- Home

- Products

- Case

- Factory Show

- News

- video

- About Us

- Contact Us

1. PYS symons cone crusher adopts the principle of lamination crushing, which increases the proportion of cubes in the finished product, reduces the content of needle-like flakes, and makes the particle size more uniform. 2. PYS symons cone crusher equipment has a complete lubrication system, which can automatically shut down when the oil temperature is too high or the flow rate is too slow, protecting the equipment and extending the service life. 3. PYS symons cone crusher has a simple structure, easy operation, and reduces downtime. The wearing parts are made of special materials, which are durable and have low operating costs.

1. PYT spring cone crusher has large crushing force and can provide greater production capacity under the same machine weight. 2. PYT spring cone crusher has less consumption of wearing parts, low operating cost, and has hydraulic protection and hydraulic cavity cleaning functions, high degree of automation, and reduced downtime. 3. PYT spring cone crusher adopts modular design. By changing the cavity type, it can realize the conversion of coarse, medium and fine crushing, and the operation is flexible.

1. DP Single Cylinder Hydraulic Cone Crusher has uniform particle shape and high output. With its optimized cavity design and laminated crushing principle, it can produce high-quality cubic particles with more uniform particle shape while maintaining high production capacity. 2. DP Single Cylinder Hydraulic Cone Crusher has strong crushing capacity and stable operation. At the same time, its continuous and stable operation capacity and automatic overload protection function protect the equipment during processing. 3. DP Single Cylinder Hydraulic Cone Crusher has automatic overload protection and efficient rotary feeding device, which can automatically adjust when overload is detected, extending the service life of the equipment.

The DP CS Series Single Cylinder Hydraulic Cone Crusher features high production capacity, uniform particle shape, and advanced hydraulic/lubrication systems, while offering easy operation, low operating costs, and a compact structural design.

1. The VSI crusher adopts a unique vertical shaft design, which can achieve efficient material crushing. 2. The VSI crusher can handle various types of materials, especially suitable for the production of artificial sand and building aggregates. 3. The design of the VSI crusher effectively reduces energy consumption and meets environmental protection requirements.

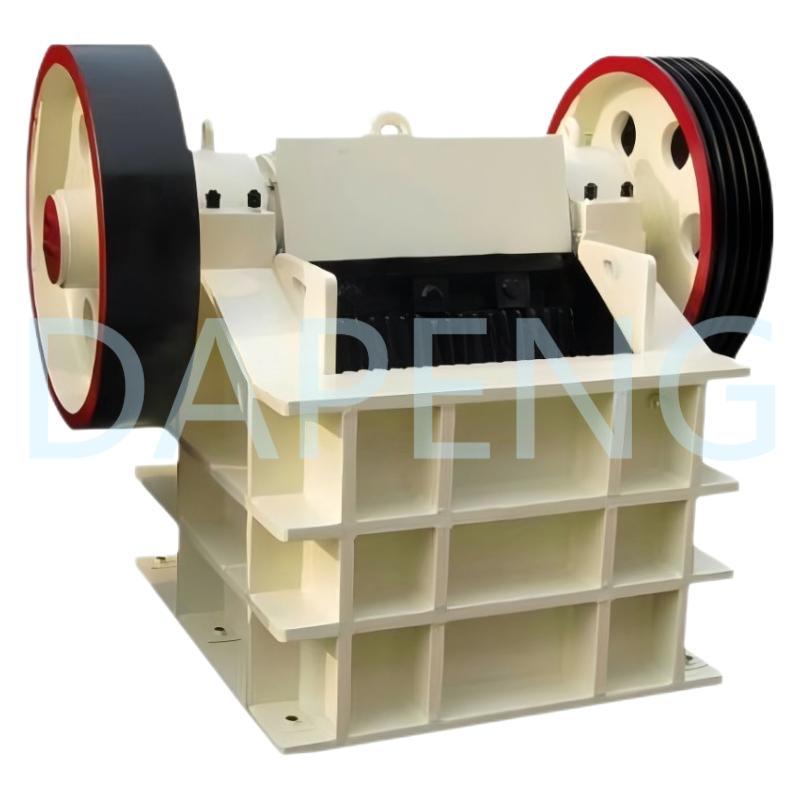

1.PEF Jaw Crusher ensures that materials can pass through the crushing chamber more effectively, thereby improving the overall crushing efficiency. 2.PEF Jaw Crusher has a large crushing ratio and uniform product particle size. 3.PEF Jaw Crusher has a simple structure, reliable operation and low operating costs.