Introduction to Equipment Configuration and Capacity of African Granite Sandstone Aggregate Production Line

In a vast expanse of the African continent, there lies a large - scale and technologically advanced sand and gravel aggregate production line. This particular region within the African continent is richly endowed with granite resources. These granites, being characteristically hard and wear - resistant, serve as high - quality building materials.

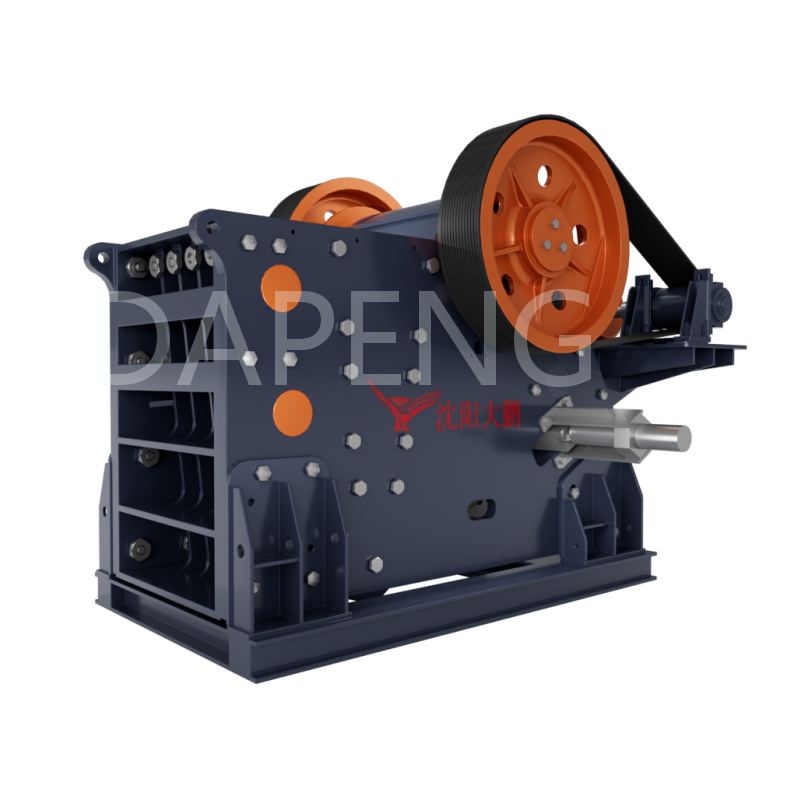

The C125 jaw crusher, an indispensable and prominent piece of equipment on this production line, takes center stage in processing these abundant African granite resources. The C125 jaw crusher, with its robust construction and powerful crushing mechanism, is specifically designed to handle the tough African granite. It is the C125 jaw crusher that initiates the crucial transformation of large granite chunks into smaller, more manageable pieces. This initial crushing action by the C125 jaw crusher is fundamental as it paves the way for all subsequent operations in the production line. Without the reliable performance of the C125 jaw crusher, efficiently processing the vast amounts of African granite resources would be a daunting task. The C125 jaw crusher, in this African production setup, is truly the workhorse that drives the initial stage of turning these valuable granite resources into useful sand and gravel aggregates.

One of the core pieces of equipment on this production line located in Africa is the C125 jaw crusher. The C125 jaw crusher, an indispensable component in the overall setup, plays a crucial role in the entire production process. Acting as the “vanguard” of the production line, this C125 jaw crusher undertakes the critical task of the initial crushing of granite raw materials at the African production site. The C125 jaw crusher's powerful crushing capacity is truly remarkable, with an hourly output of up to 500 tons. This implies that within an hour, the C125 jaw crusher can efficiently process a large amount of granite material, providing a sufficient and stable raw material supply for the subsequent production processes on the African continent. Thanks to the C125 jaw crusher's performance, the African production line can operate smoothly.

The sand and gravel materials processed by this African production line, which heavily rely on the work of the C125 jaw crusher in the initial stages, have various particle size specifications, covering different ranges from zero to 31.5 millimeters, specifically divided into four intervals. Among them, materials from zero to five millimeters are called fine sand. The C125 jaw crusher starts the process that eventually leads to the creation of these different - sized materials. The fine sand, which usually has good particle size uniformity and small particle size, is often used in the construction industry for concrete preparation. This process, which is enabled by the initial work of the C125 jaw crusher in breaking down the granite, can effectively fill the gaps in concrete, improving the compactness and strength of concrete.

Materials with a thickness of five to ten millimeters belong to the category of medium sand, which is also widely used in construction. For example, in some projects that require high mortar performance, medium sand can provide better bonding performance, making the connection between building materials tighter. The C125 jaw crusher is the starting point of the journey that results in the African production of this medium sand, as it begins the breakdown of the raw granite into materials that can be further processed into the desired sizes.

Materials with a diameter of ten to twenty millimeters are called coarse sand, and their relatively large particle size allows them to serve as a skeleton support in building structures, helping to enhance the overall stability and load - bearing capacity of the building. Once again, the C125 jaw crusher kicks off the series of operations that ultimately yield this coarse sand, by initially crushing the granite raw materials.

And materials ranging from 20 to 31.5 millimeters belong to small stones, which hold significant application value in diverse African projects, especially in road paving and water conservancy undertakings across the African continent. In the context of African highway construction, these small stones are of utmost importance. They can be utilized as base materials, playing a crucial role in providing a solid foundation for the road surface. This application is essential for guaranteeing the durability and stability of African roads, which are vital for the seamless movement of people and goods within African countries, facilitating economic growth and regional connectivity in Africa.

Through such a scientifically reasonable equipment configuration, the granite sand and gravel aggregate production line in this specific African region, tailored to the unique geological and demand characteristics of African countries, is capable of precisely producing sand and gravel materials of different particle sizes. This production line, which is a crucial part of our contribution to African industrial development, can effectively meet the demand for sand and gravel aggregates in multiple fields across the African continent, such as construction and infrastructure. It serves as a powerful engine for African local economic development and engineering construction, benefiting various African communities and promoting progress in African infrastructure projects.