- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

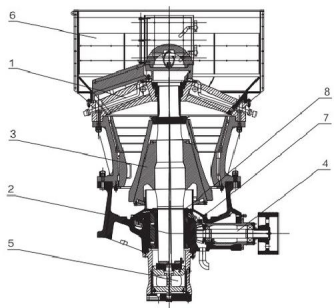

Diagram of DPCH Single Cylinder Hydraulic Cone Crusher (DPCH Cone Crusher)

1. Upper frame 2. Lower frame 3. Broken cone

4. Driving part 5. Hydraulic cylinder 6. Feeding device

7. Eccentric sleeve 8. Sealing part

Introduction of DPCH Single Cylinder Hydraulic Cone Crusher (DPCH Cone Crusher)

Produced by Shenyang Dapeng Heavy Equipment, the DPCH Single Cylinder Hydraulic Cone Crusher (CH Crusher) achieves internationally leading technical standards with full intelligent control. DPCH Single Cylinder Cone Crusher's (DPCH Cone Crusher) optimized structure allows easy discharge opening adjustment—even during operation—while the intelligent system of DPCH Single Cylinder Cone Crusher's (DPCH Cone Crusher) maintains optimal working conditions and automatically compensates for DPCH Crusher's inner/outer cone liner wear, all operable via a user-friendly control panel.

DPCH Cone Crusher (DPCH Crusher) features a compact design that reduces oil pipes, circuits and external adjustment components, DPCH Cone Crusher (DPCH Crusher) boasts a sleek appearance, small footprint and light weight without compromising production capacity, pioneering advancements in China’s single-cylinder hydraulic cone crusher (DPCH crusher) development.

Engineered for modern mining and construction needs, single-cylinder hydraulic cone crusher (DPCH crusher) integrates dynamic cone positioning, CSS adjustment, automated chamber cleaning, tramp iron protection and overload safeguards, ensuring single-cylinder hydraulic cone crusher's (DPCH crusher) simple operation and reliable performance in extreme working conditions.

DPCH Single Cylinder Hydraulic Cone Crusher (DPCH Cone Crusher): Engineering Advantages

1. World-Class DPCH Single Cylinder Hydraulic Cone Crusher (DPCH Cone Crusher) Technology

Featuring internationally patented hydraulic architecture, the DPCH single cylinder cone crusher (DPCH Cone Crusher) delivers unmatched operational reliability and optimized particle morphology through precision-engineered intergranular crushing dynamics.

2. Modular Performance Customization of DPCH single cylinder cone crusher (DPCH Cone Crusher)

Interchangeable chamber profiles for DPCH single cylinder hydraulic cone crusher (DPCH Crusher)

Adjustable eccentric throw of DPCH Crusher (wide operational range)

Enables flexible capacity adaptation to match specific ore characteristics and production targets.

3. Intelligent Hydraulic Optimization of single cylinder cone crusher (DPCH Crusher)

Real-time CSS adjustment under load with high precision

Continuous operation in fully choked feeding conditions

Significantly reduces wear part consumption compared to conventional systems.

4. Maintenance-Forward Design of DPCH Cone Crusher (DPCH Crusher)

Top-access service architecture (key components of DPCH Cone Crusher (DPCH Crusher) are accessible without disassembly)

Integrated hydraulic diagnostics with fail-safe overload protection

Streamlines maintenance workflows for efficient servicing of DPCH Cone Crusher (DPCH Crusher).

Technical parameters of DPCH Single Cylinder Cone Crusher (DPCH Crusher)

Model | Maximum Feeding Particle Size (mm) |

Adjustment range of Discharge port | Motor Power (kw) | Production Capacity (t/h) | Equipment Weight (t) |

DPCH 430 | 185 | 5-38 | 160 | 126-344 | 9.2 |

DPCH 440 | 215 | 6-44 | 250 | 114-395 | 21 |

DPCH 660 | 275 | 10-51 | 315 | 177-662 | 31 |

DPCH 870 | 300 | 10-70 | 630 | 588-1512 | 58 |

DPCH 890 | 366 | 13-70 | 750 | 594-2181 | 85 |

DPCS 430 | 360 | 19-51 | 132 | 91-344 | 12 |

DPCS 440 | 450 | 25-34 | 250 | 267-601 | 20 |

DPCS 660 | 560 | 38-83 | 315 | 318-1050 | 36 |

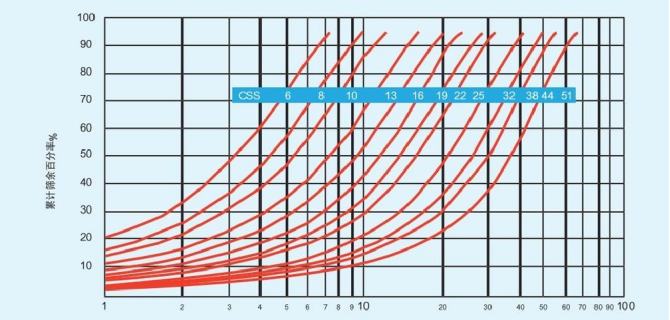

Model | Motor Installation Power (KW) | Cavity Type | Maximum Feeding particle Size (mm) | DPCH Crusher Standard Production Capacity (t/h) under the Tight Side Discharge Port css (mm) | ||||||

4 | 6 | 8 | 10 | 13 | 16 | 19 | ||||

DPCH 430 |

160 | EC | 185 |

|

|

|

| 69-108 | 75-150 | 80-161 |

C | 145 |

|

|

|

| 66-131 | 71-142 | 76-152 | ||

MC | 115 |

|

|

| 57 | 62-140 | 67-151 | 72-162 | ||

M | 90 |

|

|

| 64-84 | 69-131 | 75-142 | 80-152 | ||

MF | 75 |

|

| 61 | 65-106 | 70-115 | 76-124 | 81-126 | ||

| 50 |

| 48-78 | 51-83 | 54-88 | 59-96 | 63-103 | 68-105 | ||

DPCH 440 |

250 | EC | 215 |

|

|

|

|

| 114-200 | 122-276 |

C | 175 |

|

|

|

| 101 | 109-218 | 117-292 | ||

MC | 140 |

|

|

|

| 97-122 | 105-262 | 113-282 | ||

M | 110 |

|

|

|

| 117-187 | 126-278 | 136-298 | ||

MF | 85 |

|

|

| 114 | 124-227 | 134-245 | 144-263 | ||

| 70 |

|

| 90-135 | 96-176 | 104-191 | 112-206 | 120-221 | ||

DPCH 660 |

315 | EC | 275 |

|

|

| 209-505 |

| 177 | 190-338 |

C | 215 |

|

|

|

|

| 171-190 | 184-367 | ||

MC | 175 |

|

|

|

|

| 162-253 | 174-426 | ||

M | 135 |

|

|

|

|

| 197-295 | 211-440 | ||

MF | 115 |

|

|

|

| 192 | 207-369 | 222-396 | ||

F | 85 |

|

|

|

| 195-304 | 210-328 | 225-352 | ||

EF | 65 |

|

|

|

| 211-293 | 227-316 | 244-298 | ||

DPCH 870 |

630 | EC | 300 |

|

|

|

|

|

|

|

C | 240 |

|

|

|

|

|

| 406 | ||

MC | 195 |

|

|

|

|

|

| 443-740 | ||

M | 155 |

|

|

|

|

|

| 432-733 | ||

MF | 100 |

|

|

|

|

| 398-694 | 421-716 | ||

| 90 |

|

|

|

| 357-595 | 385-656 | 414-704 | ||

EF | 80 |

|

|

|

| 304-517 | 328-558 | 352-598 | ||

DPCH 890 |

750 | EC | 366 |

|

|

|

|

|

|

|

C | 327 |

|

|

|

|

|

|

| ||

MC | 259 |

|

|

|

|

|

| 542-817

| ||

| Model | Cavity Type | DPCH Crusher Standard Production Capacity (t/h) under the Tight Side Discharge Port css (mm) | ||||||||||||

22 | 25 | 32 | 38 | 44 | 51 | 57 | 64 | 70 | |||||||

DPCH 430 | EC | 86-171 | 91-182 | 104-208 | 115-208 |

| |||||||||

81-162 | 86-173 | 98-197 | 109-150 |

| |||||||||||

MC | 77-173 | 82-184 | 93-145 |

| |||||||||||

M | 86-162 | 91-154 | 104 |

| |||||||||||

MF | 87-114 | 92 |

| ||||||||||||

72-95 | 77 |

| |||||||||||||

DPCH 440 | EC | 131-294 | 139-313 | 159-357 | 175-395 | 192-384 |

| ||||||||

125-312 | 133-332 | 151-378 | 167-335 | 183-229 |

| ||||||||||

MC | 120-301 | 128-320 | 146-328 | 161-242 |

| ||||||||||

M | 145-318 | 154-339 | 176-281 | 194 |

| ||||||||||

MF | 153-281 | 163-299 | 186-248 |

| |||||||||||

129-236 | 137-251 | 156-208 |

| ||||||||||||

DPCH Crusher |

DPCH 660 | EC | 203-436 | 216-464 | 246-547 | 272-605 | 298-662 | 328-511 |

| ||||||

196-480 | 209-510 | 238-582 | 263-643 | 288-512 | 317-353 |

| |||||||||

MC | 186-455 | 198-484 | 226-552 | 249-499 | 273-364 |

| |||||||||

M | 226-470 | 240-500 | 274-502 | 302-403 |

| ||||||||||

MF | 237-423 | 252-450 | 278-451 | 318-363 |

| ||||||||||

241-376 | 256-400 | 292-401 | 323 |

| |||||||||||

EF | 261-290 |

| |||||||||||||

DPCH 870 | EC | 448-588 | 477-849 | 544-968 | 601-1070 | 658-1172 | 725-1291 | 782-1393 | 849-1512 | 906-1331 | |||||

C | 483-806 | 511-893 | 525-1018 | 581-1125 | 636-1232 | 700-1357 | 756-1464 | 820-1461 | 876-1286 | ||||||

MC | 476-793 | 502-857 | 522-994 | 544-1055 | 596-1155 | 657-1272 | 708-1373 | 769-1370 | 821-1206 | ||||||

M | 468-786 | 495-836 | 519-953 | 533-1054 | 558-1154 | 592-1271 | 686-1372 | 710-1248 | 765-1098 | ||||||

MF | 454-765 | 482-814 | 507-928 | 522-942 | 538-1021 | 572-1070 |

|

|

| ||||||

| 442-752 | 470-800 | 495-912 | 517-857 | 529-788 |

|

|

|

| ||||||

EF | 376-639 | 405-710 | 455-775 | 503-728 | 551-669 |

|

|

|

| ||||||

DPCH 890 | EC |

| 594-859 | 649-1309 | 696-1446 | 743-1584 | 798-1745 | 846-1883 | 801-2043 | 748-2181 | |||||

C | 697 | 622-974 | 682-1404 | 732-1552 | 783-1700 | 842-1873 | 893-2020 | 952-2193 | 812-2140 | ||||||

MC | 625-952 | 689-1232743-1404 | 790-1552 | 836-1700 | 891-1873 | 937-2020 | 992-2005 | 963-1739 | |||||||

Note: The above parameter table is for reference only.

The actual production capacity is determined by the type of materials and production conditions.

Application scenarios of DPCH Single Cylinder Hydraulic Cone Crusher (DPCH Cone Crusher)

Mineral extraction: Metalliferous/non-metalliferous quarries

Aggregates production: Sand/gravel resource utilization

Industrial processing: Construction material manufacturing, infrastructure development, and heavy machinery applications.

FAQ of DPCH Single Cylinder Cone Crusher (DPCH Cone Crusher)

1. Core positioning & advantages of DPCH Single Cylinder Cone Crusher (DPCH Cone Crusher)?

Specialized in secondary crushing, adopts large-eccentricity DPCH Crusher's single-cylinder hydraulic system for strong crushing force. Heavy-load resistant structure with thickened alloy key parts, ideal for mines and large aggregate plants with DPCH Crusher's continuous high-load operations.

2. Applicable industries & materials?

Serves mining (metal/non-metallic ores) and large construction aggregate processing. DPCH Crusher can efficiently crush granite, basalt, iron ore, quartzite. DPCH Crusher is suitable for scenarios requiring stable particle size after secondary crushing.

3. Key parameters for DPCH Crusher model selection?

Focus on material's single-particle compressive strength and hourly capacity fluctuation. DPCH Crusher's hydraulic pressure adjustable; technical team recommends models based on subsequent fine crushing feed requirements.

4. Logistics & delivery solutions about DPCH Cone Crusher?

FOB as preferred mode. Provides split packaging + port hoisting guidance. Cooperates with designated logistics providers, offering center-of-gravity parameters and hoisting diagrams for safe loading/unloading.

Our Service of DPCH Crusher

Customized Secondary Crushing Adaptation of DPCH Cone Crusher

In-depth research on the entire production chain, designs exclusive process parameters (crushing gap, speed matching) and layout suggestions for seamless connection with front-end/back-end DPCH Crusher.

Heavy-Load Logistics Support of DPCH Crusher

Adds moisture-proof and shock-proof buffer layers. Offers full-process tracking and assists in connecting hoisting resources, shortening DPCH Crusher's unloading preparation time.

Certificates