1. Installation and Test Run to Keep Machine Protected

To ensure the machine is optimally protected right from the get - go, it should be installed on a perfectly horizontal concrete foundation and securely fixed with anchor bolts. After installation, an equipment test run is a must. This initial step is of utmost importance as a proper installation paves the way for the machine's stable operation, minimizing the risk of mechanical failures stemming from improper setup. A well - installed machine is far less likely to experience issues during its lifespan, thus playing a fundamental role in keeping the machine protected over the long haul. By adhering to these installation and test - run procedures, we are actively taking measures to ensure the machine remains in a machine protected state from the start of its operational life.

2. Lubrication Maintenance to Keep Machine Protected

The bearing shoulders the entire load of the machine. Good lubrication is highly correlated with the bearing life, which in turn directly impacts the machine's service life and working efficiency. By guaranteeing that the injected lubricating oil is clean and the seal is in excellent condition, we are taking a major stride towards keeping the machine protected. The main oiling points of this machine include: (1) rolling bearings; (2) roller bearings; (3) all gears; (4) movable bearings and sliding surfaces. Regular and proper lubrication at these points helps to minimize friction, prevent excessive wear, and is thus a key element in how the machine protected. Adequate lubrication not only extends the lifespan of components but also ensures smooth operation, which is crucial for the overall protection of the machine. Consistent lubrication maintenance routines are essential for maintaining the machine in a protected state, safeguarding it from premature wear and tear.

3. Component Inspection to Keep Machine Protected

3.1 Wheel Hoops

For new equipment, the wheel hoops are prone to loosening. Frequent checks are necessary to keep the machine protected. Loose wheel hoops can cause vibrations and uneven stress distribution in the machine, potentially leading to component damage. By detecting and tightening loose wheel hoops in a timely manner, we can safeguard the normal operation of the machine and ensure it remains protected. Regular inspections of wheel hoops are a straightforward yet highly effective way to prevent potential problems and keep the machine in a protected condition. These checks should be part of a regular maintenance schedule to continuously keep the machine protected from issues related to loose wheel hoops.

3.2 Operational Condition

Pay close attention to whether the operation of each part of the machine is normal. Listen for any abnormal sounds. Unusual noises, such as knocking or grinding, may indicate internal problems, such as misaligned parts or worn - out components. In case of any abnormal situation, especially in the case of the gyratory crusher, if there is an abnormal knocking sound inside the crusher, stop the operation immediately. This is an important part of protecting the machine from further damage. By being vigilant about the operational condition, we can better understand how to keep the machine protected. Monitoring the operational condition continuously allows for early detection of issues, which is fundamental to protecting the machine. Regular visual and auditory inspections are key to maintaining the machine in a protected state, catching any potential problems before they escalate.

3.3 Wear - Prone Parts

Monitor the wear degree of easily worn parts and replace them promptly. Worn - out parts, if left unaddressed, can not only affect the machine's performance but also cause damage to other related components. For example, in a crusher, worn - out crushing teeth can lead to inefficient crushing and increased stress on the drive system. Regularly checking and replacing these wear - prone parts is a fundamental way to keep the machine protected. Timely replacement of worn - out parts is crucial for maintaining the machine's performance and ensuring it stays protected. A system for tracking the wear of these parts and scheduling replacements is essential for the ongoing protection of the machine.

4. Gyratory Crusher - Specific Protection Measures to Keep Machine Protected

4.1 Feed Control

For a gyratory crusher, the feed particle size shall not be greater than 0.8 times of the feed port. Exceeding this limit can cause overloading of the crusher, leading to excessive wear on components or even mechanical failures. Also, ensure that the discharge chute and the lower part of the crushing cone are not blocked by ore. Blockages can cause the ore to be lifted by the crushing cone, and mineral powder may enter the eccentric shaft, resulting in serious accidents. By controlling the feed properly, we are effectively protecting the gyratory crusher. This is a crucial aspect of how the machine is protected in the context of a gyratory crusher operation. Adhering to the correct feed control parameters is essential for protecting the gyratory crusher from premature wear and potential breakdowns. Consistent monitoring of the feed process is necessary to keep the gyratory crusher in a protected state during operation.

4.2 Discharge Port Adjustment and Overload Insurance

4.2.1 Mechanical Method

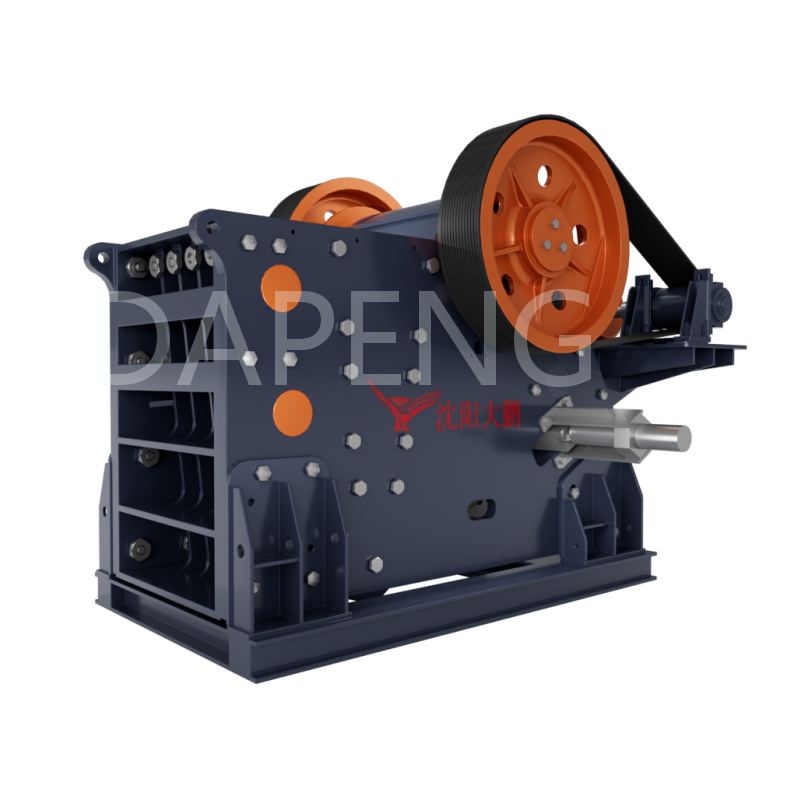

There are two methods to complete the adjustment of the discharge port and overload insurance. In the mechanical method, there is an adjusting nut on the upper end of the main shaft. By rotating the adjusting nut, the crushing cone can be lowered or raised, thereby changing the size of the discharge port. When overloaded, the insurance is achieved by cutting off the safety pin on the drive pulley. This mechanism protects the machine from severe damage due to overloading. It is an important part of the overall system that keeps the machine protected in case of mechanical overload situations. The mechanical overload protection mechanism acts as a safeguard, ensuring the machine is protected from excessive stress during overloading events. Regular inspection of this mechanical protection system is also important to ensure it functions properly and keeps the machine protected at all times.

4.2.2 Hydraulic Method

In a hydraulic gyratory crusher, the main shaft is located on the plunger in the hydraulic cylinder. The upper and lower positions of the crushing cone can be adjusted by changing the volume of hydraulic oil under the plunger, which in turn changes the size of the discharge port. When overloaded, the downward pressure of the main shaft increases, forcing the hydraulic oil under the plunger to enter the accumulator in the hydraulic transmission system. This causes the crushing cone to drop, increasing the discharge port to discharge non - crushed objects (such as ironware and wood blocks) that enter the crushing chamber with the material, thus completing the insurance function and machine protected from damage.