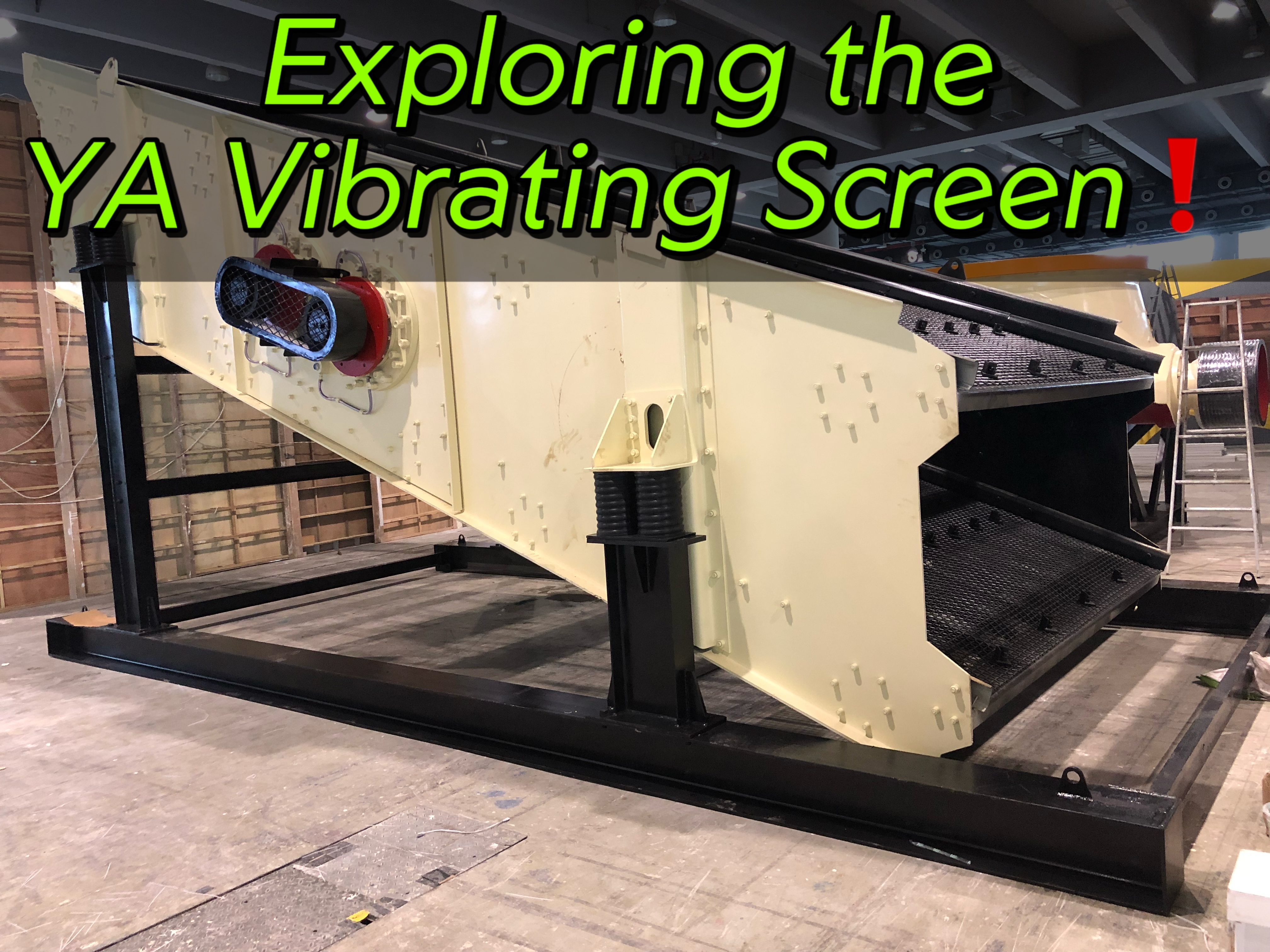

In the modern industrial chain, especially in the mining, construction materials and chemical sectors, material classification is a crucial link that directly affects production efficiency and product quality. As a core component of this Mining screening equipment, the YA Vibrating Screen has won widespread recognition for YA vibrating screen's outstanding high-precision screening performance and excellent energy-saving advantages. This article will delve into the technical secrets behind the YA Vibrating Screen, revealing how this Mining screening equipment achieves efficient balance between high-precision material classification and low energy consumption, and why this Mining screening equipment has become an indispensable part of high-quality mining equipment supporting systems.

The high-precision screening capability of the YA Vibrating Screen stems from YA vibrating screen's sophisticated structural design and scientific vibration principle. Unlike traditional mining screening equipment, the YA Vibrating Screen adopts a simplified eccentric shaft vibrator and eccentric block amplitude adjustment mechanism. When the two vibrating motors rotate synchronously in opposite directions, the excitation forces cancel each other in the direction parallel to the motor axis and form a combined force in the vertical direction. With the specially designed installation angle of the motors, the screen box forms a precise elliptical motion trajectory. This unique motion mode enables materials on the screen surface to be fully loosened and thrown, effectively reducing particle extrusion and screen hole blockage, and ensuring that particles of different sizes are accurately separated. For mining screening equipment systems that require strict material grading, such as ore dressing lines, YA Vibrating Screen can be equipped with different screen mesh configurations according to actual needs, accurately classifying metal ores such as iron ore and copper ore, and non-metal ores such as limestone and dolomite, laying a solid foundation for subsequent crushing and beneficiation processes.

In terms of energy consumption control, the YA Vibrating Screen has achieved a leap forward in energy efficiency through optimized structural design and efficient component configuration, setting a new benchmark for energy-saving performance in mining screening equipment. On the one hand, the YA Circular Vibrating Screen adopts high-efficiency vibrating motors and reasonable structural layout, which significantly reduces energy loss during operation. Compared with traditional mining screening equipment, the energy consumption of the YA Circular Vibrating Screen is reduced by a considerable margin, helping enterprises save a lot of electricity costs in long-term operations. On the other hand, the rational design of the vibration damping spring device of the YA Circular Vibrating Screen not only reduces the impact of equipment operation on the foundation, but also further improves energy utilization efficiency by reducing useless work consumption. In large-scale mining operations, where mining equipment needs to operate continuously for a long time, the low-energy-consumption advantage of the YA Circular Vibrating Screen is particularly prominent, which can effectively reduce the overall operation cost of the production line while ensuring production capacity.

As an important part of mining equipment, the YA Circular Vibrating Screen also has the characteristics of strong adaptability and easy maintenance, which further enhances this Mining screening equipment's application value in various industrial scenarios. Whether in the high-dust mining environment or the humid coal preparation plant, the YA Circular Vibrating Screen can maintain stable operation. Its wear parts such as screen mesh and vibrating motor are easy to replace, minimizing equipment downtime and ensuring the continuity of the mining equipment production line. In addition, the YA Circular Vibrating Screen can be seamlessly integrated with other mining equipment such as feeders, conveyors and crushers, forming a streamlined material processing system, which further improves the overall production efficiency of the enterprise.

In the context of the global emphasis on energy conservation and emission reduction and the continuous upgrading of industrial production requirements, the YA Circular Vibrating Screen, as a high-performance mining equipment, has become an important choice for enterprises to improve product quality and reduce operation costs. This Mining screening equipments high-precision screening technology ensures the stability of product quality, while its low-energy-consumption advantage conforms to the development trend of green and low-carbon industry. With the continuous advancement of industrial intelligence, YA Circular Vibrating Screen will continue to undergo technological iterations, bringing more efficient and energy-saving solutions to the mining equipment field and injecting strong impetus into the high-quality development of various industries.

this Mining screening equipment is not difficult to see that the YA Circular Vibrating Screen has achieved a perfect combination of high precision and low energy consumption through scientific structural design and advanced vibration principle. As a key mining equipment, YA Vibrating Screen will continue to play an important role in the global industrial production field, helping enterprises achieve more efficient, environmentally friendly and high-quality production.