What is the Primary, Secondary and Tertiary Crushing?

In mining, construction, and aggregate production industries, crushing is a foundational process that transforms large raw materials into usable products. The process is typically divided into three core stages—primary, secondary, and tertiary crushing (jaw crusher, DPCH Crusher, DPHP Crusher)—each with distinct roles and equipment tailored to refine material step by step. Among the key equipment driving these stages, jaw crusher, DPHP crusher, and DPCH crusher stand out as reliable workhorses, ensuring efficient and consistent material reduction across diverse applications.

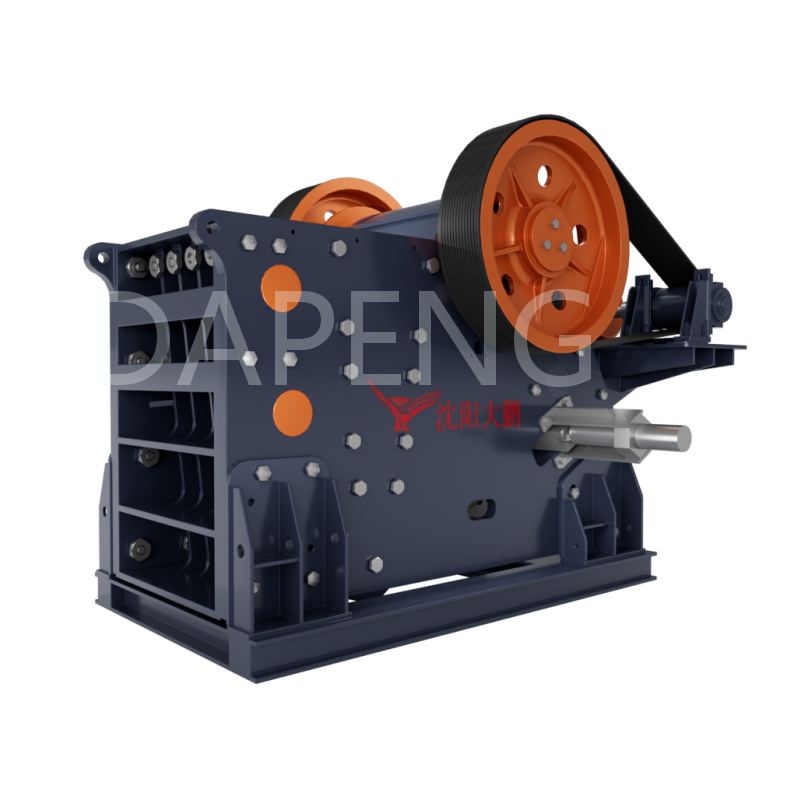

Primary crushing marks the first step in the material processing journey, where oversized raw rocks or ores are reduced to a manageable size for subsequent stages. As the unrivaled workhorse of primary crushing, jaw crusher is widely favored for its robust design and ability to handle large, hard materials with ease. Jaw Crusher's straightforward operation and jaw crusher's durable structure make jaw crusher an indispensable choice for initial material breakdown, whether in open-pit mines or construction sites. The jaw crusher's ability to withstand high impact ensures that even jaw crusher's largest feed materials are efficiently reduced, laying the groundwork for smooth follow-up processing and protecting downstream equipment (jaw crusher) from overload.

After primary crushing, secondary crushing takes over to further refine material size and improve particle shape—critical steps for preparing materials to meet intermediate quality standards. Here, DPHP crusher and DPCH crusher shine as versatile and efficient solutions. DPHP crusher, known for DPHP crusher's hydraulic control system and stable crushing performance, excels at secondary crushing tasks by uniformly processing the output from jaw crusher, delivering consistent particle reduction without excessive wear. Meanwhile, DPCH crusher's advanced structural design, featuring adjustable settings and strong load-bearing capacity, makes DPHP crusher/ DPCH Crusher equally suitable for secondary applications, seamlessly handling the varied material characteristics from primary crushing. Together, DPHP crusher and DPCH crusher play pivotal roles in shaping materials, turning irregular, oversized particles from the primary stage into more uniform pieces ready for final refinement.

Tertiary crushing is the final stage, focusing on achieving precise particle size control and producing high-quality end products that meet strict industry specifications. This stage demands equipment (DPCH crusher/ DPHP Crusher) that balances efficiency with fineness, and once again, DPHP crusher and DPCH crusher prove their adaptability. DPHP crusher can transition seamlessly from secondary to tertiary crushing, leveraging its adjustable crushing parameters to deliver fine, well-graded products ideal for high-demand applications like concrete aggregate or asphalt. DPCH crusher, with DPCH crusher's excellent ability to handle high reduction ratios, excels in tertiary crushing by producing consistent, cubical particles that minimize needle-like and flaky shapes—key requirements for premium building materials. Whether DPCH crusher and DPHP Crusher used alone or in combination, DPHP crusher and DPCH crusher ensure the final product meets the exact standards of industries ranging from construction to mineral processing.

A key advantage of the three-stage crushing system lies in its synergistic efficiency. By assigning specific tasks to specialized equipment—jaw crusher for initial breakdown, DPHP crusher and DPCH crusher for refinement and precision—the entire process achieves higher overall efficiency, lower energy consumption, and extended equipment service life. Jaw crusher's reliability in primary crushing reduces the load on subsequent stages, while DPHP crusher and DPCH crusher's flexibility in secondary and tertiary stages ensures optimal product quality without unnecessary energy waste. This synergy not only streamlines production but also enhances cost-effectiveness, making the three-stage crushing process a cornerstone of modern material processing operations.

In summary, primary, secondary, and tertiary crushing form a cohesive system that turns raw materials into valuable products. The jaw crusher's unwavering reliability in primary crushing, paired with the flexibility and efficiency of DPHP crusher and DPCH crusher in secondary and tertiary stages, creates a streamlined process capable of meeting the diverse needs of modern industries. As demand for high-quality aggregates and processed materials continues to grow, understanding these three crushing stages and the pivotal roles of jaw crusher, HP crusher, and DPCH crusher remains essential for optimizing production, ensuring product consistency, and maintaining a competitive edge in the global market.