- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

1. MQY Ball Mill is designed with a suitable ratio of barrel diameter and length. 2. There is no complicated grating plate at the discharge end of MQY Ball Mill, and the structure is simple, which is easy to manage and repair. 3. MQY Ball Mill can ensure the wear resistance and service life of the equipment.

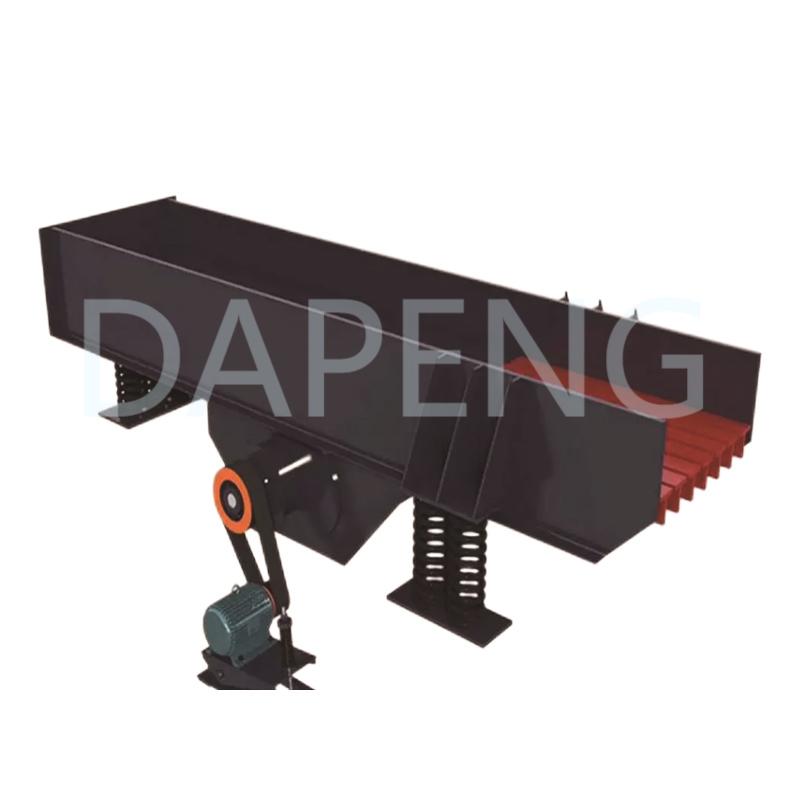

1.The Heavy Feeder is an indispensable device in the fields of mining, metallurgy, building materials, and coal. In actual operation scenarios, the Heavy Feeder is often installed below silos and hoppers with a certain storage pressure. It can smoothly convey various materials with high bulk density over a short distance to equipment such as crushers and screeners. Especially in the primary crushing stage, the Heavy Feeder can fully exert Heavy Feeder effectiveness. 2.This Heavy Feeder has strong adaptability in terms of performance. Whether it is coarse materials or fine-grained materials, the GBZ plate feeder can handle them properly. Even in harsh environments, in the face of changes in the particle size composition of materials and significant fluctuations in temperature, the GBZ plate feeder can still remain stable and complete the feeding work reliably and uniformly. 3.When operating the GBZ heavy-duty heavy plate feeder, strict compliance with the operating specifications is required. It is strictly prohibited to let the materials be emptied, and it is forbidden for large pieces of materials to directly impact the chain plate surface of the GBZ plate feeder. Moreover, blasting operations on the chain plate surface are not allowed. The installation inclination angle of the GBZ plate feeder ranges from 0° to 25°, and the transmission device can be installed on the left or right according to actual needs. When the transmission device is located on the right side of the material running direction, this GBZ plate feeder is a right-drive type; conversely, it is a left-drive type.

1. ZSW vibrating feeder is designed based on the principle of generating exciting force by eccentric vibration of the shaft, which has stable vibration and realizes balanced production of the production line. 2. ZSW vibrating feeder can effectively prevent material blockage while feeding. 3. ZSW vibrating feeder can be equipped with speed regulating motor to facilitate the control of feeding amount, low noise during working process, which is conducive to improving working environment.

1. The VSI crusher adopts a unique vertical shaft design, which can achieve efficient material crushing. 2. The VSI crusher can handle various types of materials, especially suitable for the production of artificial sand and building aggregates. 3. The design of the VSI crusher effectively reduces energy consumption and meets environmental protection requirements.

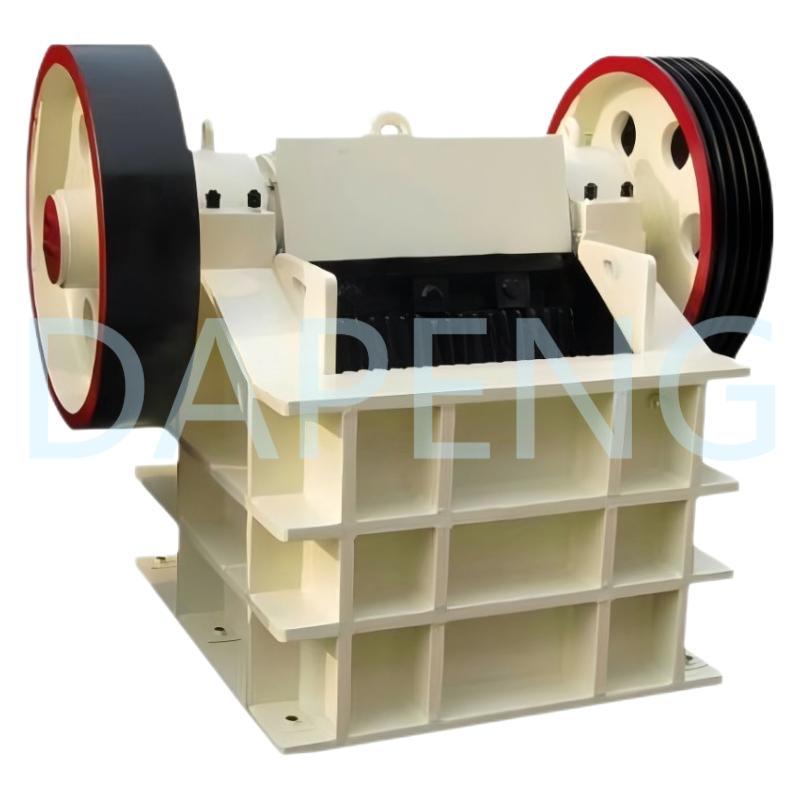

1.PEF Jaw Crusher ensures that materials can pass through the crushing chamber more effectively, thereby improving the overall crushing efficiency. 2.PEF Jaw Crusher has a large crushing ratio and uniform product particle size. 3.PEF Jaw Crusher has a simple structure, reliable operation and low operating costs.

OEM quality standard parts to fit MP/HP/GP/C, CH/CS, Symons, etc.