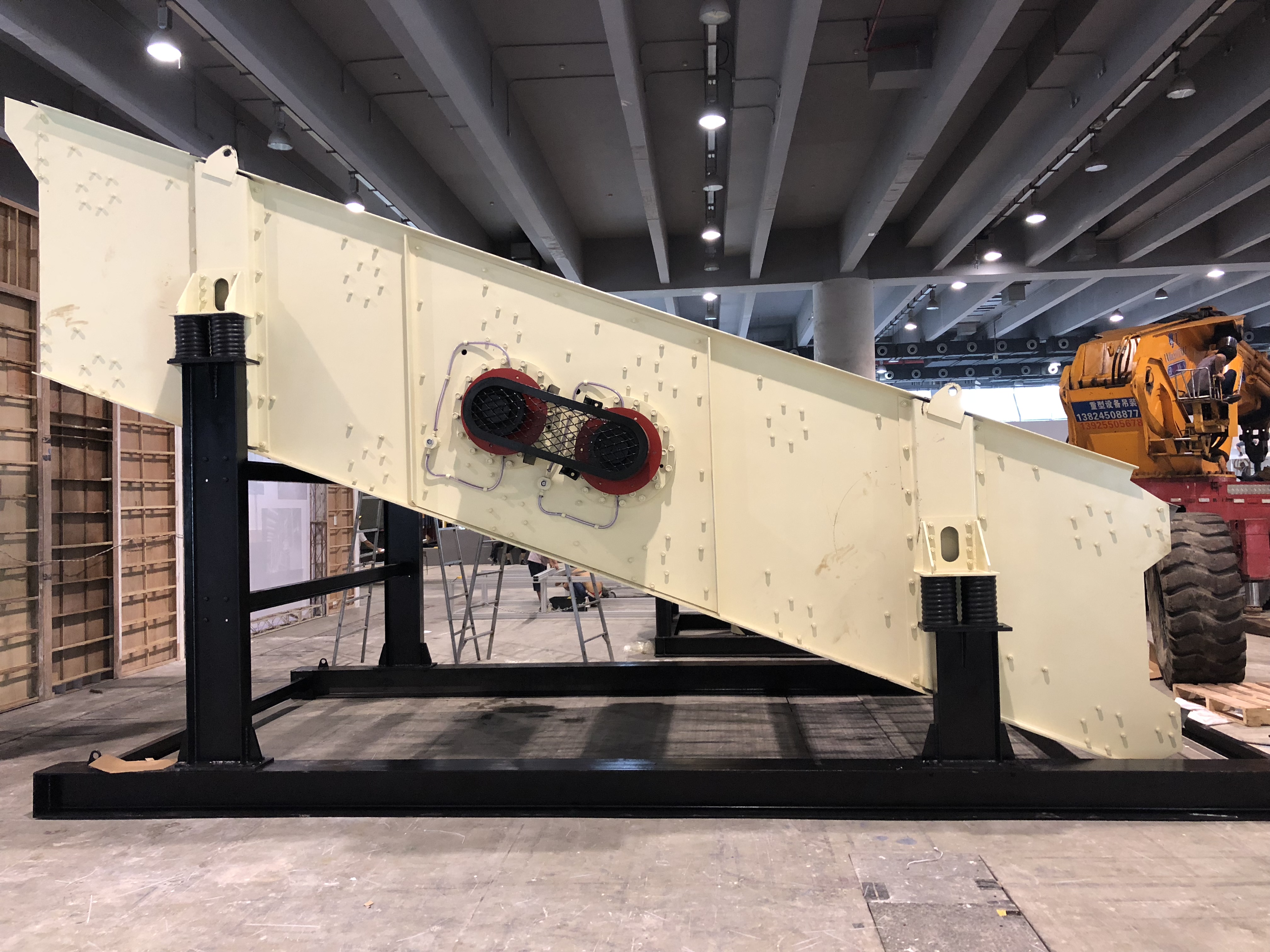

The YA vibrating screen machine mainly consists of a screen box, screen mesh, vibrator, vibration damping spring device, chassis, etc. A simplified eccentric shaft vibrator and eccentric block are used to adjust the amplitude. The vibrator is installed on the side plate of the screen box and is driven by a motor through a V-belt to generate centrifugal inertia force, forcing the screen box to vibrate.

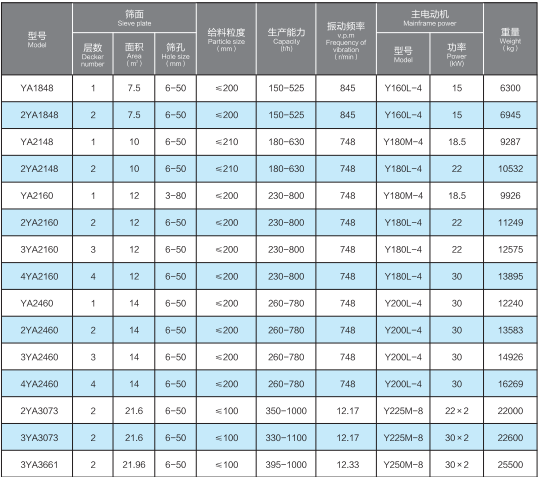

Technical Parameters of YA Series Circular Vibrating Screen

Advantages of YA Series Circular Vibrating Screen

1. High Processing Capacity: Owing to its advanced structural design and robust vibration performance, the YA vibrating screen is capable of handling large volumes of materials, boasting a high processing capacity. For example, in some large-scale coal screening plants, a single large-sized YA screen can process hundreds of tons of coal per hour, fully meeting the demands of large-scale production. The YA screen’s ability to manage substantial material flow efficiently makes it an ideal choice for industries requiring high throughput.

2. High-Precision Screening: By reasonably adjusting vibration parameters and screen mesh configurations, the YA screen achieves high-precision material screening. It can accurately separate materials of different particle sizes, satisfying the strict granularity requirements of various industrial productions. Take the construction materials industry as an example: where precise grading of sand and gravel aggregates is critical, the YA screen can accurately screen different specifications of sand and gravel, providing high-quality raw materials for concrete production and other applications. The screen’s precision ensures that even the most demanding particle separation tasks are executed with reliability.

3. Low Energy Consumption: The efficient operation of its vibrating motors and the rational structural design of the YA vibrating screen result in low energy consumption during operation. Compared with traditional screening equipment, the YA screen significantly reduces energy use, helping to cut production costs. For instance, in the screening operations of a large mine, employing the vibrating screen can save a substantial amount of electricity expenses annually. This energy-saving advantage makes the YA vibrating screen an environmentally friendly and economically viable choice for long-term operations.

4. Easy Maintenance: The YA vibrating screen features a relatively simple structure, with each component designed for easy installation, disassembly, and maintenance. Wearable parts such as screen meshes and vibrating motors can be replaced conveniently, minimizing equipment downtime and enhancing production efficiency. Additionally, the daily maintenance of the vibrating screen is straightforward—operators can master the key maintenance points after simple training. The vibrating screen’s user-friendly design ensures that routine upkeep and part replacements are carried out quickly, reducing operational interruptions and maximizing equipment availability.

Working principle of YA Series Circular Vibrating Screen

Vibration Generation

When the two vibrating motors of the YA vibrating screen rotate synchronously in opposite directions, the excitation forces generated by their eccentric blocks cancel each other out in the direction parallel to the motor axes. In the direction perpendicular to the motor axes, however, these forces combine into a resultant force that causes the screen box of the YA vibrating screen to vibrate vertically. Due to the specifically designed installation angle and position of the vibrating motors on the YA Screen, the screen box also acquires a horizontal vibration component, forming a complex elliptical motion trajectory. This unique motion pattern allows materials on the screen surface of the YA Circular Vibrating Screen to be fully loosened and thrown, significantly enhancing the screening effect by ensuring optimal particle separation.

Material Screening

Materials enter the screen box of the YA vibrating screen through the feed port and, under the action of vibration, quickly spread and move forward across the screen surface of the YA vibrating screen. Particles smaller than the screen mesh size pass through the mesh, falling to lower layers or being directly discharged as undersize products of the YA vibrating screen. Conversely, particles larger than the screen mesh size continue to move forward on the screen surface and are eventually discharged from the outlet as oversize products of the YA vibrating screen. Throughout the screening process of the YA vibrating screen, continuous vibration and throwing actions effectively reduce mutual particle extrusion and blockage, ensuring the YA vibrating screen operates with high efficiency and accuracy in separating materials by size.

Application scenarios of YA Series Circular Vibrating Screen

1. Mining Industry: The YA vibrating screen is widely used in the screening of various metal ores (such as iron ore, copper ore, and gold ore) and non-metal ores (such as limestone and dolomite). During mining operations, it classifies ores into appropriate particle sizes for subsequent crushing and grinding processes, helping improve ore dressing efficiency and product quality.

2. Coal Industry: In the coal sector, the YA vibrating screen is used to grade coal into different particle sizes to meet the needs of various users. For example, it separates coal into lump coal, fine coal, and other products for applications in thermal coal and coking coal. It also performs dehydration and medium separation screening for washed coal products in coal preparation plants.

3.Construction Materials Industry: In sand and gravel plants, the YA Series Circular Vibrating Screen screens sand and gravel to produce different specifications of construction sand and aggregates that meet the granularity requirements of construction projects. It also screens raw materials like cement and gypsum to ensure their particle sizes comply with production process standards.

4. Chemical Industry: The YA Series Circular Vibrating Screen is suitable for screening chemical raw materials, finished products, and semi-finished products, such as plastic pellets, fertilizer granules, and ore powders. By classifying materials by particle size, it helps improve the quality of chemical products and the stability of production processes. For example, in plastic manufacturing, screening plastic pellets with the YA Screen ensures uniform particle sizes, facilitating subsequent processing and molding.

Our Service of YA Circular Vibrating Screen

1. Customized Consultation of YA Circular Vibrating Screen

Needs Assessment: Our technical team communicates in-depth to clarify your requirements (daily output, material characteristics, screening precision) and recommend suitable models and screen mesh configurations.

Solution Design: Provide integration suggestions with existing equipment (feeders, conveyors, crushers) for large-scale production lines to ensure seamless connection and efficient operation.

2. Professional Support of YA Circular Vibrating Screen

Production Progress Tracking: Regularly update manufacturing progress of core components (screen box, vibrator, motor, screen mesh) and estimated delivery time after order confirmation.

3. Logistics & Packaging Guarantee of YA Circular Vibrating Screen

Cooperate with reliable international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) for on-time and intact delivery.

4. Technical Documentation Support of YA Circular Vibrating Screen

Provide operation manuals, installation diagrams, and troubleshooting guides, specifying working principles, operation steps, amplitude adjustment, and solutions to common issues (uneven screening, mesh blockage).