- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

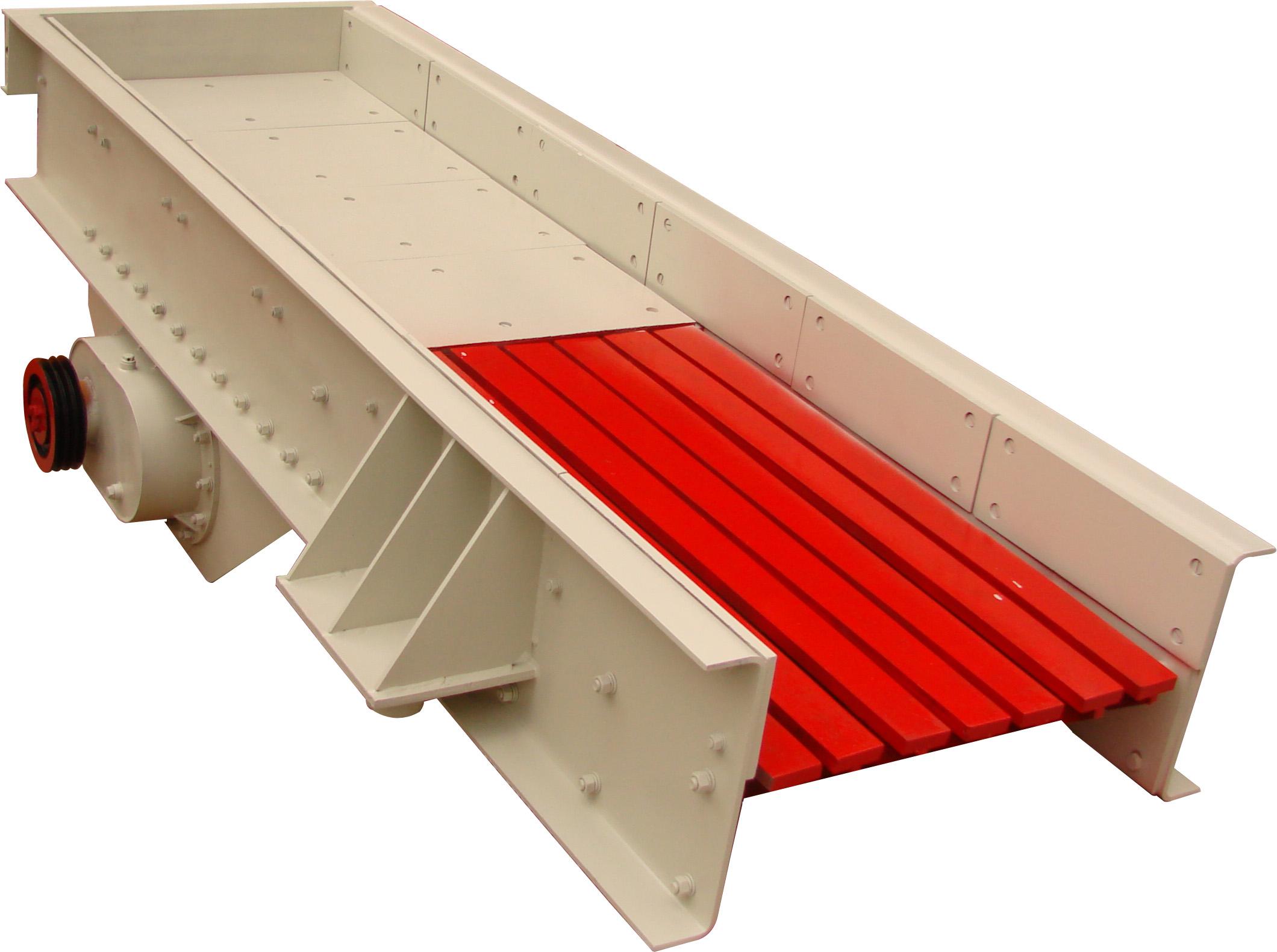

Introduction of ZSW Vibrating Feeder

In the production process, ZSW Feeder is used to feed block, granular and powder materials from the storage bin or hopper to the receiving equipment evenly, continuously or quantitatively; ZSW Feeder can feed to belt conveyors, bucket elevators, screening equipment, crushers, etc., and can be used for automatic batching, quantitative packaging, etc., and can be used in the process of automatic control to realize the automation of the production process.

Technial Parameters of ZSW Vibrating Feeder

| ZSW Vibrating Feeder | |||||||

Model | Max feeding size (mm) | Processing Capacity(t/h) | Motor power (kw) | Installation angle (°) | Total weight(t) | Trough size (mm) | Dimensions (L×W×H) (mm) |

| ZSW-380 x 95 | ≤500 | 100-160 | 11 | 0-10 | 4823 | 3800 x 960 | 3920 x 1640 x 1320 |

| ZSW-490x110 | ≤630 | 150-320 | 15 | 0-10 | 6647 | 4900x1100 | 4980 x 1830 x 1320 |

| ZSW-490x130 | ≤750 | 250-450 | 22 | 0-10 | 7200 | 4900x1300 | 4980 x 2580 x 2083 |

| ZSW-600x130 | ≤750 | 400-600 | 22 | 0-10 | 9250 | 6000x1300 | 6082 x 2580 x 2083 |

| ZSW-600x150 | ≤800 | 500-700 | 30 | 0-10 | 10190 | 6000x1500 | 6086 x 2662 x 1912 |

| ZSW-600x180 | ≤1200 | 550-1300 | 37 | 0-10 | 13750 | 6000x1800 | 6310 x 3262 x 2230 |

| ZSW-600x200 | ≤1500 | 850-1500 | 55 | 0-10 | 18000 | 6000x2000 | 6636 x 2761 x 2883 |

| Note: The above parameter table is for reference only, and the actual production capacity depends on the material type and production conditions | |||||||

Advantages of ZSW Feeder

1. Uniform & Stable Feeding of ZSW Vibrating Feeder

Achieves continuous, uniform feeding to avoid material accumulation and blockage, ensuring stable operation of downstream equipment. This significantly improves production efficiency and end-product quality, serving as a reliable foundation for smooth production in mining crushing lines, construction material processing systems, and more.

2. Strong Adaptability of ZSW Feeder

Excels in handling diverse materials and particle sizes—from large lumpy ores to fine granular sands and powders. ZSW Feeder tolerates high moisture and viscosity, maintaining consistent performance in challenging scenarios like wet coal handling and sticky clay processing.

3. Reliable Operation & Easy Maintenance of ZSW Feeder

Boasts a simple structure with minimal moving parts, reducing malfunction risks. Routine checks and part replacements are straightforward. High-quality key components (e.g., motors) manufactured with advanced processes ensure long-term, heavy-duty stable operation, critical for cost-sensitive industries like metallurgy and mining where downtime is costly.

4. Energy-Efficient & Eco-Friendly of ZSW Feeder

Features low-power motors that generate optimal feeding force, operating with minimal noise to meet environmental regulations. Uniform feeding reduces material waste and excessive crushing, lowering production costs and aligning with sustainability goals.

Working principle of ZSW Feeder

The ZSW Vibrating Feeder mainly consists of a motor, exciter, springs, and a feeder trough. The motor generates exciting force, which is transmitted to the trough via the exciter to produce periodic vibrations. When materials are placed in the trough, they move forward in a parabolic trajectory under the action of vibrations, realizing uniform and continuous feeding to downstream equipment. ZSW Feeder's optimized design leverages mechanical vibrations to ensure efficient material conveyance and stable feeding performance in various industrial scenarios.

Structural Features of ZSW Vibrating Feeder

1. Sturdy & Durable Construction of ZSW Feeder

The feeder trough is welded from high-strength steel plates, delivering excellent rigidity and wear resistance. ZSW Feeder withstands strong impacts from hard ores and operates stably for long periods in harsh environments (e.g., dusty mines, humid underground settings), ensuring an extended service life.

2. Advanced Vibration Excitation Device of ZSW Feeder

Equipped with high-performance vibration motors or adjustable-force exciters, ZSW Feeder supports precise tuning of vibration parameters. This allows adaptation to different material types (blocky, powdery) and feeding demands (speed, volume), guaranteeing stable and accurate feeding for downstream processes.

3. Flexible Spring System of ZSW Feeder

High-quality springs serve as elastic components, providing good elasticity and shock absorption. The system supports the trough weight to maintain vibration stability, reduces vibration impact on the foundation, and enables installation on various base types without excessive environmental interference. ZSW Feeder also stabilizes vibration frequency and amplitude to enhance feeding uniformity.

4. Convenient Adjustment Mechanism of ZSW Feeder

A dedicated feeding volume adjustment device enables stepless control by tuning the vibration motor’s eccentric block angle or converter frequency. This meets varying feeding requirements across different production processes, boosting of ZSW Feeder's versatility and adaptability.

1. What is the main function of the ZSW Vibrating Feeder?

ZSW Feeder is designed to feed block, granular, and powder materials from storage bins or hoppers to downstream equipment (e.g., belt conveyors, crushers, screening machines) in an even, continuous, or quantitative manner. ZSW Feeder also supports automatic batching, quantitative packaging, and integration into automated production control systems.

2. What factors affect the actual processing capacity of the ZSW Vibrating Feeder?

The actual capacity is not fixed and depends on the type of material being handled (hardness, humidity, particle size) and specific production conditions. The listed parameters in the technical table are for reference only.

3. Can the ZSW Vibrating Feeder handle different types of materials?

Yes. ZSW Feeder has strong adaptability and can efficiently feed large lumpy ores, granular sands, and fine powdery materials. ZSW Feeder also tolerates materials with high moisture and viscosity, performing stably in scenarios like wet coal handling and sticky clay processing.

4. How does the ZSW Vibrating Feeder achieve uniform feeding?

ZSW Feeder relies on its working principle: the motor generates exciting force, which is transmitted to the trough via the exciter to produce periodic vibrations. Materials in the trough move forward in a parabolic trajectory, ensuring continuous and uniform feeding to downstream equipment.

5. Is the ZSW Vibrating Feeder easy to maintain?

Yes. ZSW Feeder features a simple structure with minimal moving parts, which reduces the risk of malfunctions. Routine checks and part replacements can be done easily by operators, and ZSW Feeder's high-quality key components (e.g., motors) are built to withstand long-term heavy-duty operation.

6. Can the feeding volume of the ZSW Vibrating Feeder be adjusted?

Yes. ZSW Feeder is equipped with a convenient adjustment mechanism. Operators can achieve stepless control of feeding volume by adjusting the eccentric block angle of the vibration motor or the frequency of the converter, adapting to different production process requirements.

7. What makes the ZSW Vibrating Feeder suitable for harsh working environments?

ZSW Feeder's feeder trough is welded from high-strength steel plates, providing excellent rigidity and wear resistance. ZSW Feeder can withstand strong impacts from hard ores and operate stably in dusty mines, humid underground settings, and other harsh conditions for an extended service life.

8. Will the ZSW Vibrating Feeder cause excessive vibration interference to the installation foundation?

No. ZSW Feeder adopts a flexible spring system that serves as an elastic component with good shock absorption performance. The system reduces the impact of vibration on the foundation, allowing installation on various base types without causing excessive environmental interference.

Shenyang Dapeng is a leading Chinese manufacturer in the crusher industry, integrating R&D, design, manufacturing, and pre-sales/after-sales services for crushing and mineral processing machinery.

With over 200 employees (including 30+ senior/middle technical personnel) and a 35,000+ m² standardized workshop, our products are widely used in mining, cement, highway, power, metallurgy, and other industries.

Core offerings include: rotary crushers, European-style jaw crushers, DPCS/DPCH/DPHP hydraulic cone crushers, PYS Symons cone crushers, VSI crushers, ball mills, heavy apron feeders, vibrating feeders, and vibrating screens. We also supply premium OEM-compatible parts for popular brands (e.g., Metso HP series, Sandvik CH/CS cone crushers).

Adhering to the principles of "leading technology, reliable quality, reasonable pricing, and thoughtful service" and the enterprise spirit of "professionalism, efficiency, and pragmatism," we strive for customer satisfaction. We warmly welcome domestic and foreign clients to visit, consult, and cooperate with us.