- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

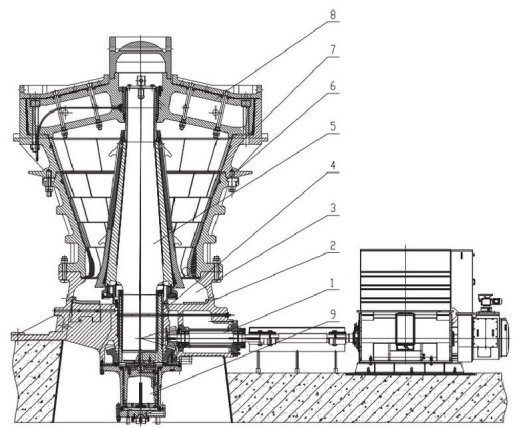

Diagram of PXZ Rotary Crusher (PXZ Hydraulic Gyratory Crusher)

1. Driving part 2. Engine base 3. Engine base guard plate

4. Eccentric sleeve 5. Moving cone 6. Middle frame body

7. Upper frame body 8. Beam part 9. Cylinder part

Introduction of PXZ Hydraulic Rotary Crusher (PXZ Hydraulic Gyratory Crusher)

Dapeng Heavy's PXZ rotary crusher (PXZ Gyratory Crusher) is mainly applied in large and ultra-large primary crushing. PXZ Gyratory Crusher has unique crushing chamber design of the DP series can ensure the best production capacity. Compared with traditional hydraulic crusher, the PXZ hydraulic rotary crusher (PXZ Gyratory Crusher) has higher crushing efficiency, lower cost, easy maintenance and adjustment. PXZ hydraulic rotary crusher (PXZ Gyratory crusher) can provide customs with an intelligent ultra-large production capacity coarse crushing solution. PXZ hydraulic rotary crusher (PXZ Gyratory Crusher) is widely used in the fields of black and non-ferrous mines and sand and gravel aggregates. The PXZ hydraulic rotary crusher (PXZ Gyratory Crusher) has equipped with an intelligent control system, PXZ hydraulic rotary crusher is not only improves the automation level but also PXZ Hydraulic Gyratory Crusher can maximize the stability of PXZ Hydraulic Gyratory Crusher operation and improves the convenience of PXZ Hydraulic Gyratory Crusher operation and maintenance.

Technical Parameters of PXZ Rotary crusher (Gyratory Crusher)

Model |

Minimum Discharge Port (mm) |

Maximum Feed Particle Size (mm) | Ajusting Range of Discharge Port (mm) | Production Capacity (t/h) | Motor Power (kw) |

PXZ-0913 | 130 | 750 | 130-160 | 625-770 | 210 |

PXZ-1216 | 160 | 1000 | 160-190 | 1250-1480 | 400 |

PXZ-1417 | 170 | 1200 | 170-200 | 1750-2260 | 560 |

PXZ-1618 | 190 | 1350 | 190-215 | 2400-3350 | 800 |

DP-4265 | 152 | 1066 | 152-177 | 2354-2893 | 450 |

DP-5065 | 152 | 1270 | 152-177 | 2414-2958 | 450 |

DP-5475 | 152 | 1370 | 152-177 | 2908-3170 | 600 |

DP-6275 | 152 | 1575 | 152-177 | 2913-3846 | 600 |

DP-6089 | 177 | 1525 | 177-203 | 4576-5851 | 750 |

DP-7089 | 177 | 1780 | 177-203 | 5051-7033 | 9 |

Note: The above parameter table is for reference only.

The actual production capacity is determined by the type of materials and production condition.

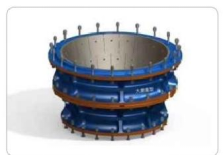

Parts of PXZ Hydraulic Rotary Crusher (Gyratory Crusher)

Application scenarios of PXZ Rotary Crusher (Gyratory Crusher)

1. Large and medium-sized ore dressing plants and large quarries

2. Coarse crushing operation: PXZ Hydraulic Gyratory Crusher is a coarse crusher.

3. Industrial coarse crushing of various hard materials

4. Continuous crushing and ore discharging

PXZ Hydraulic Gyratory Crusher is widely used in large and medium-sized ore dressing plants and large quarries for crushing hard and medium-hard ores due to its large production capacity and continuous crushing of ore. As well as the production capacity of PXZ hydraulic gyratory crusher (Rotary crusher) is 3~4 times higher than a jaw crusher.

FAQ of PXZ Gyratory Crusher

1. What are the core advantages of this PXZ Hydraulic Rotary Crusher (PXZ Gyratory Crusher)?

It significantly boosts capacity, efficiency and maintenance convenience, shortens downtime, suits large-scale primary crushing, and balances long-term stable operation with high productivity.

2. Which industries and materials is PXZ Hydraulic Rotary Crusher (Gyratory Crusher) suitable for?

PXZ Gyratory Crusher is widely used in mining, construction aggregates, metallurgical beneficiation, etc. It can crush granite, basalt, limestone, iron ore and other hard materials, flexibly meeting primary crushing needs across industries.

3. How to select the right model of PXZ Hydraulic Rotary Crusher (Gyratory Crusher) for specific needs?

We offer professional sizing services. Based on your industry, capacity goals, material hardness, desired output size and other key parameters, we accurately match the optimal model to ensure full alignment with production requirements.

Our Service of PXZ Hydraulic Gyratory Crusher (PXZ Rotary Crusher)

1. Customized Consultation of PXZ Hydraulic Gyratory Crusher (PXZ Rotary Crusher)

Needs Assessment: Our technical team will conduct in-depth communication with you to understand your project requirements, including daily output expectations, material characteristics (hardness, particle size of iron ore, granite, basalt, copper ore, etc.), and crushing stage (primary or secondary crushing), so as to recommend the most suitable PXZ Hydraulic Rotary Crusher model and configuration.

Solution Design: For large-scale mining, metallurgical beneficiation or bulk aggregate production lines, we can provide matching suggestions for the integration of the PXZ Hydraulic Rotary Crusher with your existing equipment (feeders, conveyors, screening equipment, washing equipment), ensuring seamless connection and optimized overall production efficiency.

2. Professional Support of PXZ Hydraulic Gyratory Crusher (PXZ Rotary Crusher)

Production Progress Tracking of PXZ Hydraulic Gyratory Crusher: After order confirmation, we will regularly update you on the manufacturing progress of PXZ Hydraulic Gyratory Crusher, including the production status of core components (gyratory crushing cone, concave, main shaft, hydraulic control system) and the estimated delivery time, keeping you fully informed.

3. Logistics & Packaging Guarantee of PXZ Rotary Crusher (PXZ Rotary Crusher)

We cooperate with trustworthy international logistics providers to offer flexible transportation solutions (FOB, CIF, etc.) to ensure it is delivered to your designated site intact and on time.

4. We provide technical documents related to PXZ Hydraulic Gyratory Crusher, including operation manuals, installation diagrams, and troubleshooting guides, which specify PXZ Hydraulic Gyratory Crusher working principle, PXZ Hydraulic Gyratory Crusher operation steps, PXZ Hydraulic Gyratory Crusher discharge port adjustment methods, and PXZ Hydraulic Gyratory Crusher common problem solutions (such as uneven product particle size, hydraulic system pressure abnormality) for your reference.

Our Company

Dapeng is one of the most famous companies in the field of crusher in China, specializing in the production of crushing and mineral processing machinery, integrating design and development, processing and manufacturing, pre-sales and after-sales service.

Dapeng has more than 200 employees, more than 30 middle and senior technical personnel, more than 35,000 square meters of standardized plant. Crusher developed by Dapeng is widely used in mining, cement, highway, electric power, metallurgy and other industries.

Our core products are PXZ rotary crusher, European jaw crusher, DPCS/DPCH hydraulic cone crusher, DPHP hydraulic cone crusher, PYS Symons cone crusher, VSI crusher, ball mill, heavy apron feeder, vibrating feeder and vibrating screen. As well as premium OEM-quality standard parts compatible with popular brands, such as Metso HP series, Sandvik CH/CS cone crushers, and more.

Shenyang Dapeng adheres to the survival principle of leading technology, reliable quality, reasonable price and considerate service, adheres to the enterprise spirit of "professionalism, efficiency and pragmatism", and takes customer satisfaction as the goal. We warmly welcome customers at home and abroad to visit us for guidance, consultation and negotiation.

Certificates