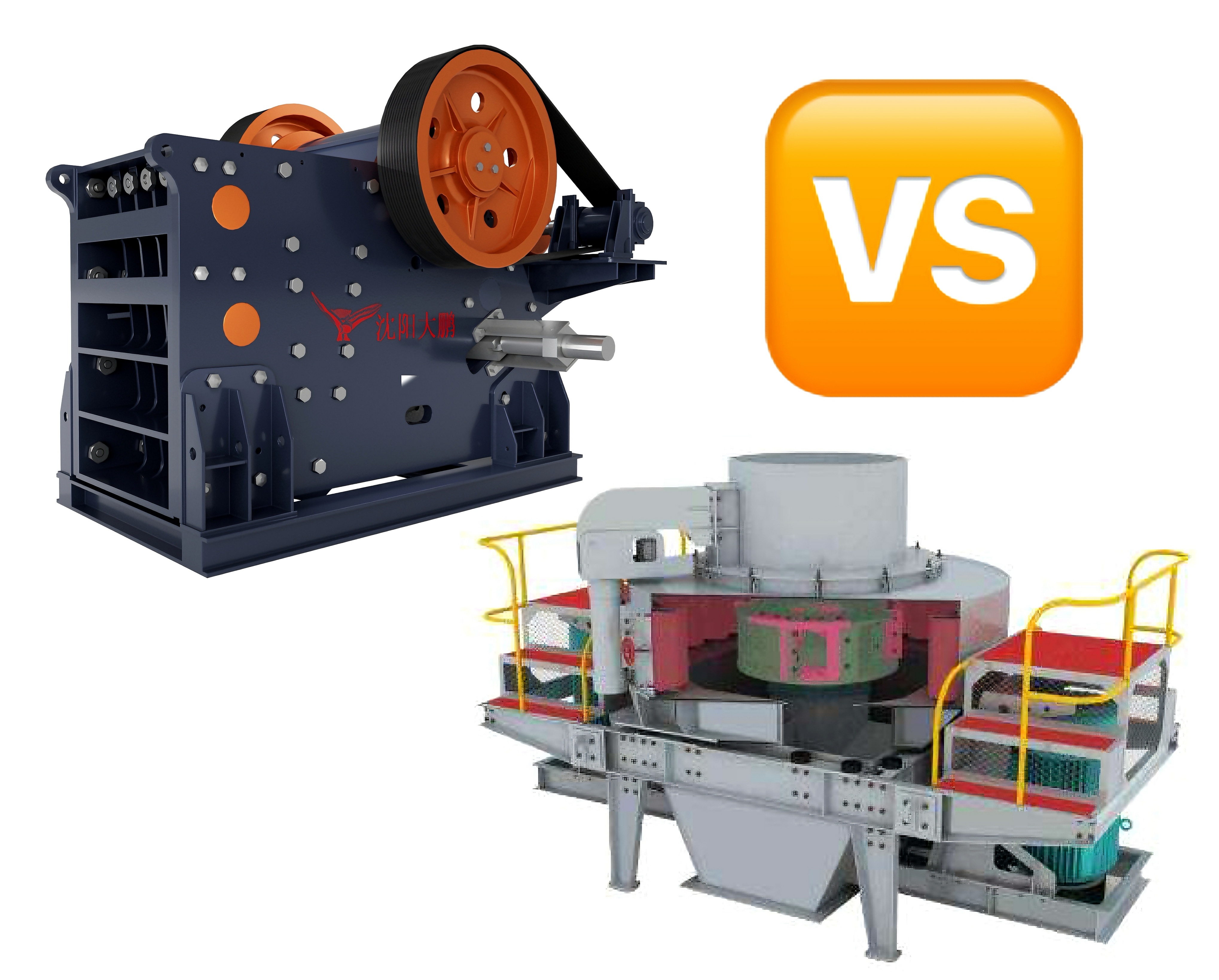

Jaw Crusher (primary crushing equipment) vs. Impact Crusher sand-making and shaping equipment:

How to Choose?

The Ultimate Guide to Mining Crushing Equipment Selection

In sand and aggregate production, mining, and other engineering projects, Jaw crusher (primary crushing equipment) and impact crusher (VSI Crusher) are the core crushing equipment. The selection of these two directly determines the efficiency of the production line and the quality of finished products. And VSI Crusher (Vertical Shaft Impact Crusher), as a high-end sand-making and shaping equipment, is often used in conjunction with the former two to form a complete process of "primary crushing → secondary crushing/shaping → sand making". This article will explain the selection logic of Jaw crusher, impact crusher and VSI Crusher (sand-making and shaping equipment) from four dimensions: core functions, applicable materials, discharge characteristics, and scenario adaptation, helping enterprises accurately match production needs.

Core Functions: Jaw Crusher (primary crushing equipment) Focuses on Primary Crushing, Impact Crusher (VSI Crusher) (sand-making and shaping equipment) Specializes in Secondary Crushing and Shaping

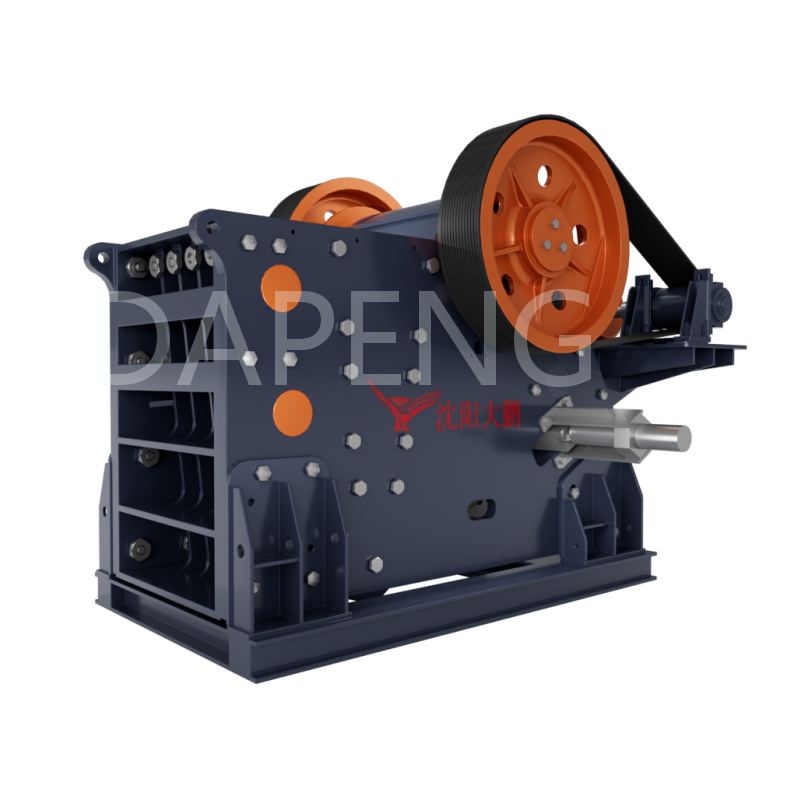

Jaw crusher (primary crushing equipment) takes primary crushing as its core function and is the "first line of defense" in the crushing production line. Through the extrusion effect of the moving jaw and the fixed jaw, it can efficiently process large pieces of raw ore, crushing rocks with a particle size of more than 1 meter to 80-150mm, providing qualified raw materials for subsequent processes. Whether it is a small quarry or a large production line with a capacity of 500 tons per hour, Jaw crusher has become a must-have equipment due to its stable primary crushing performance. Some high-performance Jaw crushers can also take into account secondary crushing operations to adapt to multi-stage crushing needs.

Impact crusher (VSI Crusher) (sand-making and shaping equipment) focuses on the dual functions of secondary crushing and shaping, undertaking the primary crushing products of Jaw crusher for further processing. It drives materials to impact the impact plate through a high-speed rotating rotor to achieve multi-stage crushing. It can not only refine materials to 20-50mm but also optimize the particle shape, making the finished products more in line with the standards of construction aggregates. In the sand-making production line matched with VSI Crusher, the secondary crushing and shaping effect of impact crusher (sand-making and shaping equipment) directly affects the sand-making efficiency of VSI Crusher. The three work together to greatly improve the output quality of the entire production line.

Applicable Materials: Jaw Crusher Is Wear-Resistant and Universal for Hard Rocks, Impact Crusher (VSI Crusher) is Suitable for Medium and Soft Rocks

The core advantage of Jaw crusher lies in its wear resistance and universality. Whether it is hard rocks such as granite and basalt, or medium and soft rocks such as limestone and dolomite, Jaw crusher can crush stably without problems such as overload or rapid wear of vulnerable parts. Its jaw plates are made of composite materials of high-chromium alloy and wear-resistant steel.

Impact crusher (VSI Crusher) is more suitable for processing materials with medium and low hardness and high brittleness, such as limestone, gangue, shale, etc. Such materials are easy to form cubic particles during impact crushing, which can give full play to the shaping advantages of impact crusher (sand-making and shaping equipment). If impact crusher is used to process hard rocks, it will lead to rapid loss of vulnerable parts such as blow bars, which not only increases operating costs but also affects production continuity. At this time, it is necessary to complete primary crushing with Jaw crusher (primary crushing equipment) first, and then match it with VSI Crusher for sand making, instead of relying on impact crusher (VSI Crusher) to process hard rock materials.

Discharge Characteristics: Jaw Crusher (primary crushing equipment) Discharges Blocky Materials, Impact Crusher (VSI Crusher) Produces More Round Particle Shapes

Affected by the extrusion crushing principle, the discharge of Jaw crusher (primary crushing equipment) is mainly blocky, with a relatively high proportion of needle-shaped and flaky particles, and the particle shape regularity is relatively limited. Although such primary crushing products are not suitable for direct use as high-end aggregates, they exactly meet the feeding requirements of impact crusher (sand-making and shaping equipment), forming a perfect connection of "primary crushing → refinement and shaping". High-quality Jaw crushers can reduce the proportion of large materials and make the discharge particle size more uniform by optimizing the design of the crushing chamber, reducing the burden of subsequent processing of impact crusher (VSI Crusher).

VSI Crusher for sand making without additional treatment. Compared with the blocky discharge of Jaw crusher (primary crushing equipment), the shaping effect of impact crusher (VSI Crusher) can significantly increase the added value of finished products, especially suitable for the aggregate needs of high-standard projects such as expressways and high-speed railways.

Scenario Recommendations: Choose Jaw Crusher for Primary Crushing in Quarries, Match Impact Crusher + VSI Crusher for Aggregate Shaping

In the primary crushing link of quarries, Jaw crusher (primary crushing equipment) is an irreplaceable choice. Whether it is dealing with hard rock mines such as granite and basalt, or limestone quarries, Jaw crusher can meet the demand with large processing capacity and strong impact resistance, with a single-machine hourly output of 200-500 tons, perfectly matching the production capacity requirements of medium and large production lines. For example, the 500-ton-per-hour limestone production line in Guizhou uses the PE1050 Jaw crusher as the core of primary crushing, laying the foundation for the subsequent impact crusher and VSI Crusher.

For scenarios such as construction aggregate shaping and manufactured sand production, the combination of impact crusher and VSI Crusher is more advantageous. After Jaw crusher (primary crushing equipment) completes primary crushing, impact crusher performs secondary crushing and shaping on the materials, and then VSI Crusher carries out efficient sand making through the "rock-on-rock" principle, finally producing manufactured sand with excellent particle shape and reasonable gradation. This classic configuration of "Jaw crusher + impact crusher + VSI Crusher" is widely used in commercial concrete mixing stations, expressway construction and other fields, which can not only ensure production capacity but also meet the demand for high-quality aggregates.

If an enterprise only needs primary crushing products for low-standard scenarios such as subgrade backfilling, it is sufficient to configure Jaw crusher (primary crushing equipment) alone; if it pursues high-end aggregates or manufactured sand output, it is necessary to take Jaw crusher as the core of primary crushing, and match it with impact crusher for shaping and VSI Crusher for sand making to build a full-process crushing and sand making system.